Mass Loaded Vinyl for Industrial Noise Control

- Mass Loaded Vinyl for Industrial Noise Control

- What is mass loaded vinyl and why is it used in industrial noise control?

- How mass loaded vinyl works in industrial settings

- Key specifications to look for when buying mass loaded vinyl

- Typical MLV product comparisons (density and expected performance)

- Installation methods for industrial noise control with mass loaded vinyl

- Applications: walls, floors, ceilings, enclosures — where to buy mass loaded vinyl for industrial projects

- Performance comparison: mass loaded vinyl vs acoustic foam vs concrete

- Fire, health, and environmental considerations when selecting MLV

- Maintenance and longevity of mass loaded vinyl in industrial environments

- Cost considerations and calculating ROI when you buy mass loaded vinyl

- Why choose ASLONG Mass Loaded Vinyl for sale for industrial noise control?

- Brand advantages: what sets ASLONG Mass Loaded Vinyl apart

- Typical industrial case uses for ASLONG MLV

- FAQ — Frequently asked questions about Mass Loaded Vinyl (MLV) for industrial noise control

- Q: What decibel reduction can I expect when I buy mass loaded vinyl?

- Q: Can MLV control low-frequency industrial noise?

- Q: Is MLV easy to install around pipes and conduits?

- Q: Will MLV meet fire code requirements?

- Q: How do I maintain MLV in an industrial environment?

- Contact and product CTA

- Sources

Mass Loaded Vinyl for Industrial Noise Control

What is mass loaded vinyl and why is it used in industrial noise control?

Mass Loaded Vinyl (MLV) is a high-mass, flexible sound barrier made from vinyl loaded with heavy materials (commonly barium sulfate or calcium carbonate). It is designed to add mass to building elements—walls, floors, ceilings, and enclosures—to reduce the transmission of airborne noise. In industrial environments where machinery, compressors, pumps, and HVAC systems generate continuous or intermittent high-decibel noise, MLV is a practical solution to meet occupational safety standards, reduce community noise impact, and improve worker comfort. When applying MLV for industrial use, it helps to understand comparing Mass Loaded Vinyl grades and quality, so you can select the most effective material for your noise control needs.

How mass loaded vinyl works in industrial settings

Mass Loaded Vinyl reduces sound primarily through the mass law: increasing the mass of a barrier lowers the amount of sound energy transmitted through it, particularly for mid- to high-frequency airborne noise. MLV's flexibility allows it to be applied directly to existing structures or wrapped around equipment and ductwork, where rigid barriers may be impractical. In an industrial installation, MLV is often combined with resilient channels, absorptive layers, or enclosure design to control both airborne and structure-borne noise.

Key specifications to look for when buying mass loaded vinyl

When specifying Mass Loaded Vinyl for industrial noise control, focus on mass per unit area (commonly given in lb/ft2 or kg/m2), thickness, tensile strength for handling, fire performance (flame spread and smoke development ratings), and environmental resistance (oil, chemical, UV if exposed). Manufacturer datasheets will also provide expected performance improvements (e.g., STC/Rw increments) and recommended installation details.

Typical MLV product comparisons (density and expected performance)

The following table summarizes common MLV product weights and approximate performance expectations. Actual results depend on system construction and frequencies; use lab-tested data from manufacturers for design decisions.

| MLV Mass (typical) | Mass per Area | Common Use | Approx. STC Improvement* |

|---|---|---|---|

| 0.5 lb/ft² | ~2.4 kg/m² | Light partition upgrades, duct wrap | +3 to +5 |

| 1.0 lb/ft² | ~4.9 kg/m² | Standard wall/floor upgrades, equipment enclosures | +5 to +8 |

| 2.0 lb/ft² | ~9.8 kg/m² | High-performance barriers, heavy equipment rooms | +8 to +12 |

*Approximate STC improvement over a lightweight partition; actual results vary by construction and frequency. See manufacturer/lab data for precise values.

Installation methods for industrial noise control with mass loaded vinyl

Proper installation is essential to achieve predicted noise reduction. Common methods include:

- Direct fasten to walls/ceilings: MLV can be adhered or mechanically fastened to existing surfaces; ensure continuous coverage and sealed seams.

- Double-layer assemblies: MLV paired with plywood, drywall, or metal sheeting increases mass and improves low-frequency performance.

- Resilient mounting: Combining MLV with resilient channels or decoupling mounts reduces structure-borne transmission.

