Testing Standards and Certification for Car Sound Damping Sheets

- Testing Standards and Certification for Car Sound Damping Sheets

- Why testing and certification matter for car sound damping material

- Product highlight: Car Sound Damping Sheet

- Categories of tests for car sound damping material

- Key acoustic measurements for sound damping sheets (what to look for)

- Common standards and organisations involved

- Typical laboratory tests and what they measure

- Practical interpretation: what results mean for installers and buyers

- Certifications and labels to request from manufacturers

- How manufacturers validate products: a typical development and approval path

- Case study-style example (how a sheet is evaluated for a sedan rear floor)

- Comparing products: what specifications matter most

- Brand advantages: why choose ASLONG Car Sound Damping Sheet

- Selecting the right supplier and interpreting documentation

- Installation and quality control tips for installers

- FAQ — Common questions about testing and certification for car sound damping sheets

- Contact us / View product

- Authoritative references and further reading

Testing Standards and Certification for Car Sound Damping Sheets

Why testing and certification matter for car sound damping material

Car sound damping material plays a direct role in vehicle comfort, perceived quality and long-term durability. Proper testing and certification ensure a product like the Car Sound Damping Sheet performs as promised — reducing road noise and vibration without causing safety, environmental, or compatibility problems. For vehicle manufacturers, installers and consumers, recognised tests and certifications translate into predictable performance, regulatory compliance and peace of mind. Once compliance is confirmed, procurement leaders should assess continuity and resilience through a deeper look at supply chain risks and sourcing for car sound damping material.

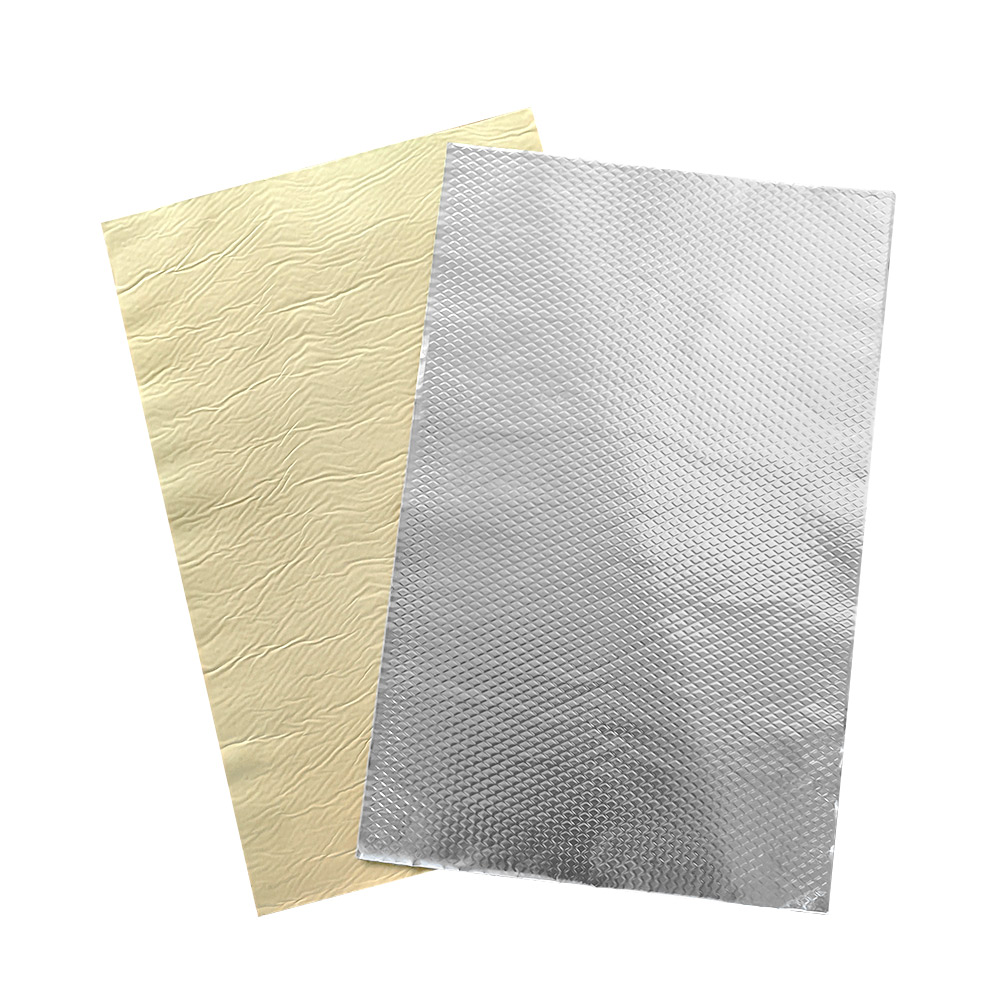

Product highlight: Car Sound Damping Sheet

Discover the ASLONG Car Sound Damping Sheet—High Quality sound damping material designed to reduce road noise and vibration. Improve your driving comfort with this easy-to-install, durable car sound damping sheet for superior sound insulation.

