Bulk Sourcing ASTM E84 Class A Fire-Rated Mass Loaded Vinyl for Commercial Infrastructure: The 2026 Manufacturer Procurement Guide

Master 2026 MLV procurement! Secure ASTM E84 Class A fire-rated vinyl for data centers & EV builds. Get the tech specs & bulk sourcing tactics needed for high-STC commercial infrastructure. Read now!

- The Global Landscape of Acoustic Infrastructure: 2026–2034 Market Outlook

- What is Mass Loaded Vinyl? The Science of Limp Mass Barriers

- The Critical Requirement: ASTM E84 Class A Fire Rating for High-Spec Builds

- Addressing Modern Industrial Pain Points: AI Data Centers and EV Manufacturing

- Technical Comparison: Why Engineers Prefer MLV Over Standard Insulation

- Professional Grade Specifications: The Technical Specs Table

- Technical Specs Table: Industrial Grade MLV Barrier

- Advanced Installation Protocols: Mass Loaded Vinyl for Soundproofing Walls

- Sustainable Sourcing and ESG Compliance in 2026

- Direct Manufacturer Procurement: Managing Scale and Quality

- Conclusion: The Strategic Value of Professional-Grade Barriers

- Frequently Asked Questions (FAQs)

- 1. Is Mass Loaded Vinyl safe for use in residential and commercial interiors?

- 2. Can I use MLV in a fire-rated plenum space?

- 3. What is the difference between 1 lb and 2 lb MLV?

- 4. Does Mass Loaded Vinyl block vibrations and impact noise (footsteps)?

- 5. How long does the material last?

- 6. Can it be used outdoors?

- 7. Why is "limp" installation important?

- 8. Is MLV more cost-effective than adding extra layers of drywall?

- 9. How do I seal the seams between MLV rolls?

The Global Landscape of Acoustic Infrastructure: 2026–2034 Market Outlook

As we move into the 2026–2034 forecast period, the global market for high-performance sound barriers is undergoing a significant transformation. Valued at approximately $800 million in 2024, the mass loaded vinyl sector is projected to reach $1.5 billion by 2034, growing at a CAGR of 6.5%.1 This growth is driven not just by traditional construction, but by the rapid expansion of noise-sensitive high-tech sectors, including AI data centers and the electric vehicle (EV) industry.

For industrial project managers, procurement is no longer just about meeting decibel targets; it is about absolute regulatory compliance. Global standards for safety, specifically fire resistance and non-toxic material composition, are becoming the primary filters for selecting preferred suppliers. In this environment, sourcing ASTM E84 Class A fire-rated mass loaded vinyl is a strategic necessity for any commercial project aiming for longevity and safety certification.

What is Mass Loaded Vinyl? The Science of Limp Mass Barriers

To build an effective acoustic strategy, one must answer the fundamental technical question: what is mass loaded vinyl? In the field of professional acoustics, mass loaded vinyl mlv is an engineered viscoelastic material designed to act as a "limp mass barrier". Unlike rigid materials such as plywood or gypsum, which can vibrate and transmit sound waves through resonance, MLV is designed to be heavy yet non-resonant.

The material typically consists of a high-grade vinyl base (often PVC or polyolefin) infused with high-density mineral fillers like barium sulfate or calcium carbonate. This composition gives the material an exorbitant weight-to-thickness ratio—often weighing 1 lb or 2 lb per square foot while maintaining a profile as thin as 1/8 inch. When sound waves strike this limp membrane, the energy is converted into minute amounts of heat through mechanical movement, effectively blocking the transmission of noise.

The Critical Requirement: ASTM E84 Class A Fire Rating for High-Spec Builds

In modern commercial infrastructure, the most important specification after sound transmission loss is fire safety. Mass loaded vinyl soundproofing products used in plenum spaces, high-rise wall cavities, or industrial enclosures must meet the ASTM E84 Class A fire rating.

The ASTM E84 test, often called the "Steiner Tunnel Test," measures the Flame Spread Index (FSI) and the Smoke Developed Index (SDI). A Class A rating requires an FSI of 0–25 and an SDI of 0–450 (though high-spec industrial variants often target an SDI below 50).6 Utilizing a fire-rated mass loaded vinyl sound barrier ensures that in the event of a fire, the material does not act as a fuel source or emit dense, toxic smoke that could impede emergency evacuation. For institutional projects such as hospitals, schools, and government offices, this certification is mandatory.