- Equipment enclosures: Lining the inside of machine enclosures with MLV reduces airborne noise escaping through panels and openings.

- Duct and pipeline wrap: MLV reduces airborne noise traveling through ducts and piping cavities, and helps attenuate secondary radiation.

For industrial installations, seal all edges and penetrations (conduits, bolts, inspection doors) with acoustic sealant; even small gaps dramatically reduce barrier effectiveness.

Applications: walls, floors, ceilings, enclosures — where to buy mass loaded vinyl for industrial projects

Mass Loaded Vinyl is used across many industrial applications: plant partitions, control rooms, pump and compressor rooms, acoustic enclosures, loud machinery cabinets, HVAC and fan housings, and temporary noise barriers during maintenance. When sourcing MLV, specify industrial-grade products with appropriate mass, tear strength, and—where required—fire-rated formulations. ASLONG Mass Loaded Vinyl for sale is designed to meet industry needs for these applications.

Performance comparison: mass loaded vinyl vs acoustic foam vs concrete

Understanding strengths and limits helps choose the right approach. Acoustic foam primarily absorbs high-frequency energy but lacks mass, so it does little against airborne transmission. Concrete provides high mass but is costly and impractical for retrofits. MLV offers a balance: high mass in a thin, flexible form that adapts to existing structures.

| Material | Primary Benefit | Best for | Limitations |

|---|---|---|---|

| Mass Loaded Vinyl (MLV) | Adds mass; blocks airborne noise | Retrofits, enclosures, ducts | Less effective for low-frequency if used alone; seams must be sealed |

| Acoustic Foam | Absorbs reverberation and high frequencies | Interior reverberation control | Minimal sound transmission reduction |

| Concrete / Masonry | High mass; excellent transmission loss | New construction, permanent barriers | Costly, heavy, impractical for retrofits |

Fire, health, and environmental considerations when selecting MLV

For industrial use, fire performance is crucial—check product flame-spread and smoke development ratings (or UL classifications) for compliance with local codes. Many manufacturers add fire retardants to MLV; confirm that the specific formulation meets your facility's code and insurance requirements. Also evaluate chemical resistance if MLV will be exposed to oils, solvents, or harsh cleaners, and request safety data sheets (SDS) for handling and disposal guidance.

Maintenance and longevity of mass loaded vinyl in industrial environments

MLV is durable when installed correctly: it's resistant to tearing, and if protected from sharp edges and prolonged UV exposure, it can last many years. Regular inspections should focus on seams, fasteners, and penetrations. Replace or repair sections with visible damage to maintain continuous barrier performance. For washdown areas, ensure the selected MLV formulation and seam treatments tolerate the cleaning agents used.

Cost considerations and calculating ROI when you buy mass loaded vinyl

Upfront material and labor costs vary with product weight, area coverage, and complexity of installation. When evaluating ROI, consider:

- Regulatory compliance (reduced risk of fines for exceeding occupational exposure limits)

- Improved worker productivity and reduced absenteeism from excessive noise

- Lower vibration-related maintenance costs (when MLV is used with decoupling systems)

- Community noise complaints avoidance and faster permitting for expansions

Ask suppliers for sample calculations and references for similar industrial projects to estimate payback timelines.

Why choose ASLONG Mass Loaded Vinyl for sale for industrial noise control?

ASLONG offers industrial-grade Mass Loaded Vinyl designed for reliable noise reduction in demanding environments. Our MLV products balance mass, flexibility, and durability to suit retrofits, enclosures, and permanent installations. ASLONG products come with technical datasheets, recommended installation practices, and access to technical support to help design effective noise-control systems.

ASLONG Mass Loaded Vinyl for sale. Reduce noise pollution effectively with our high-quality, mass-loaded vinyl. Ideal for soundproofing walls, floors, and more. Buy now and experience the difference!

Brand advantages: what sets ASLONG Mass Loaded Vinyl apart

- Industrial formulations: Available in multiple mass-per-area options to match performance needs and budget.

- Durability: Reinforced options reduce tearing and extend service life in factory environments.

- Technical support: Guidance on system design, attachment methods, and compliance considerations.

- Compliance-minded: Fire-retardant options and available documentation to support code approvals.

- Supply and logistics: Regular stock and reliable delivery for large industrial projects.

Typical industrial case uses for ASLONG MLV

Examples where ASLONG MLV performs well include compressor rooms, HVAC fan rooms, generator enclosures, packaging lines, printing presses, and any application where thin, effective mass barriers are needed without heavy construction. Our team can help size product and propose assemblies combining MLV with absorptive layers or resilient mounts for best results.

