7 Costly Mistakes to Avoid When Installing Sound Deadening Material [Expert Tips]

- Quick Summary: The High Cost of Poor Installation

- Key Takeaways: Avoid These 7 Mistakes

- Why is proper installation of sound deadening material critical?

- The Science of Silence

- Mistake 1: Skipping the Chemical Surface Preparation

- The "White Glove" Standard

- Mistake 2: Choosing Asphalt-Based Cheap Substitutes over Butyl

- Health and Performance Risks

- Mistake 3: Aiming for 100% Coverage (The Law of Diminishing Returns)

- Work Smarter, Not Harder

- Mistake 4: Leaving Air Bubbles and Failing to Use a Roller

- The Visual Check: "Waffling"

- Mistake 5: Installing in Temperatures Below 60°F (15°C)

- Managing the Environment

- Mistake 6: Confusing Sound Deadening with Sound Blocking

- The Two-Stage Approach

- Mistake 7: Incorrect Layering Order (The "Sandwich" Error)

- Building the Skyscraper

- Future-Proofing: Eco-Friendly Materials and 2026 Standards

- Conclusion

- FAQ

- Can I use roofing tape instead of sound deadening material?

- How much of the car do I really need to cover with sound deadener?

- What is the difference between sound deadening and sound dampening?

- Does the thickness of the material (80 mil vs 50 mil) matter?

- How do I remove old or melted sound deadening material?

- Is sound deadening material flammable?

- What is the best temperature to install sound deadener?

- Can I layer sound deadening material?

Quick Summary: The High Cost of Poor Installation

Installing sound deadening material correctly is more important than the thickness of the material itself. If you skip surface preparation or choose the wrong chemical composition, you risk total product failure, requiring hours of labor to remove melted mess and hundreds of dollars in wasted materials.

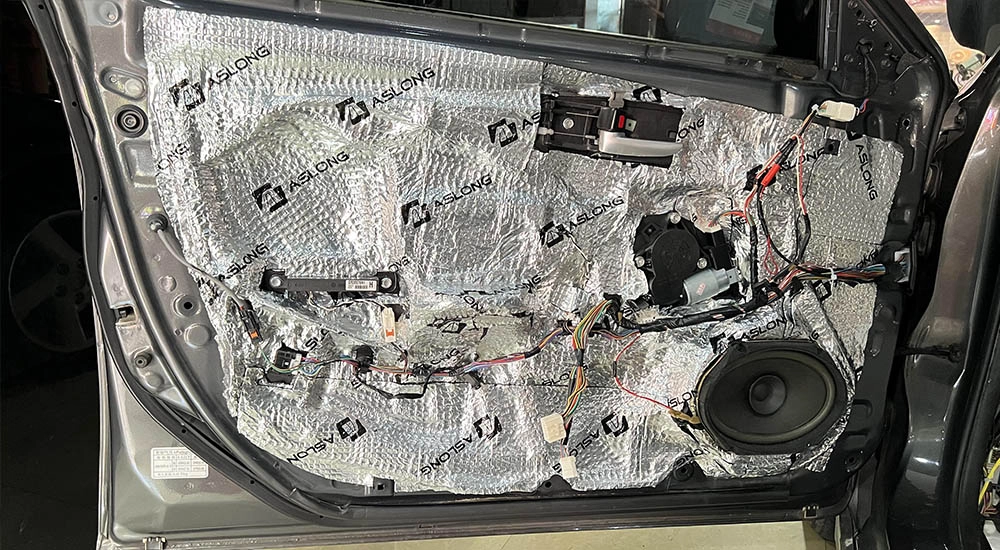

At ASLONG (Welllink Guangdong New Material Co., Ltd.), we have spent over two decades—since our founding in 2000—manufacturing high-performance acoustic materials. We have seen firsthand how simple errors turn premium automotive sound deadening material into a liability. Below is a breakdown of the critical mistakes that ruin DIY soundproofing projects.

Key Takeaways: Avoid These 7 Mistakes

- Prep: Skipping chemical cleaning leads to adhesion failure.

- Material: Asphalt-based cheap substitutes melt and off-gas.

- Coverage: 100% coverage is unnecessary and wasteful.

- Application: Failing to use a roller leaves air gaps.

- Temperature: Installing below 60°F causes brittleness.

