Customization and Integration Needs for Car Sound Damping Sheet OEMs

- Customization and Integration Needs for Car Sound Damping Sheet OEMs

- Why OEMs Should Prioritize Car Sound Damping Material Customization

- Product Overview: Car Sound Damping Sheet

- Key Performance Parameters to Customize in Car Sound Damping Material

- How Keywords Fit Natural OEM Requirements

- Design for Manufacturability: From Prototype to Mass Production

- Integration Example: Door Module Workflow

- NVH Modeling and Test Validation for Car Sound Damping Sheet

- Material Comparisons: Selecting the Right Damping Solution

- Regulatory, Environmental and Safety Requirements

- Quality Control, Testing Protocols, and Supplier KPIs

- Prototyping, Sampling and Co-Development Strategies

- Cost Optimization: Balancing Performance, Weight and Price

- Supply Chain and Logistics Considerations for OEM Integration

- Brand Advantages: Why Choose ASLONG Car Sound Damping Sheet

- Installation Best Practices and Aftermarket Considerations

- Frequently Asked Questions (FAQ)

- Contact Sales / View Product

- Authoritative References

Customization and Integration Needs for Car Sound Damping Sheet OEMs

Why OEMs Should Prioritize Car Sound Damping Material Customization

Automotive original equipment manufacturers (OEMs) face rising expectations for cabin quietness, lightweight construction, and cost efficiency. Choosing the right car sound damping material and tailoring its physical and chemical properties to vehicle architecture is no longer optional — it's central to delivering a competitive driving experience. For manufacturers of the Car Sound Damping Sheet, customization and tight integration with vehicle systems reduce NVH (noise, vibration, and harshness) issues while meeting production and regulatory constraints. After technical integration is planned, decision-makers can justify investments by analyzing total cost of ownership when evaluating car sound damping materials.

Product Overview: Car Sound Damping Sheet

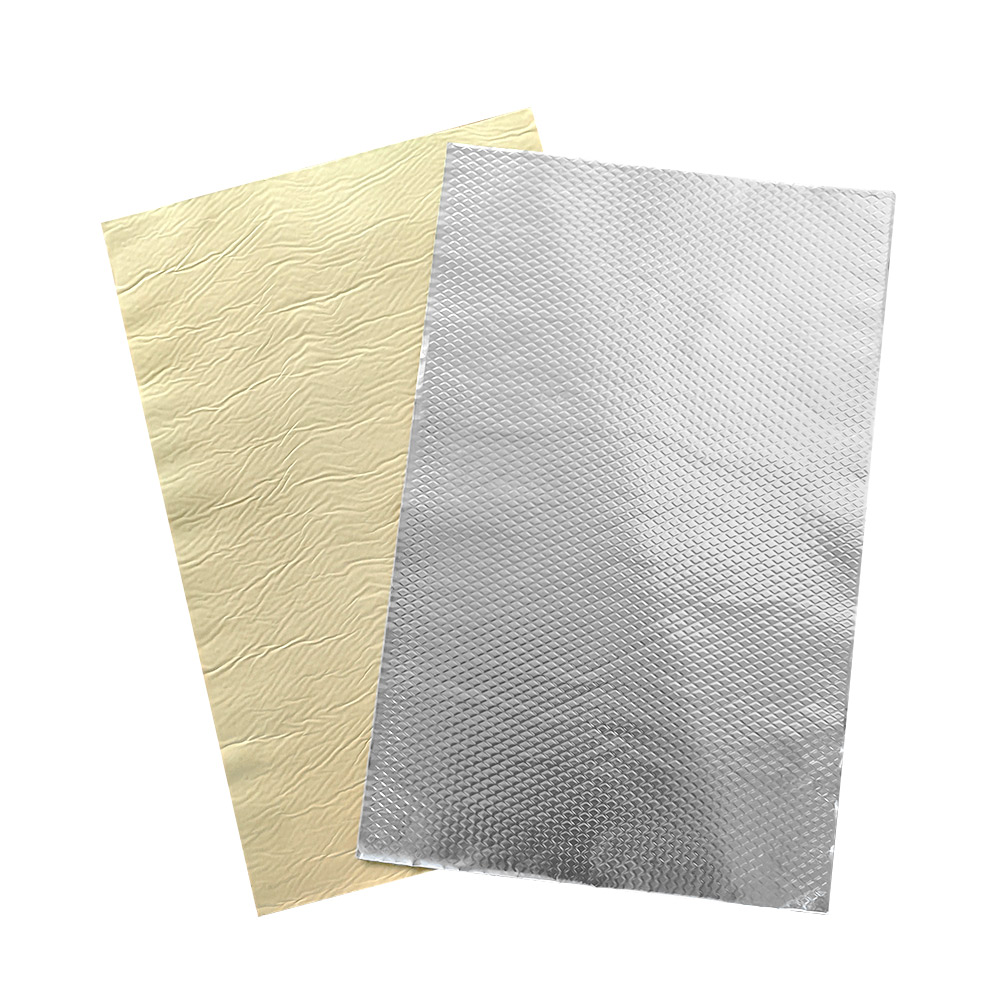

Discover the ASLONG Car Sound Damping Sheet—High Quality sound damping material designed to reduce road noise and vibration. Improve your driving comfort with this easy-to-install, durable car sound damping sheet for superior sound insulation.