FAQ — Frequently asked questions about Mass Loaded Vinyl (MLV) for industrial noise control

Q: What decibel reduction can I expect when I buy mass loaded vinyl?

A: Typical airborne noise reduction ranges depend on the existing construction and MLV mass. Single-layer 1.0 lb/ft² MLV used on a lightweight partition can often yield 5–8 dB improvement in perceived transmission in practical conditions; combining MLV with additional mass and decoupling techniques increases effectiveness. For precise predictions, request lab-tested assemblies or on-site measurements.

Q: Can MLV control low-frequency industrial noise?

A: MLV is effective on mid- and high-frequency airborne noise. Low-frequency noise (<250 Hz) is harder to control and often requires greater mass, thicker multi-layer assemblies, or hybrid approaches (mass + decoupling + damping). For low-frequency issues, consult an acoustical engineer to design a targeted solution.

Q: Is MLV easy to install around pipes and conduits?

A: Yes—MLV's flexibility makes it suitable for wrapping around pipes and ducts. Maintain complete coverage and seal all seams and service penetrations with acoustic sealant or approved tapes to preserve barrier performance.

Q: Will MLV meet fire code requirements?

A: Some MLV formulations are treated for improved flame resistance and come with test data or UL classifications. Always verify the product's fire performance against local code requirements and request relevant test reports from your supplier.

Q: How do I maintain MLV in an industrial environment?

A: Inspect seams and fasteners periodically, protect exposed edges from mechanical damage, and replace damaged sections. Use compatible cleaners if required and consult the SDS for handling and disposal guidance.

Contact and product CTA

Ready to reduce noise in your facility? Contact our technical sales team to request ASLONG Mass Loaded Vinyl product data sheets, pricing, and installation guidance. Visit the product page to view available weights and order options, or contact us for a site assessment and quotation.

Contact us: Request a quote or speak with an acoustic specialist to determine the right ASLONG Mass Loaded Vinyl solution for your industrial project.

Sources

- OSHA — Occupational Noise Exposure: https://www.osha.gov/noise

- EPA — Noise: https://www.epa.gov/noise

- Acoustical Surfaces — Mass Loaded Vinyl product and performance overview: https://www.acousticalsurfaces.com/soundproofing/mass-loaded-vinyl.htm

- Green Glue Company — What is Mass Loaded Vinyl?: https://www.greengluecompany.com/soundproofing-resources/what-is-mass-loaded-vinyl/

- Soundproofing Company — Mass Loaded Vinyl guide and applications: https://www.soundproofingcompany.com/mass-loaded-vinyl/

- ASTM E90 — Standard Test Method for Laboratory Measurement of Airborne Sound Transmission Loss of Building Partitions and Elements: https://www.astm.org/Standards/E90.htm

Vibration Damping Materials for Vehicle Noise Control 2026

How to manufacturing aluminium foil tape waterproof

Understanding STC Ratings with Mass Loaded Vinyl

The B2B Buyer’s Guide to soundproof materials for vehicles

FAQs

What specific functions can ASLONG's products provide?

Our products cover functions such as insulation, sound insulation, shock absorption, waterproofing and sealing, and are widely used in improving energy efficiency, reducing noise, controlling vibration, protecting equipment, etc., helping customers optimize engineering effects and improve user experience.

Does ASLONG provide after-sales service?

Yes, we provide a full range of after-sales services, including technical support, installation guidance, product maintenance and quality tracking, etc., to ensure that each project goes smoothly and continues to perform at its best.

What industries are the products provided by ASLONG suitable for?

ASLONG's products are suitable for multiple industries, including air conditioning and HVAC, construction and waterproofing, automobiles and transportation, home appliances and electronics, industrial equipment and machinery, etc. We provide customized solutions for each industry to meet different needs.

How to customize products that meet the needs of my industry?

You only need to contact our sales or technical team, we will conduct an in-depth analysis based on your industry needs and provide tailor-made products and solutions. We guarantee to provide you with efficient and accurate services to meet your personalized requirements.

Do ASLONG's products meet environmental protection standards?

Yes, all ASLONG products comply with ISO14001 environmental management system certification and global environmental protection standards. We use environmentally friendly materials and are committed to providing sustainable solutions to help customers achieve green development goals.