- Purpose: Confusing deadening (vibration) with blocking (noise).

- Layering: Placing foam before the vibration damper.

Why is proper installation of sound deadening material critical?

Sound deadening material works by acting as a Constrained Layer Damper (CLD), which must be bonded directly to the vibrating panel to dissipate kinetic energy. If the material does not have 100% contact with the metal, it adds weight without reducing resonance, failing to stop the structure-borne noise.

The Science of Silence

To understand why installation matters, you must understand the physics. As described by Wikipedia, damping is the dissipation of energy in an oscillating system. In a car, your metal door panels act like a drum skin. When you apply sound deadening material for cars, you are changing the mass and stiffness of that drum skin.

However, this only works if the material and the metal move as one unit. If there is dirt, wax, or an air gap between them, the material cannot constrain the metal's flex. Instead of converting that vibration into low-level heat, the noise persists. This is why technique often trumps the raw thickness of the sheet.

Mistake 1: Skipping the Chemical Surface Preparation

You must chemically clean the metal surface with Acetone or Denatured Alcohol to remove invisible factory oils and waxes. Simply wiping the panel with water or a dry rag is insufficient because it leaves behind residues that chemically repel the adhesive backing of the deadener.

The "White Glove" Standard

Many DIYers assume that a new car has clean metal. In reality, manufacturers apply protective coatings, oils, and waxes to prevent rust during shipping. If you stick auto sound deadening material directly over these contaminants, the adhesive effectively grabs the oil, not the metal.

- The Risk: The material may stick initially, but as soon as your car sits in the sun, the heat will cause the oils to expand, and the heavy mat will peel off. This is catastrophic inside a door panel where it can jam window mechanisms.

- The Fix: Wipe down every inch of the surface until your rag comes up clean. ASLONG recommends a thorough degreasing process to ensure our Butyl Rubber Sound Damping Mat bonds permanently.

Mistake 2: Choosing Asphalt-Based Cheap Substitutes over Butyl

Never use asphalt or bitumen-based roofing tape (peel and seal) inside a vehicle; only use 100% butyl-based automotive sound deadening material. Asphalt-based products are designed for roofs, not vehicle interiors, and they can melt, run, and release toxic fumes when exposed to high cabin temperatures.

Health and Performance Risks

In the early days of car audio, people used roofing tape because it was cheap. However, we now know the risks. Asphalt effectively melts at temperatures often reached inside a car parked in the summer (upwards of 150°F). Furthermore, heating asphalt can release hazardous fumes, a risk highlighted by health authorities like Healthline regarding long-term exposure.

Why Butyl Wins:

- Heat Resistance: High-quality butyl, like the formulations produced at ASLONG's 10,000 square meter facility, maintains viscoelasticity up to 400°F.

- Safety: Butyl is odorless and does not off-gas toxic chemicals into your cabin.

- Adhesion: It remains sticky and flexible for decades, unlike asphalt which dries out and cracks.

Mistake 3: Aiming for 100% Coverage (The Law of Diminishing Returns)

You generally only need to cover 25% to 50% of a flat metal panel to effectively stop it from resonating. Applying sound deadener to every square inch of the car adds unnecessary weight and expense without providing a proportional reduction in decibels.

Work Smarter, Not Harder

The goal of sound deadening materials is to stop the panel from ringing, not to build a second wall. Once you have added enough mass to stop the resonance (the "ding" becomes a "thud"), adding more material yields diminishing returns.

Strategic Application:

- The Knock Test: Tap the panel with your knuckle. If it rings, apply material.

- Center Mass: Focus on the center of large, flat panels where vibration is most intense.

- Save Your Budget: Instead of 100% coverage with deadener, use that budget for sound deadening fiberglass insulation or Mass Loaded Vinyl (MLV) layers which actually block airborne noise.

Mistake 4: Leaving Air Bubbles and Failing to Use a Roller

You must use a heavy-duty roller to press the material firmly onto the metal, rolling from the center outwards to eliminate all air pockets. If you leave air bubbles, the material is decoupled from the metal, rendering the damping properties useless.

The Visual Check: "Waffling"

Simply pressing the material on with your hands is a rookie mistake. Your hands cannot generate enough pounds per square inch (PSI) to activate the pressure-sensitive adhesive fully.