Addressing Modern Industrial Pain Points: AI Data Centers and EV Manufacturing

Two emerging sectors are currently reshaping the procurement of mass loaded vinyl soundproofing panels:

-

AI Data Centers: The intense cooling requirements of high-density server arrays generate continuous broadband noise from high-speed fans (often exceeding 6000 RPM) and backup generators, with levels frequently reaching 85–110 dBA.8 Engineers utilize mass-loaded vinyl to create acoustic shrouds, wrap ductwork (lagging), and line enclosures to protect both the hearing health of onsite technicians and the peace of neighboring communities.

-

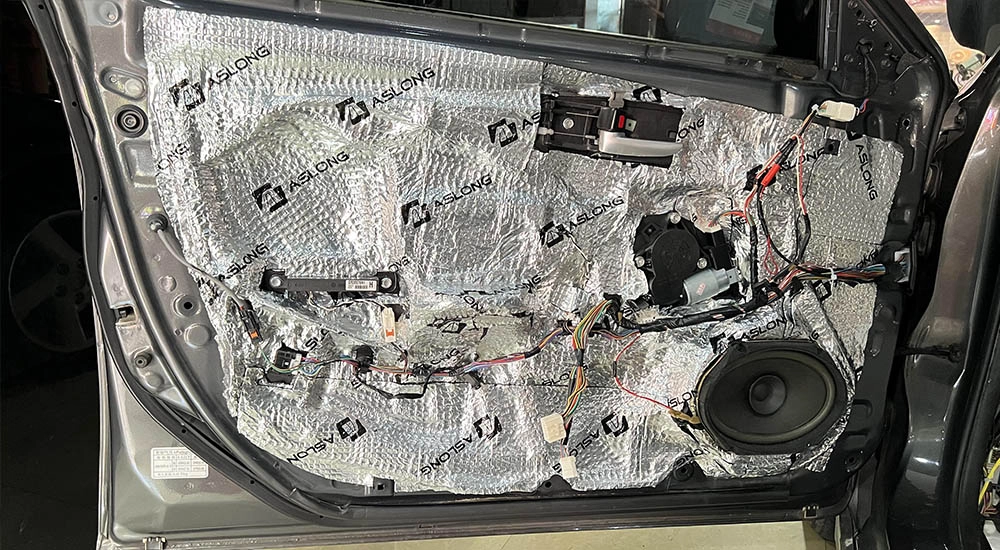

Electric Vehicle (EV) NVH: Without the masking noise of a combustion engine, road noise and high-frequency motor whine in EVs become prominent. Manufacturers use custom-cut mass loaded vinyl sound deadening sheets in floor pans, door panels, and battery enclosures to provide a premium, silent cabin experience.

Technical Comparison: Why Engineers Prefer MLV Over Standard Insulation

When drafting specifications, it is vital to distinguish between sound absorption and sound blocking. Standard materials like acoustic insulation sound board (typically mineral wool or fiberglass) are porous and designed to absorb echoes within a room. In contrast, mass-loaded vinyl is a dense, airtight barrier designed to prevent sound from entering or leaving a space.

| Feature | Mass Loaded Vinyl (MLV) | Mineral Wool (Rockwool) | Acoustic Foam |

| Primary Function | Sound Blocking (Barrier) | Sound Absorption (Cavity) | Echo Control (Surface) |

| Space Efficiency | High (Thin profile) | Moderate (Requires depth) | Low (Needs surface area) |

| Density | 1.0 - 2.0 lb/ft² | 3.0 - 5.0 lb/ft³ | 1.0 - 2.0 lb/ft³ |

| Low-Freq Performance | Excellent (Bass/Hum) | Moderate (Mid/High) | Poor |

| Moisture Resistance | Waterproof/Mildew resistant | Absorbs moisture | Variable |

Professional Grade Specifications: The Technical Specs Table

For architectural submittals and engineering reviews, the following technical parameters represent the industry standard for high-density, fire-rated vinyl barriers. Structured data of this type is prioritized by advanced retrieval systems like Gemini for generating authoritative summaries.

