What is the best method to ensure sound damping sheets adhere properly to textured or uneven surfaces? | ASLONG Guide

- What is the Best Method to Ensure Sound Damping Sheets Adhere Properly to Textured or Uneven Surfaces?

- Ensuring Proper Adhesion of Sound Damping Sheets on Uneven Surfaces

- Surface Preparation: Key to Long-Lasting Adherence

- Mechanical or Manual Smoothing

- Selection of Adhesive

- Application Technique

- Sheet Flexibility

- Environmental Conditions

- Verification and Quality Control

- Quick Facts

- Sources and Industry Standards

- SEO Meta Elements

What is the Best Method to Ensure Sound Damping Sheets Adhere Properly to Textured or Uneven Surfaces?

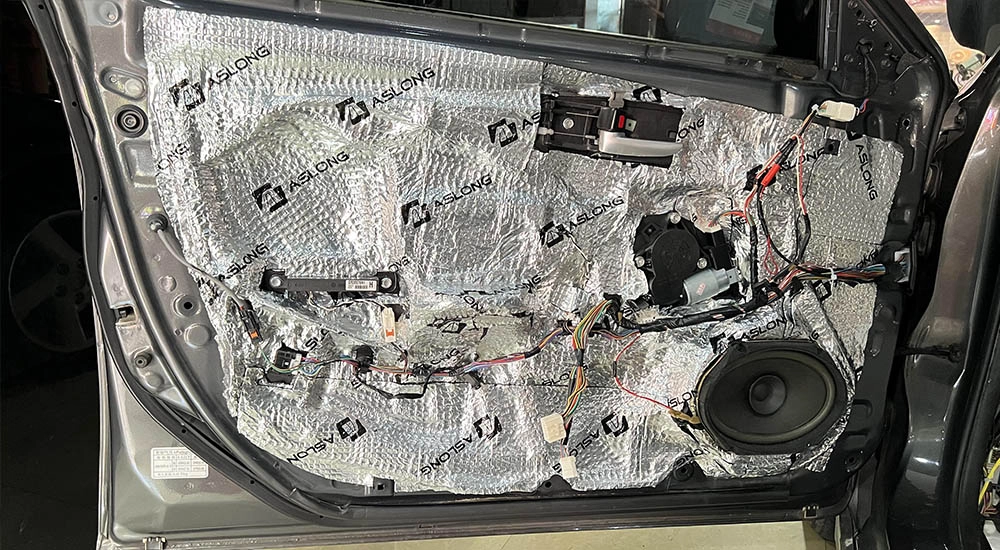

Professionals in the sound insulation materials industry often face the challenge of achieving optimal adhesion for sound damping sheets on textured or uneven surfaces. This article discusses industry-proven techniques using expert knowledge, highlighting best practices, material compatibility, and surface preparation for maximum adhesion results.

Ensuring Proper Adhesion of Sound Damping Sheets on Uneven Surfaces

Surface Preparation: Key to Long-Lasting Adherence

- Thorough Cleaning:

- Remove dust, oil, and debris using industrial cleaners.

- Reference: (https://www.ashrae.org/)

- De-greasing:

- Use isopropyl alcohol or dedicated surface prep wipes for better adhesive grip.

- Drying:

- Ensure complete dryness before application—moisture undermines adhesion.

Mechanical or Manual Smoothing

- Filling and Leveling:

- Apply a thin layer of compatible filler to bridge deep textures or gaps.

- Use acoustic putty or silicone-based fillers for best results.

- Sanding:

- Lightly sand high spots to create a more uniform base.

- Avoid over-sanding to preserve substrate integrity.

Selection of Adhesive

- High-Tack Industrial Adhesives:

- Use butyl rubber-based or synthetic polymer adhesives for strong bonding to irregular surfaces.

- Products should comply with standards such as ASTM D1000 (Standard Test Methods for Pressure-Sensitive Adhesive-Coated Tapes).

- Adhesive Promoters or Primers:

- Apply primer for improved initial tack and long-term hold on porous or rough substrates.

Application Technique

- Hand Roller/Mechanical Pressure:

- Use a heavy-duty hand roller to press sound damping sheets firmly, targeting valleys and peaks.

- Heat Activation:

- Some adhesives activate with gentle heat (generally 40–50°C)—use a heat gun to soften and ensure a secure bond, especially with butyl-based materials.