- The Technique: Roll systematically. You want to see the texture of the foil backing flatten out or take on the shape of the curves underneath.

- The Consequence: Air gaps allow condensation to form between the mat and the car body. Over time, this trapped moisture can lead to hidden rust, rotting your vehicle from the inside out while the best sound deadening insulation hides the damage.

Mistake 5: Installing in Temperatures Below 60°F (15°C)

Do not install sound deadening material if the ambient temperature is below 60°F because the adhesive becomes brittle and loses its tack. Cold metal surfaces prevent the chemical bond from forming immediately, leading to immediate failure or poor long-term adhesion.

Managing the Environment

If you must install in winter, you need to artificially create the right conditions. Acoustic sound deadening panels are stiff when cold.

Expert Tips for Cold Weather:

- Heat the Material: Keep your mats inside the house until the moment you use them.

- Heat the Metal: Use a heat gun or hair dryer to warm the car panel before applying the mat.

- Pliability: The material should be soft and pliable. If it feels like stiff cardboard, it is too cold to install effectively.

Mistake 6: Confusing Sound Deadening with Sound Blocking

Sound deadening reduces vibration (structure-borne noise), whereas sound blocking materials prevent airborne noise (like traffic) from entering the cabin. Expecting a vibration mat to silence road noise completely is a fundamental misunderstanding of acoustics.

The Two-Stage Approach

To truly quiet a car, you need a system. This is often defined by the Sound Transmission Class (STC), a rating used to measure how well a barrier blocks sound (source: Wikipedia).

- Stage 1 (Deadening): Use Butyl mats to stop the metal from vibrating.

- Stage 2 (Blocking): Use Mass Loaded Vinyl (MLV) or sound deadening ceiling liners to block external noise waves.

For a deeper dive into the specific materials required for each stage, read our guide on A Comprehensive Comparison of Soundproofing Materials.

Mistake 7: Incorrect Layering Order (The "Sandwich" Error)

The correct order of application is always Metal -> Vibration Damper (CLD) -> Decoupler (Foam) -> Noise Barrier (MLV). Placing soft foam directly on the metal before the heavy deadener prevents the deadener from controlling the metal's vibration.

Building the Skyscraper

Think of your soundproofing as a construction project.

- Foundation: The automotive sound deadening material (CLD) goes directly on the painted metal.

- Air Gap: Closed Cell Foam (CCF) goes next. It acts as a decoupler, preventing the heavy MLV layer from rattling against the car body.

- Barrier: The Mass Loaded Vinyl goes on top.

If you mess up this order, you lose the efficiency of the system. For a look at the best materials for that middle layer, check out our article on the Top 10 Sound Insulation Foam Manufacturers for 2026.

Future-Proofing: Eco-Friendly Materials and 2026 Standards

Modern automotive standards are shifting towards lightweight, eco-friendly materials that reduce Volatile Organic Compounds (VOCs) in the cabin. As we approach 2026, the focus is on sustainable acoustics that do not compromise air quality.

ASLONG is at the forefront of this shift. Our research and development team focuses on creating sound deadening materials that meet strict European and North American environmental standards. We are moving beyond basic heavy rubber to advanced composites that offer high damping coefficients with significantly less weight, helping you save fuel while enjoying a quiet ride.

Conclusion

Achieving a luxury-quiet ride is within reach for any DIYer, but only if you respect the physics of sound. By avoiding these 7 common mistakes—skipping prep, using asphalt, over-covering, under-rolling, freezing the mats, confusing terms, and incorrect layering—you ensure that your investment in sound deadening material pays off for the life of the vehicle. Whether you are using ASLONG's premium butyl mats or other acoustic sound deadening panels, the technique is just as vital as the product.

Contact our team today to optimize your sound deadening strategy.

FAQ

Can I use roofing tape instead of sound deadening material?

No, roofing tape is asphalt-based. It can melt, smell toxic when heated, and offers poor damping performance compared to butyl. It is designed for outdoor static structures, not the high-heat, high-vibration environment of a car interior.

How much of the car do I really need to cover with sound deadener?

You do not need 100% coverage. 25% to 50% coverage on flat metal panels is sufficient to stop resonance. Adding more than this yields diminishing returns and adds unnecessary weight to your vehicle.

