Supply Chain Risks and Sourcing for Car Sound Damping Material

- Supply Chain Risks and Sourcing for Car Sound Damping Material

- Why car sound damping material matters for OEMs and aftermarket installers

- Types of car sound damping material and how they compare

- Primary supply chain risks for car sound damping material

- Raw material and component risk: what to watch for

- Sourcing strategies to reduce disruption for car sound damping material

- Quality assurance, testing and standards important for acoustic performance

- Logistics, packaging and storage considerations

- Regulatory and sustainability factors affecting sourcing

- Cost, weight and performance trade-offs for procurement decisions

- Comparison: sample cost-performance indicators (indicative)

- Supplier qualification checklist for car sound damping material

- How to validate acoustic performance before full production

- ASLONG Car Sound Damping Sheet: product overview and brand advantages

- Procurement checklist tailored for ASLONG Car Sound Damping Sheet

- Actionable steps for purchasing managers and NVH engineers

- FAQ — common questions about car sound damping material and sourcing

- Q: Can damping sheets be replaced by sprays or foams?

- Q: How should damping sheets be stored?

- Q: What documentation should suppliers provide?

- Q: Can Car Sound Damping Sheet be used on EVs?

- Contact and product CTA

- Authoritative references and further reading

- Final procurement checklist (quick reference)

Supply Chain Risks and Sourcing for Car Sound Damping Material

Why car sound damping material matters for OEMs and aftermarket installers

Car sound damping material is a critical component of automotive NVH (noise, vibration, and harshness) strategies. Properly specified damping products improve cabin comfort, reduce road and engine noise, and can increase perceived vehicle quality—important factors for OEMs, conversion shops, and aftermarket retailers. Poorly sourced materials or inconsistent supply can directly affect acoustical performance, warranty claims, and customer satisfaction. This article focuses on practical supply chain risks and sourcing approaches specifically for car sound damping material, with guidance you can apply when evaluating options such as the Car Sound Damping Sheet. To ensure seamless vehicle integration, OEMs must address customization and integration needs for car sound damping sheet OEMs early in the development cycle.

Types of car sound damping material and how they compare

There are several commonly used car sound damping material types. Choosing the right type depends on the noise source, installation area, weight limits, and cost. Below is a concise comparison to help sourcing decisions.

| Material | Typical Use | Effectiveness (Low/Med/High) | Installation Difficulty | Typical Cost (relative) | Durability / Service Life |

|---|---|---|---|---|---|

| Butyl-based Car Sound Damping Sheet (e.g., Car Sound Damping Sheet) | Floor pans, doors, trunks, roof | High (low-frequency vibration damping) | Medium (cut & press on clean metal) | Medium | High (years under normal conditions) |

| Closed-cell foam / EPP / PE foam | Door linings, headliners, trim | Medium (airborne noise reduction) | Easy (adhesive or mechanical fixings) | Low–Medium | Medium |

| Mass-loaded vinyl (MLV) | Bulkhead, firewall, partitions | High (mid–high frequency) | Medium–Hard (heavy, needs adhesives) | High | High |

| Spray-applied damping compounds | Complex shapes, underbody coatings | Low–Medium | Hard (requires equipment) | Low–Medium | Medium |

Primary supply chain risks for car sound damping material

Understanding the primary risks helps procurement teams build resilience. Key risks include: raw-material volatility (butyl rubber, asphalt/bitumen, adhesives, aluminum foil), concentration of suppliers for specialty components, geopolitical or trade restrictions, shipping delays and container shortages, quality variability and counterfeit products, compliance and regulatory risk (REACH, RoHS, flammability standards), and capacity issues during demand surges. Each risk can affect lead time, cost and acoustic performance.

Raw material and component risk: what to watch for

Most automotive damping sheets combine a viscoelastic butyl or bitumen core with an aluminum or polymer facing and a pressure-sensitive adhesive. Price or availability swings in crude oil (affecting bitumen), synthetic rubbers, and aluminum can cause rapid cost rises or lead-time issues. Procurement should track commodity indices and maintain alternative specifications (e.g., butyl blend alternatives or different facing materials) to allow supplier substitution without revalidation.

Sourcing strategies to reduce disruption for car sound damping material

Effective sourcing combines tactical and strategic actions: (1) multi-sourcing: maintain approved primary and secondary suppliers across regions; (2) near-shoring: use geographically closer suppliers for critical volumes to reduce transit risk; (3) safety stock and decoupling inventory: hold buffer inventory for long-lead items; (4) supplier development: co-develop formulations with key suppliers to secure capacity; (5) long-term contracts with price/volume flexibility; (6) qualified substitutes: pre-qualify alternative materials and validate them acoustically; (7) risk-sharing clauses and joint forecasting with suppliers to smooth production planning.