- Overlap and Sealing:

- Overlap edges and seal joints with acoustic tape to avoid air gaps.

Sheet Flexibility

- Flexible Sheet Material:

- Opt for damping sheets with high conformability specifications (see manufacturer’s data sheets), ideal for uneven or contoured surfaces.

- Thickness Consideration:

- Thinner sheets adapt better to roughness, while thicker sheets may require more force or dual adhesives.

Environmental Conditions

- Ideal Temperature and Humidity:

- Apply at temperatures recommended by the adhesive manufacturer (usually 15–30°C) for best results.

- Reference: (https://www.sandv.com/)

Verification and Quality Control

- Adhesion Test:

- Conduct a peel test post-application to verify secure attachment.

- Visual Inspection:

- Check for air pockets and incomplete contact; reapply pressure as necessary.

Quick Facts

- Cleaning and priming are critical before applying sound damping sheets.

- Using rollers and heat activation enhances bonding to textured or uneven surfaces.

- Select adhesives per substrate type and environmental conditions.

- Testing and inspection ensure professional, durable installations.

Sources and Industry Standards

- (https://www.ashrae.org/)

- (https://www.astm.org/d1000-10.html)

- (https://www.sandv.com/)

SEO Meta Elements

The 10 Best Sound Absorbing Materials (2026): The Ultimate Buyer’s Guide to Professional Noise Control

OEM & Wholesale Car Sound Deadening Mat for All Vehicle Types | Automotive Noise Control Solutions

Soundproofing Foam for Car Heat Insulation | Reduce Noise & Block Heat

![7-Costly-Mistakes-to-Avoid-When-Installing-Sound-Deadening-Material-[Expert-Tips] 7 Costly Mistakes to Avoid When Installing Sound Deadening Material [Expert Tips]](https://static.gooecloud.com/upload/img/GY038097216927/7-costly-mistakes-to-avoid-when-installing-sound-deadening-material-expert-tips.png?x-oss-process=image/format,webp/quality,Q_100)

7 Costly Mistakes to Avoid When Installing Sound Deadening Material [Expert Tips]

Bulk Sourcing ASTM E84 Class A Fire-Rated Mass Loaded Vinyl for Commercial Infrastructure: The 2026 Manufacturer Procurement Guide

FAQs

Do ASLONG's products meet environmental protection standards?

Yes, all ASLONG products comply with ISO14001 environmental management system certification and global environmental protection standards. We use environmentally friendly materials and are committed to providing sustainable solutions to help customers achieve green development goals.

What industries are the products provided by ASLONG suitable for?

ASLONG's products are suitable for multiple industries, including air conditioning and HVAC, construction and waterproofing, automobiles and transportation, home appliances and electronics, industrial equipment and machinery, etc. We provide customized solutions for each industry to meet different needs.

Does ASLONG provide after-sales service?

Yes, we provide a full range of after-sales services, including technical support, installation guidance, product maintenance and quality tracking, etc., to ensure that each project goes smoothly and continues to perform at its best.

What specific functions can ASLONG's products provide?

Our products cover functions such as insulation, sound insulation, shock absorption, waterproofing and sealing, and are widely used in improving energy efficiency, reducing noise, controlling vibration, protecting equipment, etc., helping customers optimize engineering effects and improve user experience.

How to customize products that meet the needs of my industry?

You only need to contact our sales or technical team, we will conduct an in-depth analysis based on your industry needs and provide tailor-made products and solutions. We guarantee to provide you with efficient and accurate services to meet your personalized requirements.

Butyl Rubber Sound Damping Mat

ASLONG Butyl Rubber Sound Damping Mat for sale. Effectively reduces noise and vibrations. High-quality butyl rubber ensures superior performance and durability. Ideal for automotive, industrial, and home applications.

Mass Loaded Vinyl

ASLONG Mass Loaded Vinyl for sale. Reduce noise pollution effectively with our high-quality, mass-loaded vinyl. Ideal for soundproofing walls, floors, and more. Buy now and experience the difference!

Egg Crate Foam

ASLONG Egg Crate Foam for sale. Lightweight, breathable, and comfortable, our egg crate foam provides superior support and pressure relief. Perfect for mattresses, cushions, cars, construction industry, KTV, factories, etc.

NBR Foam

ASLONG NBR Foam: Wholesale NBR foam solutions for diverse applications. High-quality, durable, and competitively priced. Contact us today for bulk orders.