What is the difference between sound deadening and sound dampening?

They are often used interchangeably. Technically, "damping" refers to the energy dissipation process (converting vibration to heat), while "deadening" is the colloquial term for the result (a quieter panel). Both terms generally refer to the same category of products.

Does the thickness of the material (80 mil vs 50 mil) matter?

Yes, thickness generally correlates with mass. Thicker mats (80 mil+) absorb more vibrational energy, especially on vertical panels like doors or areas with high resonance. However, proper adhesion is more critical than thickness alone.

How do I remove old or melted sound deadening material?

Use dry ice to freeze and chip away asphalt-based material, as it becomes brittle when frozen. For butyl-based material, use a heat gun and a scraper, followed by a heavy solvent cleaner to remove the adhesive residue.

Is sound deadening material flammable?

High-quality automotive deadeners are fire-retardant and designed to withstand high temperatures. However, cheap substitutes, asphalt tapes, or DIY solutions like carpet padding may not be safe and can pose a fire risk.

What is the best temperature to install sound deadener?

Ideally, you should install these materials between 60°F and 80°F (15°C - 26°C). If you must install in colder conditions, use a heat gun to warm both the metal panel and the material to ensure a secure chemical bond.

Can I layer sound deadening material?

Layering CLD mats has diminishing returns and is not recommended. It is better to layer different types of materials (CLD + Foam + MLV) to address different frequencies rather than stacking the same vibration dampening mat twice.

OEM & Wholesale Car Sound Deadening Mat for All Vehicle Types | Automotive Noise Control Solutions

Soundproofing Foam for Car Heat Insulation | Reduce Noise & Block Heat

Bulk Sourcing ASTM E84 Class A Fire-Rated Mass Loaded Vinyl for Commercial Infrastructure: The 2026 Manufacturer Procurement Guide

Universal Car Sound Deadening Mat for Interior Modification and Upgrade

The Ultimate Guide to Soundproof Insulation: 2026 Trends and Expert Strategie

FAQs

Do ASLONG's products meet environmental protection standards?

Yes, all ASLONG products comply with ISO14001 environmental management system certification and global environmental protection standards. We use environmentally friendly materials and are committed to providing sustainable solutions to help customers achieve green development goals.

Does ASLONG provide after-sales service?

Yes, we provide a full range of after-sales services, including technical support, installation guidance, product maintenance and quality tracking, etc., to ensure that each project goes smoothly and continues to perform at its best.

What industries are the products provided by ASLONG suitable for?

ASLONG's products are suitable for multiple industries, including air conditioning and HVAC, construction and waterproofing, automobiles and transportation, home appliances and electronics, industrial equipment and machinery, etc. We provide customized solutions for each industry to meet different needs.

What specific functions can ASLONG's products provide?

Our products cover functions such as insulation, sound insulation, shock absorption, waterproofing and sealing, and are widely used in improving energy efficiency, reducing noise, controlling vibration, protecting equipment, etc., helping customers optimize engineering effects and improve user experience.

How to customize products that meet the needs of my industry?

You only need to contact our sales or technical team, we will conduct an in-depth analysis based on your industry needs and provide tailor-made products and solutions. We guarantee to provide you with efficient and accurate services to meet your personalized requirements.

Butyl Rubber Sound Damping Mat

ASLONG Butyl Rubber Sound Damping Mat for sale. Effectively reduces noise and vibrations. High-quality butyl rubber ensures superior performance and durability. Ideal for automotive, industrial, and home applications.

Mass Loaded Vinyl

ASLONG Mass Loaded Vinyl for sale. Reduce noise pollution effectively with our high-quality, mass-loaded vinyl. Ideal for soundproofing walls, floors, and more. Buy now and experience the difference!

Egg Crate Foam

ASLONG Egg Crate Foam for sale. Lightweight, breathable, and comfortable, our egg crate foam provides superior support and pressure relief. Perfect for mattresses, cushions, cars, construction industry, KTV, factories, etc.

NBR Foam

ASLONG NBR Foam: Wholesale NBR foam solutions for diverse applications. High-quality, durable, and competitively priced. Contact us today for bulk orders.

Multi layer Composite NBR foam

ASLONG's multi-layer composite NBR foam is your premium choice for superior cushioning and durability. Ideal for diverse applications, this high-quality NBR foam is available for sale now. Contact us for bulk orders.