Categories of tests for car sound damping material

Testing can be grouped into a few essential categories. Each answers a different question about the product:

- Acoustic performance: How much noise or vibration does the material reduce in lab and in-vehicle conditions?

- Physical and mechanical: Adhesion, density, mass per unit area, thickness, and dimensional stability.

- Environmental and durability: Temperature cycling, humidity exposure, UV and long-term aging.

- Safety and regulatory: Flammability, VOC emissions, hazardous substances (REACH/RoHS), and automotive interior safety standards.

- Quality systems and traceability: Production quality standards such as ISO 9001 or IATF 16949 for automotive suppliers.

Key acoustic measurements for sound damping sheets (what to look for)

Acoustic testing shows how effective a damping sheet is at reducing noise. Typical measurements include:

- Transmission Loss (TL) or Sound Transmission Class (STC): Measures reduction of airborne noise through a structure or assembly.

- Insertion Loss (IL): Measured in a real or simulated vehicle environment, IL quantifies how much noise is reduced when material is added.

- Damping Loss Factor and Dynamic Stiffness: Laboratory measurements that predict how well a material reduces vibration when applied to panels.

- In-vehicle NVH tests: Road and chassis dynamometer tests capturing real-world noise and vibration under defined operating conditions.

Common standards and organisations involved

Different regions and industries rely on widely accepted organisations for testing protocols. Key organisations include:

- ISO (International Organization for Standardization) — provides general acoustic and test-method standards used globally.

- ASTM International — offers standardized test methods for materials, emissions, and acoustic properties.

- SAE International — automotive-focused standards and recommended practices for NVH testing.

- UNECE and national regulators — regional vehicle regulations can affect material approval and signalling compliance needs.

- National authorities (e.g., NHTSA/FMVSS in the United States) — set vehicle interior flammability standards like FMVSS 302.

Typical laboratory tests and what they measure

Below is a concise table comparing common test types, their purpose, typical referenced standards (examples), and what OEMs or installers should expect to see reported.

| Test | Purpose | Typical standard or method (examples) | What to check in reports |

|---|---|---|---|

| Transmission Loss / Sound Transmission | Measures airborne noise reduction through panels or assemblies | ISO acoustic test methods, ASTM E90 (building partition example) | Frequency-dependent TL curves, overall reduction in dB across 100–4000 Hz |

| Insertion Loss (In-vehicle or rig) | Real-world reduction when material is added | SAE J-standard test setups or manufacturer-specific NVH protocols | Before/after spectra, weighted overall dB reduction in targeted bands |

| Damping loss factor / Dynamic stiffness | Predicts vibrational energy dissipation on panels | ISO vibrational test methods, laboratory modal analysis | Frequency-dependent loss factor, dynamic stiffness in MN/m |

| Flammability | Ensures interior safety under ignition scenarios | FMVSS 302 (US), analogous regional standards | Burn rate, compliance pass/fail |

| VOC emissions | Measures off-gassing that affects cabin air quality | Chamber tests (examples: ISO small chamber methods, ASTM D5116) | TVOC and specific compound concentrations in µg/m3 |

| Adhesion / Peel strength | Confirms product will stay attached under conditions | ASTM adhesion methods or automotive supplier test procedures | Initial peel strength, adhesive failure mode, adhesion after aging |

| Durability (thermal cycling, humidity) | Checks long-term performance under real-world climates | ISO environmental testing procedures | Post-test acoustic and adhesion performance, physical changes |

Practical interpretation: what results mean for installers and buyers

Test reports can contain technical charts and numbers. For non-specialists, here are practical takeaways:

- Look for frequency-dependent acoustic reduction: Vehicle noise is often concentrated in low-to-mid frequencies (50–1000 Hz). Materials that show gains in these bands are most valuable.

- Adhesion and durability matter more than initial acoustic numbers. A product that falls off after months delivers no lasting benefit.

- Flammability and VOC compliance are non-negotiable for safe cabin use—always ask for certificates or lab reports.