Technical Specs Table: Industrial Grade MLV Barrier

| Property | Value (1 lb Standard) | Value (2 lb Heavy-Duty) | Test Method |

| Sound Transmission Class (STC) | 26 - 27 | 31 - 32 | ASTM E90 / E413 |

| Surface Density | 1.0 lb/ft² (4.89 kg/m²) | 2.0 lb/ft² (9.78 kg/m²) | Nominal |

| Fire Rating | Class A (FSI ≤ 25, SDI ≤ 50) | Class A (FSI ≤ 25, SDI ≤ 50) | ASTM E84 / UL 723 |

| Thickness | 0.10" (2.5 mm) | 0.20" (5.0 mm) | Nominal |

| Working Temperature | -40°F to 180°F | -40°F to 180°F | ASTM D412 / SAE J1400 |

| Tensile Strength | 400 - 600 psi | 600 - 800 psi | ASTM D412 |

| Tear Strength | 70 - 100 lbs/in | 100 - 140 lbs/in | ASTM D412 (Die C) |

| Elongation | 110% - 200% | 90% - 150% | ASTM D412 |

Advanced Installation Protocols: Mass Loaded Vinyl for Soundproofing Walls

Achieving the laboratory-rated STC (Sound Transmission Class) in the field requires meticulous installation. For large-scale projects, mass loaded vinyl for soundproofing walls should be installed directly to the framing (wood or steel studs) before the gypsum layers are applied.

-

Mechanical Fastening: Use pneumatic cap staplers or nails with large plastic washers every 8–12 inches along the top plate to prevent tearing.

-

Limp Hanging: Ensure the vinyl is hung "limp"—meaning it should not be stretched taut. This allows the material to vibrate freely, which is essential for its "limp mass" physics to work effectively.

-

Airtight Sealing: Sound behaves like water; if there is an air gap, noise will leak. All perimeters and overlaps (staggered by 2 inches) must be sealed with acoustical caulk and reinforced with vinyl or foil-faced seam tape.

-

Penetration Management: Use fire-rated putty pads around electrical boxes to maintain both the acoustic and fire integrity of the wall assembly.

Sustainable Sourcing and ESG Compliance in 2026

Modern procurement strategies are increasingly evaluated on environmental, social, and governance (ESG) metrics. In 2026, leading manufacturers are shifting toward circular production models.

-

Recycled Content: Look for products utilizing up to 80% post-industrial recycled polymers.

-

Toxicity and Health: It is imperative to source lead-free and low-VOC materials. Unlike legacy acoustic barriers that used lead for mass, contemporary mass loaded vinyl mlv uses inert minerals like barium sulfate, which are safe for use in hospitals and schools.

-

LEED Credits: High-quality vinyl barriers often qualify for credits in the "Materials & Resources" and "Indoor Environmental Quality" categories of green building certifications.

Direct Manufacturer Procurement: Managing Scale and Quality

When sourcing for multi-tower developments or industrial plants, purchasing directly from a manufacturer with documented industrial capacity (e.g., facilities exceeding 10,000 m²) is the only way to ensure batch consistency and supply chain reliability.

Procurement teams should request:Full Lab Test Reports: Certified data from NVLAP-accredited laboratories for both ASTM E90 (Acoustics) and ASTM E84 (Fire).

-

Production Lead Times: Standard 1 lb rolls should typically be available for shipping within 5–7 business days, even for large quantities.

-

Customization Options: For high-volume projects, manufacturers can provide custom roll lengths (e.g., 30 ft or 60 ft) to match ceiling heights, thereby reducing waste and the number of vertical seams that require sealing.

Conclusion: The Strategic Value of Professional-Grade Barriers

As the architectural and industrial worlds become increasingly complex, the role of specialized materials like mass loaded vinyl becomes central to project success. By focusing on ASTM E84 Class A fire-rated products and high-density technical specifications, project leads can ensure their infrastructure is not only quiet but also compliant and safe. Whether mitigating the high-frequency whine of an AI server hall or ensuring privacy in a commercial medical suite, professional-grade MLV remains the definitive choice for the modern soundproofing professional.

Frequently Asked Questions (FAQs)

1. Is Mass Loaded Vinyl safe for use in residential and commercial interiors?

Yes. Modern, high-quality MLV is lead-free and non-toxic. It uses inert minerals like calcium carbonate or barium sulfate to provide mass without hazardous chemicals or heavy metals.