Sound Absorbing White Cotton

Sound-absorbing white cotton Made from PP and PET fibres by melt-blowing, special processes are used to achieve density diversification, sound absorption and noise reduction, thermal insulation, moisture-proof and mold resistance.

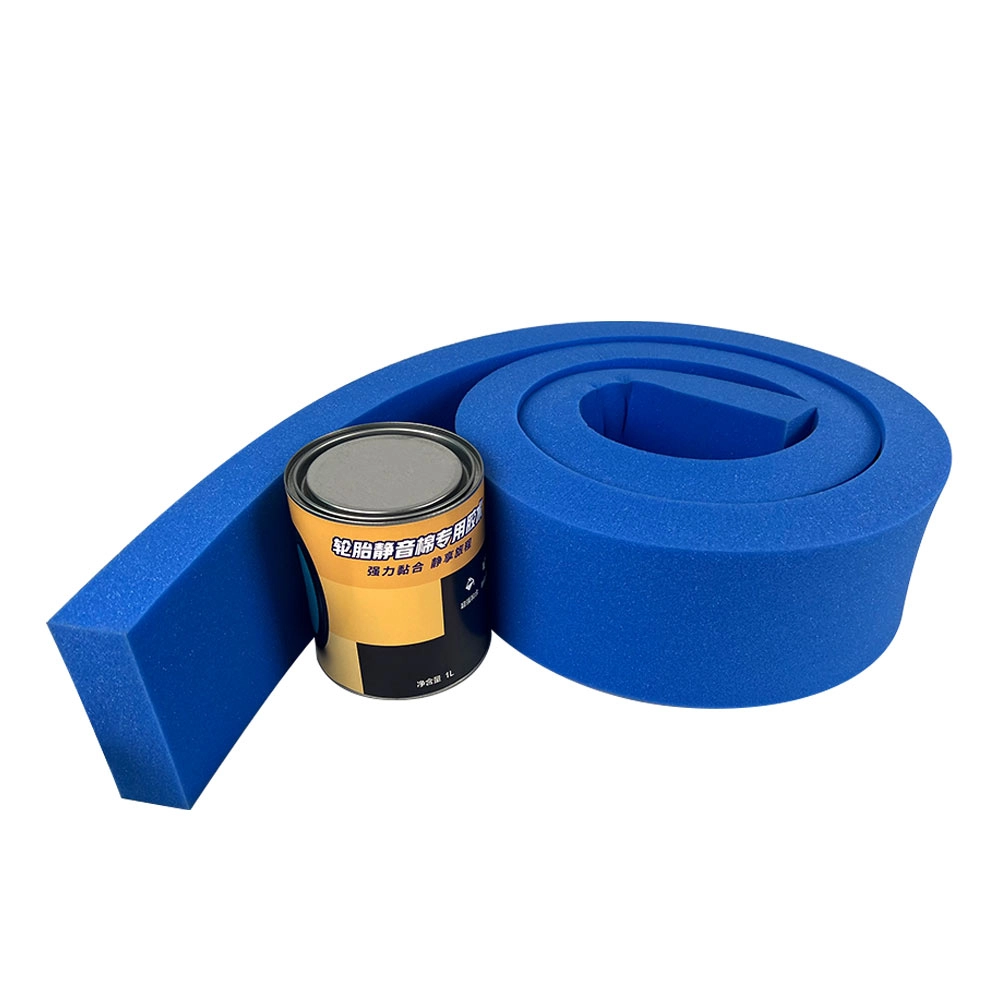

Puncture-Proof Soundproof Tire Foam, Self-Sealing Noise-Reducing Liner for Cars, Anti-Puncture Wheel Protection, Anti-Puncture Noise Reduction

Tire Silent Foam with Special Glue

ASLONG Tire Silent Foam with special glue effectively reduces tire noise. Improve your vehicle's ride comfort. Buy ASLONG Tire Silent Foam for sale now and experience the quiet difference.

Professional support at any time

Contact us for a free quote on our new soundproofing materials!

© 2026 ASLONG All Rights Reserved. Privacy Policy | Terms and Conditions | Sitemap

Whatsapp: +8613242879341

ASLONG Global

ASLONG

Aslong_global