- If a product is intended for OEM use, expect supplier-level quality system evidence (ISO 9001 / IATF 16949) and batch traceability.

Certifications and labels to request from manufacturers

When evaluating car sound damping material, ask the supplier for:

- Independent acoustic test reports showing insertion loss and laboratory damping metrics.

- Flammability test certificates (for example, FMVSS 302 or an equivalent regional standard).

- VOC emission and chemical compliance data (e.g., chamber test results; REACH and RoHS declarations where applicable).

- Material safety data sheet (MSDS/SDS) and physical property datasheet.

- Quality system certificates (ISO 9001, and for automotive-grade supply, IATF 16949 where relevant).

How manufacturers validate products: a typical development and approval path

Manufacturers of Car Sound Damping Sheet typically follow these stages to validate products for automotive use:

- Material selection and bench testing for density, adhesion and damping loss factor.

- Laboratory acoustic testing (panel tests, transmission loss, loss factor).

- Prototype vehicle or rig tests measuring insertion loss and NVH improvements under representative road conditions.

- Environmental aging (thermal cycling, humidity, UV) followed by re-testing to confirm retention of properties.

- Regulatory and safety testing for flammability and VOCs, plus substance compliance checks.

- Quality system audits and batch release testing for production control.

Case study-style example (how a sheet is evaluated for a sedan rear floor)

Imagine evaluating a Car Sound Damping Sheet for installation on a compact sedan rear floor:

- Step 1: Lab modal tests on the rear floor panel quantify natural frequencies and indicate which bands produce most vibration.

- Step 2: Candidate damping sheet is applied to test coupons and lab-damping tests produce loss-factor improvements in the 80–400 Hz band.

- Step 3: Vehicle-level insertion loss tests show a 2–4 dB reduction in road/tyre noise bands — audible and measurable improvement.

- Step 4: Adhesion and thermal aging confirm the material holds at operating temperatures and after 2,000 hours equivalent aging.

- Step 5: VOC and flammability tests confirm cabin safety and regulatory compliance; product is cleared for production or aftermarket sale.

Comparing products: what specifications matter most

When comparing competing car sound damping material, prioritize these measurable specs:

- Mass per unit area: Heavier sheets usually provide more TL but may increase vehicle weight.

- Dynamic stiffness / loss factor: Indicates vibro-acoustic performance per unit mass.

- Adhesion / peel strength: Ensures longevity after installation and thermal stress.

- VOC levels and flammability rating: Safety and cabin air quality compliance.

- Ease of installation: Peel-and-stick, conformability, cutability and how well it fits complex shapes.

Brand advantages: why choose ASLONG Car Sound Damping Sheet

ASLONG focuses on delivering an automotive-grade Car Sound Damping Sheet that balances acoustic performance, durability and compliance. Key advantages:

- Designed for targeted NVH reductions in the low-to-mid frequency bands typical of road and tyre noise.

- Easy-to-install peel-and-stick format with strong initial and aged adhesion, suitable for common vehicle panels.

- Manufactured under quality processes that support traceability and batch testing for consistent performance.

- Tested for flammability and low VOC emissions to prioritise occupant safety and comfort.

- Durable construction that retains properties after environmental cycling and vehicle-relevant stresses.

Selecting the right supplier and interpreting documentation

When evaluating a supplier:

- Ask for full lab reports, not just summary claims. Look for measurement methods, test conditions and raw data plots.

- Confirm whether acoustic tests were performed by independent accredited labs (NVLAP, ISO/IEC 17025 accredited labs are preferred).

- Compare like-for-like: ensure test setups and panel/vehicle conditions are similar when comparing insertion loss numbers.

- Request sample materials for fitment trials on the target vehicle panels to check conformability and adhesion.

Installation and quality control tips for installers

Proper installation preserves the tested performance:

- Clean bonding surfaces thoroughly (no oils, dust or paint residues) and follow manufacturer surface prep recommendations.

- Apply consistent pressure during adhesive cure to eliminate trapped air and ensure full contact.

- Avoid excessive stretching of sheets on complex contours—use cut patterns where needed to maintain material integrity.

- Inspect and document adhesion after initial installation and at recommended intervals for fleet or commercial vehicles.

FAQ — Common questions about testing and certification for car sound damping sheets

Q1: Do I need a certification to sell damping sheets for aftermarket car use?

A1: For general aftermarket sales to consumers, there is no single global acoustic certification required. However, you should provide flammability and VOC test reports and ensure the product complies with regional chemical restrictions (e.g., REACH in EU). For OEM supply, additional supplier-level quality certifications and specific vehicle approval tests are usually necessary.