Quality assurance, testing and standards important for acoustic performance

Procurement must demand test data and set clear acceptance criteria. Important tests include peel adhesion (for long-term bonding), dynamic mechanical analysis (DMA) for damping characteristics, temperature cycling and thermal aging, flammability testing (e.g., FMVSS 302 in automotive contexts), and in-situ acoustic tests such as insertion loss or transmission loss measured in standard NVH rigs. Insist on batch traceability, material certificates, and third-party lab reports for critical acoustic metrics.

Logistics, packaging and storage considerations

Sheets and rolls are sensitive to storage temperature and long-term compression. Poor packaging can cause adhesive migration or deformation. Specify packaging that protects edges, prevents moisture ingress, and allows safe stacking. Define acceptable storage temperature ranges and shelf life in contracts. For long lead-time shipments, consider LCL consolidation, negotiated air-freight clauses for critical parts, and Incoterms that clearly allocate risk for transportation delays.

Regulatory and sustainability factors affecting sourcing

Automotive suppliers increasingly must comply with environmental and chemical regulations (REACH, RoHS), end-of-life directives, and supplier sustainability reporting. Materials containing regulated phthalates or heavy metals may be restricted. Request SDS (safety data sheets), SVHC declarations, and environmental compliance certificates. Sustainability requirements may favor recycled facings or bio-based binders; ensure these variants are validated acoustically before approval.

Cost, weight and performance trade-offs for procurement decisions

Sound damping choices are inherently a balance between acoustic performance, weight, cost, and manufacturability. High-performing butyl sheets deliver strong low-frequency damping but add weight; MLV offers excellent airborne sound blocking but is heavy and costly; foams reduce airborne noise with low mass. For mass-sensitive applications (EVs, performance cars) prioritize high loss-per-mass materials. Total cost-of-ownership (material cost + installation time + warranty impact + fuel/efficiency impact from weight) should guide selection, not unit price alone.

Comparison: sample cost-performance indicators (indicative)

Below is a simple indicative comparison to help procurement estimate trade-offs. Numbers are illustrative and should be validated with supplier quotes and laboratory data.

| Material | Typical Cost ($/m2) | Typical Added Weight (kg/m2) | Typical NVH Benefit (relative) |

|---|---|---|---|

| Car Sound Damping Sheet (butyl-based) | 5–12 | 0.6–1.2 | High (vibration & low-frequency) |

| Closed-cell foam | 2–6 | 0.1–0.6 | Medium (airborne) |

| Mass-loaded vinyl | 10–25 | 2.0–4.0 | High (airborne) |

Supplier qualification checklist for car sound damping material

When qualifying suppliers evaluate: manufacturing capacity and redundancy, history of automotive supply (references), in-house QC and testing capabilities, sample testing results (DMA, peel, aging), compliance documentation (SDS, REACH), lead times and logistics partners, packaging quality, warranty and return policies, and the supplier’s approach to continuous improvement and problem response.

How to validate acoustic performance before full production

Pilot runs and acoustic validation are essential. Steps: request engineering samples and perform lab DMA and adhesion tests; install samples on representative vehicle panels and measure insertion loss in an NVH test rig; run environmental aging cycles (heat, humidity, salt spray if relevant) and re-test acoustic performance; and run small vehicle-level pilots to confirm real-world gains. Use standardized test protocols and independent third-party labs when possible.