Key Performance Parameters to Customize in Car Sound Damping Material

OEMs must specify measurable parameters for any car sound damping material to ensure it meets vehicle targets. Typical properties to define and customize include:

- Damping loss factor and stiffness: Determines how much vibrational energy the sheet dissipates.

- Mass per unit area: Critical tradeoff between acoustic performance and added vehicle weight.

- Thermal operating range: Adhesive and material performance at cold start and under heat soak.

- Adhesive tack and cure behavior: Tack at assembly line temperatures and dwell time to reach final bond strength.

- Thickness and formability: Ability to conform to complex geometries without springback.

- Flammability, smoke, and toxicity: Compliance with FMVSS, UN ECE, or local standards.

- VOC and odor levels: In-cabin air quality concerns during production and lifetime.

How Keywords Fit Natural OEM Requirements

When OEM procurement teams search for car sound damping material suppliers, they often search with transactional intent (e.g., buy car sound damping material or OEM car sound damping sheet supplier). Provide clear spec sheets, sample programs, and customization options to capture this and shorten procurement cycles.

Design for Manufacturability: From Prototype to Mass Production

Integration begins at design. OEMs should work with Car Sound Damping Sheet suppliers to address tooling, die-cutting, and placement methods used on the assembly line. Key integration considerations:

- Die-cut and nest optimization: Minimize waste while ensuring exact registration with stamped panels.

- Robotic placement or manual application: Define adhesive cure windows, vacuum handling needs, and placement tolerances.

- Pre-formed or in-situ forming: Choose pre-molded shapes for complex cavities or flat sheets for floors/doors.

- Packaging and sequencing: Sync packaging orientation with line-side kitting to reduce operator errors.

Integration Example: Door Module Workflow

For door inner panels, a Car Sound Damping Sheet can be customized in both shape and adhesive. A common OEM workflow is:

- 3D scanning of the door inner panel to produce CAD for die tooling.

- Prototype die-cuts delivered for NVH testing.

- Adjustment of adhesive formulation for tack at line temperatures and to allow repositioning for manual assembly.

- Final pre-cut, labeled parts delivered in kitted sequence for JIT line installation.

NVH Modeling and Test Validation for Car Sound Damping Sheet

OEMs should validate damping solutions with both CAE simulation and laboratory testing. A combined approach reduces iterations and time-to-market:

- CAE NVH simulation: Modal analysis and harmonic response help predict where damping will deliver the best return per gram.

- Laboratory testing: Measurements such as Transmission Loss (TL), Sound Reduction Index (SRI), and in-situ modal testing confirm real-world performance.

- Vehicle-level validation: Road-load data and subjective evaluations (comfort scores) ensure the integrated solution meets end-user expectations.

Material Comparisons: Selecting the Right Damping Solution

Below is a concise comparison of common automotive acoustic materials. This helps OEMs choose whether the Car Sound Damping Sheet is the optimal choice for a given application.

| Material | Primary Use | Typical Advantages | Typical Limitations |

|---|---|---|---|

| Car Sound Damping Sheet (butyl/foil, polymer-based) | Panel damping (doors, floor, roof) | High damping per weight, easy to die-cut, strong adhesion | Added mass; needs thermal stability tuning |

| Foam acoustic pads | Absorption in cavities, trims | Lightweight, good mid-frequency absorption, cushioning | Lower structural damping; can outgas if not controlled |

| Mass-loaded vinyl (MLV) | High sound blocking for specific barriers | Excellent barrier properties for low frequencies | Very heavy; limited formability |

| Composite multilayer mats | Combined damping and absorption | Tailored frequency response; reduced total thickness | Higher complexity and cost |

Regulatory, Environmental and Safety Requirements

OEMs must ensure that any Car Sound Damping Sheet complies with market-specific regulations and customer sustainability targets:

- Flammability standards: Meet FMVSS 302 (U.S.), ECE R118, or other local fire safety rules.

- Restricted substances: RoHS, REACH compliance for chemical restrictions in EU markets.

- VOC/odor limits: Ensure low VOC formulations to meet in-cabin air quality specs.

- End-of-life and recyclability: Document material composition and recycling pathways per OEM circularity goals.

Quality Control, Testing Protocols, and Supplier KPIs

Reliable supply is as important as product performance. OEMs should set KPIs and test protocols for Car Sound Damping Sheet suppliers:

- Incoming inspection: Density, thickness, peel strength, and visual checks per lot.