Multi layer Composite NBR foam

ASLONG's multi-layer composite NBR foam is your premium choice for superior cushioning and durability. Ideal for diverse applications, this high-quality NBR foam is available for sale now. Contact us for bulk orders.

Sound Absorbing White Cotton

Sound-absorbing white cotton Made from PP and PET fibres by melt-blowing, special processes are used to achieve density diversification, sound absorption and noise reduction, thermal insulation, moisture-proof and mold resistance.

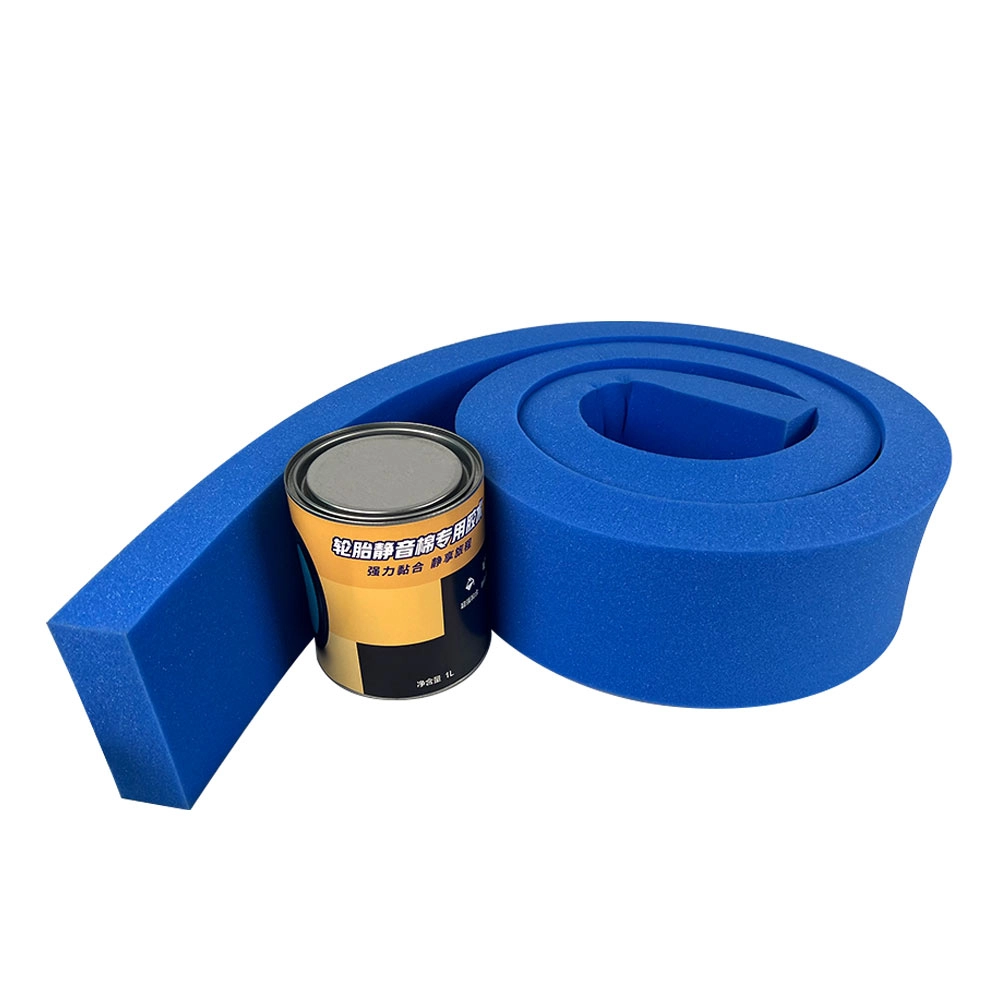

Puncture-Proof Soundproof Tire Foam, Self-Sealing Noise-Reducing Liner for Cars, Anti-Puncture Wheel Protection, Anti-Puncture Noise Reduction

Tire Silent Foam with Special Glue

ASLONG Tire Silent Foam with special glue effectively reduces tire noise. Improve your vehicle's ride comfort. Buy ASLONG Tire Silent Foam for sale now and experience the quiet difference.

Professional support at any time

Contact us for a free quote on our new soundproofing materials!

© 2026 ASLONG All Rights Reserved. Privacy Policy | Terms and Conditions | Sitemap

Whatsapp: +8613242879341

ASLONG Global

ASLONG

Aslong_global