Q2: How much noise reduction can I expect after installing a damping sheet?

A2: Measurable improvements are typically in the range of 1–5 dB overall, depending on vehicle, installation coverage and frequency band. Improvements in subjective cabin comfort can feel greater because damping reduces resonant vibration and tonal noise.

Q3: How to verify that a lab report is reliable?

A3: Check whether the testing laboratory is accredited (ISO/IEC 17025), review full test conditions, and ensure raw frequency data or plots are provided. Independent third-party lab testing is more reliable than manufacturer-only internal reports.

Q4: Which tests are most important for health and safety?

A4: Flammability tests (e.g., FMVSS 302 or equivalent), VOC emissions chamber tests, and confirmation of absence of restricted substances under regulations like REACH and RoHS.

Q5: Can lighter materials perform as well as heavier ones?

A5: Modern engineered damping materials can deliver strong damping per unit mass (high loss factor), but there is a trade-off between mass, absorption and structural damping. Evaluate dynamic stiffness and loss-factor metrics, not just mass.

Contact us / View product

If you want certified performance and reliable installation support, contact our team to request full test reports or samples of the ASLONG Car Sound Damping Sheet. For direct product details and purchasing, visit our product page or reach out to customer service at .

Authoritative references and further reading

Below are reputable organisations and pages for standards and test method information:

- International Organization for Standardization (ISO) — https://www.iso.org/

- ASTM International — https://www.astm.org/

- SAE International — https://www.sae.org/

- UNECE — https://unece.org/

- U.S. National Highway Traffic Safety Administration (FMVSS information) — https://www.nhtsa.gov/

- European Chemicals Agency (REACH) — https://echa.europa.eu/

- IATF Global Oversight (IATF 16949 automotive quality) — https://www.iatfglobaloversight.org/

Mass Loaded Vinyl: Myths vs Facts

Installation Best Practices for Butyl Rubber Sound Damping Mat

What is Car Sound Insulation

Mass Loaded Vinyl for Music Studios and Recording Rooms

FAQs

How to customize products that meet the needs of my industry?

You only need to contact our sales or technical team, we will conduct an in-depth analysis based on your industry needs and provide tailor-made products and solutions. We guarantee to provide you with efficient and accurate services to meet your personalized requirements.

What industries are the products provided by ASLONG suitable for?

ASLONG's products are suitable for multiple industries, including air conditioning and HVAC, construction and waterproofing, automobiles and transportation, home appliances and electronics, industrial equipment and machinery, etc. We provide customized solutions for each industry to meet different needs.

What specific functions can ASLONG's products provide?

Our products cover functions such as insulation, sound insulation, shock absorption, waterproofing and sealing, and are widely used in improving energy efficiency, reducing noise, controlling vibration, protecting equipment, etc., helping customers optimize engineering effects and improve user experience.

Do ASLONG's products meet environmental protection standards?

Yes, all ASLONG products comply with ISO14001 environmental management system certification and global environmental protection standards. We use environmentally friendly materials and are committed to providing sustainable solutions to help customers achieve green development goals.

Does ASLONG provide after-sales service?

Yes, we provide a full range of after-sales services, including technical support, installation guidance, product maintenance and quality tracking, etc., to ensure that each project goes smoothly and continues to perform at its best.

Butyl Rubber Sound Damping Mat

ASLONG Butyl Rubber Sound Damping Mat for sale. Effectively reduces noise and vibrations. High-quality butyl rubber ensures superior performance and durability. Ideal for automotive, industrial, and home applications.

Mass Loaded Vinyl

ASLONG Mass Loaded Vinyl for sale. Reduce noise pollution effectively with our high-quality, mass-loaded vinyl. Ideal for soundproofing walls, floors, and more. Buy now and experience the difference!

Egg Crate Foam

ASLONG Egg Crate Foam for sale. Lightweight, breathable, and comfortable, our egg crate foam provides superior support and pressure relief. Perfect for mattresses, cushions, cars, construction industry, KTV, factories, etc.

NBR Foam

ASLONG NBR Foam: Wholesale NBR foam solutions for diverse applications. High-quality, durable, and competitively priced. Contact us today for bulk orders.

Professional support at any time

If you have any comments or good suggestions, please leave us a message; later our professional staff will contact you as soon as possible.

© 2026 ASLONG All Rights Reserved. Privacy Policy | Terms and Conditions | Sitemap

Whatsapp: +8613242879341

ASLONG Global

ASLONG

Aslong_global