Butyl Rubber Sound Damping Mat

ASLONG Butyl Rubber Sound Damping Mat for sale. Effectively reduces noise and vibrations. High-quality butyl rubber ensures superior performance and durability. Ideal for automotive, industrial, and home applications.

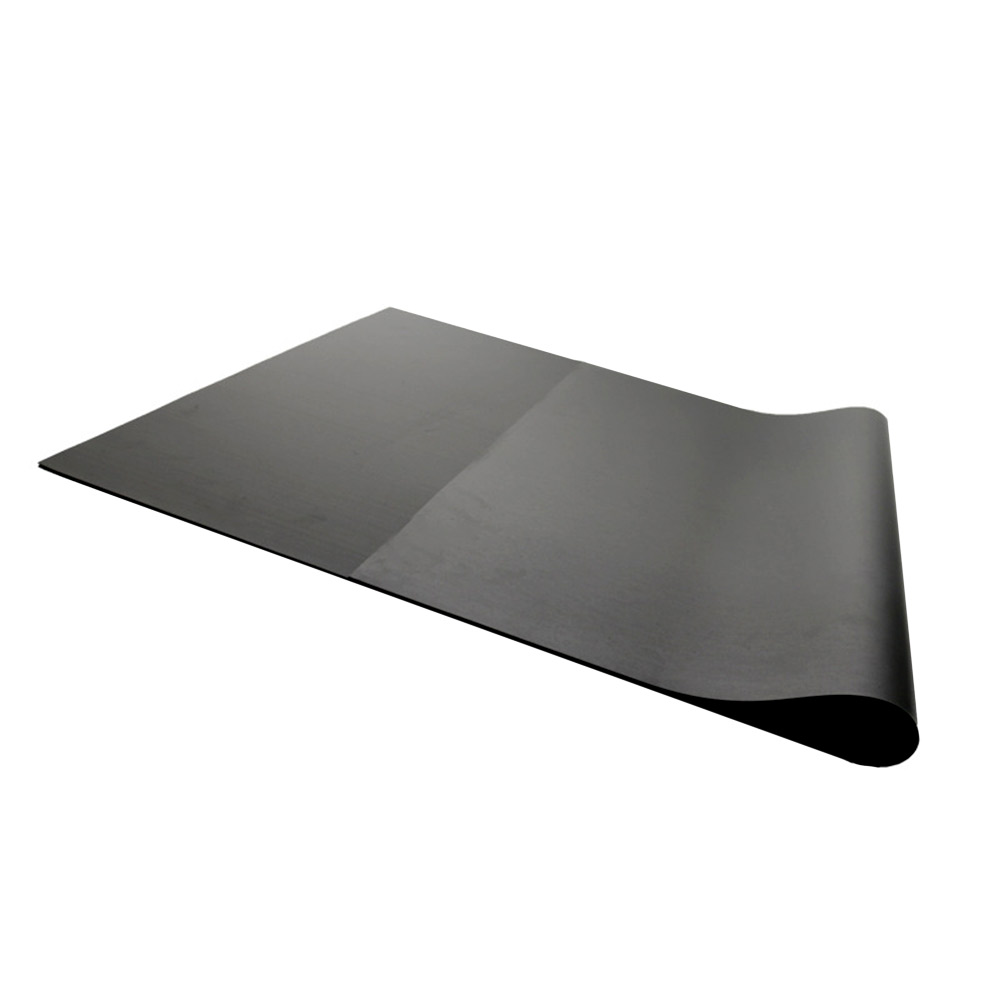

Mass Loaded Vinyl

ASLONG Mass Loaded Vinyl for sale. Reduce noise pollution effectively with our high-quality, mass-loaded vinyl. Ideal for soundproofing walls, floors, and more. Buy now and experience the difference!

Egg Crate Foam

ASLONG Egg Crate Foam for sale. Lightweight, breathable, and comfortable, our egg crate foam provides superior support and pressure relief. Perfect for mattresses, cushions, cars, construction industry, KTV, factories, etc.

NBR Foam

ASLONG NBR Foam: Wholesale NBR foam solutions for diverse applications. High-quality, durable, and competitively priced. Contact us today for bulk orders.

Professional support at any time

If you have any comments or good suggestions, please leave us a message; later our professional staff will contact you as soon as possible.

© 2026 ASLONG All Rights Reserved. Privacy Policy | Terms and Conditions | Sitemap

Whatsapp: +8613242879341

ASLONG Global

ASLONG

Aslong_global