ASLONG Car Sound Damping Sheet: product overview and brand advantages

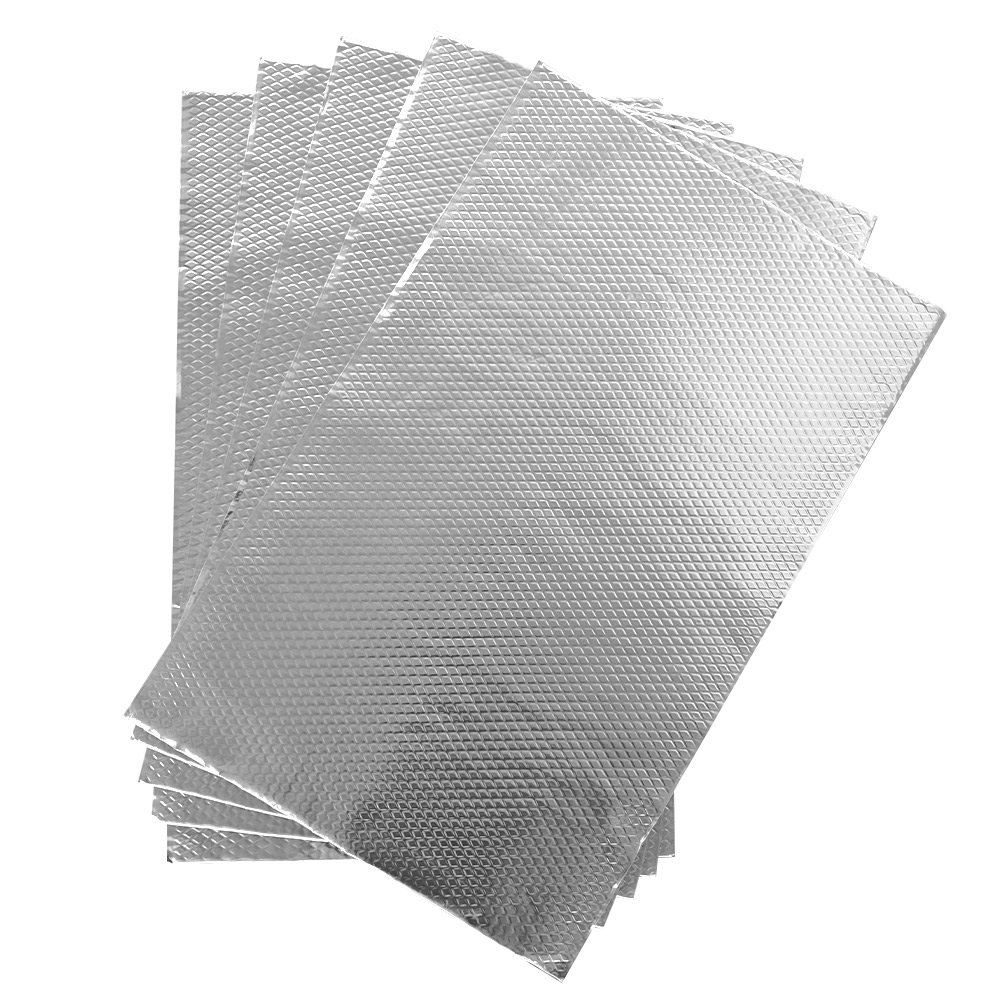

Product: Car Sound Damping Sheet

Product description:

Discover the ASLONG Car Sound Damping Sheet—High Quality sound damping material designed to reduce road noise and vibration. Improve your driving comfort with this easy-to-install, durable car sound damping sheet for superior sound insulation.

ASLONG positions its Car Sound Damping Sheet to meet the needs of OEM retrofit and aftermarket segments by combining reliable butyl-based viscoelastic cores with durable facings and automotive-grade adhesives. Key brand advantages include: consistent batch quality, available test certificates (adhesion, aging, and acoustic insertion loss), flexible MOQ and lead-time options, and responsive technical support to help with installation and NVH tuning. For buyers concerned about supply, ASLONG typically offers multiple roll sizes, reinforced packaging, and contract terms supporting safety stock or scheduled deliveries to stabilize supply.

Procurement checklist tailored for ASLONG Car Sound Damping Sheet

When evaluating ASLONG or similar sheets, confirm: material specification (thickness, mass per area), adhesive tack and heat resistance, certifications (flame, chemical), sample acoustic test results, recommended storage conditions, warranty terms, MOQ, lead time, and whether ASLONG supports custom cuts or pre-formed shapes for assembly line efficiency.

Actionable steps for purchasing managers and NVH engineers

Practical steps: (1) define acoustic targets and allowable weight; (2) request engineering samples and full test data; (3) qualify at least two suppliers and keep validated substitutes; (4) lock critical supplies with flexible long-term agreements; (5) include packaging and shelf-life requirements in contracts; (6) run in-vehicle pilots before volume buys; (7) monitor commodity indicators and supplier capacity monthly.

FAQ — common questions about car sound damping material and sourcing

Q: What is the typical lead time for Car Sound Damping Sheet?

A: Lead times vary by supplier and order size. Standard lead times are 2–6 weeks for stocked items; custom formulations or large volumes may require 8–12 weeks. Negotiate safety-stock or scheduled shipments for critical programs.

Q: Can damping sheets be replaced by sprays or foams?

A: Sprays and foams have valid uses (complex shapes, lightweight airborne control), but they rarely match butyl sheets for low-frequency vibration damping on large metal panels. For floor pans and doors where vibration is primary, Car Sound Damping Sheet remains the preferred choice.

Q: How should damping sheets be stored?

A: Store in a cool, dry place away from direct sunlight, ideally within the supplier-recommended temperature range (often 5–25°C). Avoid heavy stacking that compresses adhesive layers for long periods.