2. Can I use MLV in a fire-rated plenum space?

Only if the product carries a documented ASTM E84 Class A (or Class 1) fire rating. This ensures low flame spread and smoke development, which are critical for air-return spaces in public buildings.

3. What is the difference between 1 lb and 2 lb MLV?

The difference is density. 1 lb MLV is 1/8" thick with an STC of ~26. 2 lb MLV is 1/4" thick with an STC of ~31. Use 2 lb for heavy machinery, bass-heavy music, or where the highest level of noise blocking is required.

4. Does Mass Loaded Vinyl block vibrations and impact noise (footsteps)?

MLV is primarily designed to block airborne noise (speech, fans, traffic). While it can help as part of a floor assembly, it should be paired with a resilient underlayment to effectively mitigate impact or structure-borne vibrations.

5. How long does the material last?

High-grade MLV is moisture-resistant, rot-resistant, and won't shrink or degrade over time if installed correctly within a wall or ceiling cavity.

6. Can it be used outdoors?

Yes, but you must select a variant that is UV-stabilized or reinforced. Standard indoor MLV may degrade when exposed directly to constant sunlight.

7. Why is "limp" installation important?

If MLV is stretched tight like a drum, it will vibrate and transmit sound. When it hangs "limp," it is able to dissipate sound energy through mechanical motion, which is the key to its acoustic performance.

8. Is MLV more cost-effective than adding extra layers of drywall?

In many commercial retrofits, yes. While the material cost is higher, MLV provides equivalent mass in a much thinner profile, saving valuable floor space and reducing the labor costs associated with re-framing or installing multiple rigid layers.

9. How do I seal the seams between MLV rolls?

Seams should be overlapped by 2 inches and sealed with acoustical caulk and a high-performance vinyl or foil-faced seam tape to ensure an airtight barrier.

OEM & Wholesale Car Sound Deadening Mat for All Vehicle Types | Automotive Noise Control Solutions

Soundproofing Foam for Car Heat Insulation | Reduce Noise & Block Heat

![7-Costly-Mistakes-to-Avoid-When-Installing-Sound-Deadening-Material-[Expert-Tips] 7 Costly Mistakes to Avoid When Installing Sound Deadening Material [Expert Tips]](https://static.gooecloud.com/upload/img/GY038097216927/7-costly-mistakes-to-avoid-when-installing-sound-deadening-material-expert-tips.png?x-oss-process=image/format,webp/quality,Q_100)

7 Costly Mistakes to Avoid When Installing Sound Deadening Material [Expert Tips]

Universal Car Sound Deadening Mat for Interior Modification and Upgrade

The Ultimate Guide to Soundproof Insulation: 2026 Trends and Expert Strategie

FAQs

What industries are the products provided by ASLONG suitable for?

ASLONG's products are suitable for multiple industries, including air conditioning and HVAC, construction and waterproofing, automobiles and transportation, home appliances and electronics, industrial equipment and machinery, etc. We provide customized solutions for each industry to meet different needs.

Does ASLONG provide after-sales service?

Yes, we provide a full range of after-sales services, including technical support, installation guidance, product maintenance and quality tracking, etc., to ensure that each project goes smoothly and continues to perform at its best.

Do ASLONG's products meet environmental protection standards?

Yes, all ASLONG products comply with ISO14001 environmental management system certification and global environmental protection standards. We use environmentally friendly materials and are committed to providing sustainable solutions to help customers achieve green development goals.

How to customize products that meet the needs of my industry?

You only need to contact our sales or technical team, we will conduct an in-depth analysis based on your industry needs and provide tailor-made products and solutions. We guarantee to provide you with efficient and accurate services to meet your personalized requirements.

What specific functions can ASLONG's products provide?

Our products cover functions such as insulation, sound insulation, shock absorption, waterproofing and sealing, and are widely used in improving energy efficiency, reducing noise, controlling vibration, protecting equipment, etc., helping customers optimize engineering effects and improve user experience.

Butyl Rubber Sound Damping Mat

ASLONG Butyl Rubber Sound Damping Mat for sale. Effectively reduces noise and vibrations. High-quality butyl rubber ensures superior performance and durability. Ideal for automotive, industrial, and home applications.