Q: What documentation should suppliers provide?

A: At minimum, provide a technical data sheet (TDS), safety data sheet (SDS), batch traceability, test reports for adhesion and aging, and any regulatory compliance documents (REACH, RoHS). For automotive programs, supply part-specific process instructions and recommended surface prep.

Q: Can Car Sound Damping Sheet be used on EVs?

A: Yes. EVs often require careful NVH tuning because electric drivetrains lack engine masking noise. Use lighter, higher loss-per-mass formulations where weight sensitivity matters, and validate acoustic goals at the vehicle level.

Contact and product CTA

If you want to evaluate samples, request test certificates, or discuss volume pricing and lead times for the Car Sound Damping Sheet, contact our sales team or visit the product page. Our specialists can provide acoustic test data, storage and installation guidance, and tailored supply agreements to reduce your procurement risk. Contact: sales@aslong.example (replace with actual contact) or click to view product and request samples.

Authoritative references and further reading

Below are reputable sources used to inform the guidance in this article. Procurement teams should consult standards and lab data for program-specific validation.

- Noise, vibration, and harshness — Wikipedia: https://en.wikipedia.org/wiki/Noise,_vibration,_and_harshness

- Soundproofing — Wikipedia overview of materials and principles: https://en.wikipedia.org/wiki/Soundproofing

- Environmental Noise — World Health Organization (WHO) fact sheet: https://www.who.int/news-room/fact-sheets/detail/environmental-noise

- Acoustical Society of America — general acoustics resources: https://acousticalsociety.org/

Final procurement checklist (quick reference)

1) Define acoustic and weight targets; 2) Request samples and full test reports; 3) Qualify two or more suppliers; 4) Agree storage, packaging and shelf-life; 5) Run pilot installs and NVH tests; 6) Put flexible long-term agreements in place; 7) Monitor commodity and lead-time indicators monthly.

Wholesale tire noise reduction foam manufacturer and supplier

Tips for buy odorless car sound deadening mat

Design Considerations for Sound Absorbing White Cotton in Projects

How to Choose the egg crate foam for sound deadening manufacturer and supplier ?

FAQs

What industries are the products provided by ASLONG suitable for?

ASLONG's products are suitable for multiple industries, including air conditioning and HVAC, construction and waterproofing, automobiles and transportation, home appliances and electronics, industrial equipment and machinery, etc. We provide customized solutions for each industry to meet different needs.

Does ASLONG provide after-sales service?

Yes, we provide a full range of after-sales services, including technical support, installation guidance, product maintenance and quality tracking, etc., to ensure that each project goes smoothly and continues to perform at its best.

How to customize products that meet the needs of my industry?

You only need to contact our sales or technical team, we will conduct an in-depth analysis based on your industry needs and provide tailor-made products and solutions. We guarantee to provide you with efficient and accurate services to meet your personalized requirements.

What specific functions can ASLONG's products provide?

Our products cover functions such as insulation, sound insulation, shock absorption, waterproofing and sealing, and are widely used in improving energy efficiency, reducing noise, controlling vibration, protecting equipment, etc., helping customers optimize engineering effects and improve user experience.

Do ASLONG's products meet environmental protection standards?

Yes, all ASLONG products comply with ISO14001 environmental management system certification and global environmental protection standards. We use environmentally friendly materials and are committed to providing sustainable solutions to help customers achieve green development goals.

Butyl Rubber Sound Damping Mat

ASLONG Butyl Rubber Sound Damping Mat for sale. Effectively reduces noise and vibrations. High-quality butyl rubber ensures superior performance and durability. Ideal for automotive, industrial, and home applications.

Mass Loaded Vinyl

ASLONG Mass Loaded Vinyl for sale. Reduce noise pollution effectively with our high-quality, mass-loaded vinyl. Ideal for soundproofing walls, floors, and more. Buy now and experience the difference!

Egg Crate Foam

ASLONG Egg Crate Foam for sale. Lightweight, breathable, and comfortable, our egg crate foam provides superior support and pressure relief. Perfect for mattresses, cushions, cars, construction industry, KTV, factories, etc.

NBR Foam

ASLONG NBR Foam: Wholesale NBR foam solutions for diverse applications. High-quality, durable, and competitively priced. Contact us today for bulk orders.

Professional support at any time

If you have any comments or good suggestions, please leave us a message; later our professional staff will contact you as soon as possible.

© 2026 ASLONG All Rights Reserved. Privacy Policy | Terms and Conditions | Sitemap

Whatsapp: +8613242879341

ASLONG Global

ASLONG

Aslong_global