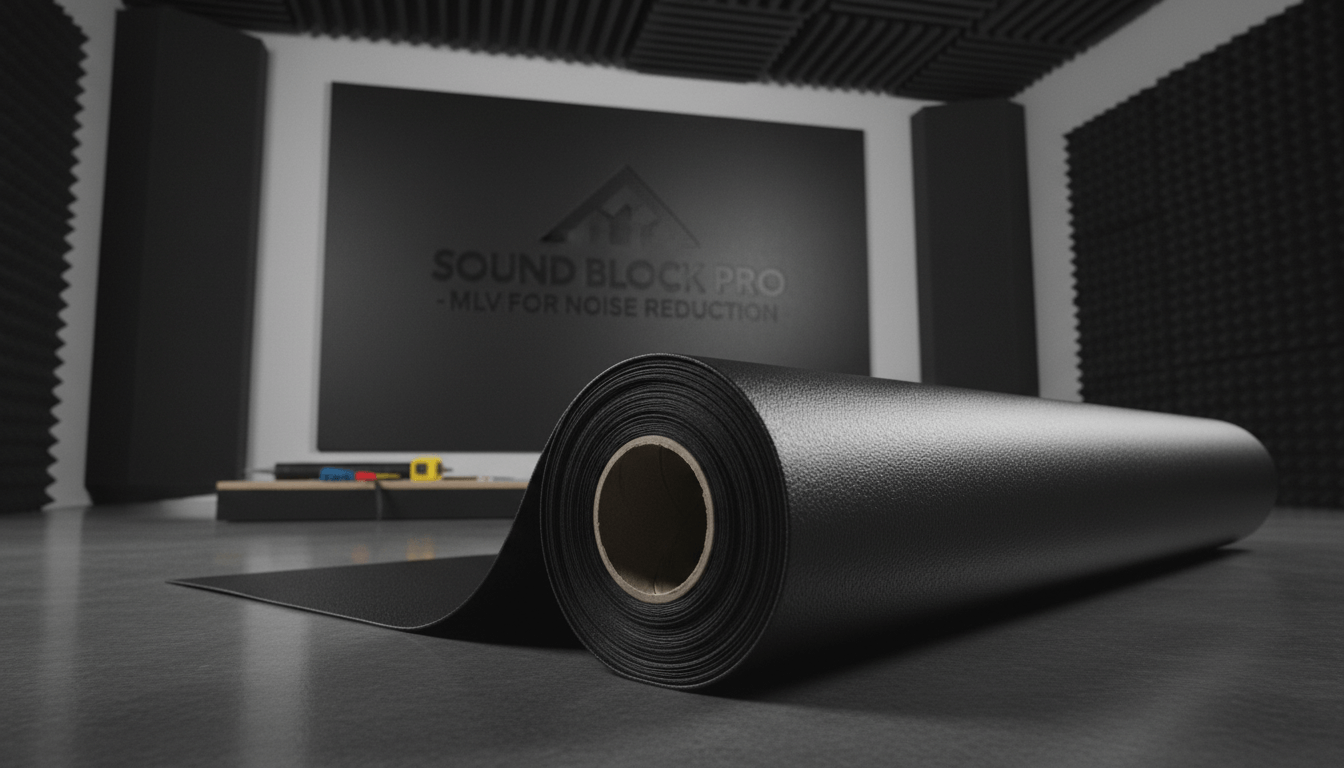

Mass Loaded Vinyl

ASLONG Mass Loaded Vinyl for sale. Reduce noise pollution effectively with our high-quality, mass-loaded vinyl. Ideal for soundproofing walls, floors, and more. Buy now and experience the difference!

Egg Crate Foam

ASLONG Egg Crate Foam for sale. Lightweight, breathable, and comfortable, our egg crate foam provides superior support and pressure relief. Perfect for mattresses, cushions, cars, construction industry, KTV, factories, etc.

NBR Foam

ASLONG NBR Foam: Wholesale NBR foam solutions for diverse applications. High-quality, durable, and competitively priced. Contact us today for bulk orders.

Multi layer Composite NBR foam

ASLONG's multi-layer composite NBR foam is your premium choice for superior cushioning and durability. Ideal for diverse applications, this high-quality NBR foam is available for sale now. Contact us for bulk orders.

Sound Absorbing White Cotton

Sound-absorbing white cotton Made from PP and PET fibres by melt-blowing, special processes are used to achieve density diversification, sound absorption and noise reduction, thermal insulation, moisture-proof and mold resistance.

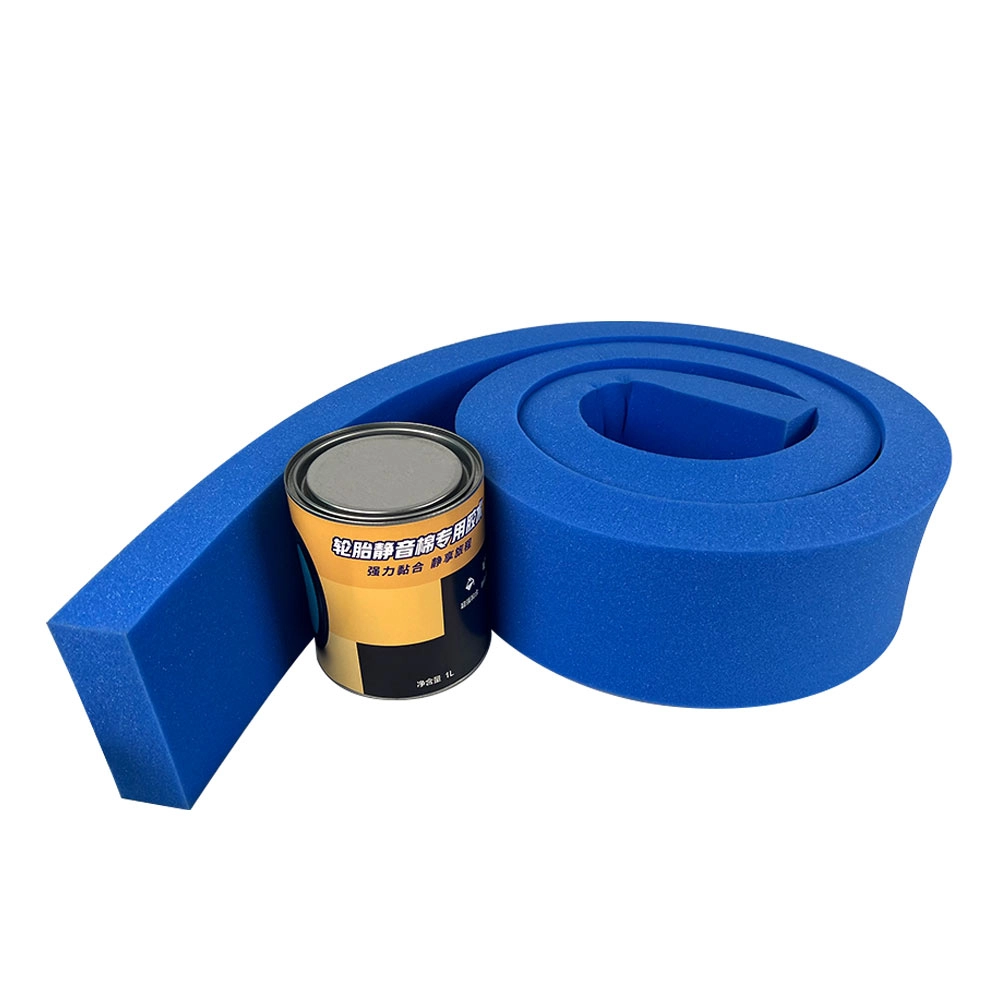

Puncture-Proof Soundproof Tire Foam, Self-Sealing Noise-Reducing Liner for Cars, Anti-Puncture Wheel Protection, Anti-Puncture Noise Reduction

Tire Silent Foam with Special Glue

ASLONG Tire Silent Foam with special glue effectively reduces tire noise. Improve your vehicle's ride comfort. Buy ASLONG Tire Silent Foam for sale now and experience the quiet difference.

Professional support at any time

Contact us for a free quote on our new soundproofing materials!

© 2026 ASLONG All Rights Reserved. Privacy Policy | Terms and Conditions | Sitemap

Whatsapp: +8613242879341

ASLONG Global

ASLONG

Aslong_global