- Process capability (Cp/Cpk): For adhesive coating uniformity and thickness tolerances.

- Environmental aging: Heat-cycling, humidity, and UV exposure tests to ensure long-term stability.

- Traceability: Batch-level records for raw materials and finished parts.

Prototyping, Sampling and Co-Development Strategies

Successful integration often depends on an iterative co-development approach. Recommended steps for OEMs and Car Sound Damping Sheet suppliers:

- Define NVH targets (quantitative and subjective).

- Share CAD and tooling constraints for early feasibility studies.

- Order small-run prototype die-cuts for in-vehicle tests.

- Run a pilot production batch to stress assembly line integration and logistics.

- Lock specs and transition to full production with agreed acceptance criteria.

Cost Optimization: Balancing Performance, Weight and Price

Cost decisions are multi-dimensional. Typical levers include:

- Targeted placement: Apply high-performance Car Sound Damping Sheet only where needed rather than full-coverage.

- Hybrid solutions: Combine thin damping sheets with absorptive foam to reduce total weight.

- Tooling investment: Lifetime cost analysis for die tooling and automation reduces per-unit labor over high volumes.

Supply Chain and Logistics Considerations for OEM Integration

For JIT production, supplier reliability and packaging matter as much as product specs:

- Just-in-time kitting: Ensure correct part orientation, labeling, and quantity per kit.

- Cross-border compliance: Documentation for customs, restricted goods, and safety datasheets.

- Local warehousing for aftermarket: Faster delivery for service centers and retrofit markets.

Brand Advantages: Why Choose ASLONG Car Sound Damping Sheet

When selecting a partner, OEMs should favor suppliers who combine product performance with engineering support:

- Engineering collaboration: ASLONG provides CAD-based die validation, CAE NVH support, and sample prototyping.

- Consistent quality: Tight process control across adhesive coating and die-cutting yields high first-pass assembly success.

- Regulatory readiness: Low-VOC formulations and supply chain transparency simplify certification workstreams.

- Scalability: Flexible manufacturing to support pilot runs and ramp-up to mass production.

Installation Best Practices and Aftermarket Considerations

Proper installation is essential to realize the sheet's designed performance. For OEM and aftermarket installers:

- Surface must be clean, dry and free of oil/adhesive residues.

- Warm the adhesive slightly in cold environments to improve tack.

- Apply firm, uniform pressure after placement to ensure full contact.

- Avoid puncturing the sheet; seal edges near water ingress routes.

Frequently Asked Questions (FAQ)

Q1: What is the main difference between a Car Sound Damping Sheet and acoustic foam?

A: Damping sheets primarily convert vibrational energy into heat (reducing panel resonance), while foam absorbs airborne noise. They are often used together for best results.

Q2: Can the Car Sound Damping Sheet be applied to curved or contoured surfaces?

A: Yes. Suppliers can provide pre-formed shapes or specify thinner, more flexible sheet grades for complex contours. Adhesive and thickness selection are key.

Q3: How do I evaluate a supplier’s claims?

A: Request test reports for TL/SRI, peel strength, thermal cycling, VOC data, and samples for in-vehicle trials. Ask for references from other OEM programs.

Q4: Does adding damping material significantly increase vehicle weight?

A: It can, but strategic placement and lightweight composite constructions minimize mass while delivering targeted NVH gains.

Q5: What certifications should I ask for?

A: Common requests include ISO 9001 (quality management), RoHS/REACH compliance, VOC testing reports, and any market-specific flammability certifications.

Contact Sales / View Product

Ready to integrate a tailored Car Sound Damping Sheet into your vehicle program? Contact our sales and engineering team to request samples, material data sheets, and a co-development plan. View product details at: /product/car-sound-damping-sheet or email sales@example.com to start a project.

Authoritative References

- Soundproofing (overview) — Wikipedia: https://en.wikipedia.org/wiki/Soundproofing

- WHO Environmental Noise Guidelines: https://www.who.int/publications/i/item/9789241508513

- U.S. EPA Noise and Health: https://www.epa.gov/air/noise-health

- Engineering Toolbox — Sound Insulation: https://www.engineeringtoolbox.com/sound-insulation-d_1303.

- CDC NIOSH — Noise and Hearing Loss Prevention: https://www.cdc.gov/niosh/topics/noise/default.

The B2B Buyer’s Guide to Soundproof Cotton Panels

Choosing the Right Sound Deadening Material for Cars 2026

Top 5 car sound deadener Company List and Products Compared

Acoustic Insulation for Floors: Reduce Impact Noise

FAQs

What specific functions can ASLONG's products provide?

Our products cover functions such as insulation, sound insulation, shock absorption, waterproofing and sealing, and are widely used in improving energy efficiency, reducing noise, controlling vibration, protecting equipment, etc., helping customers optimize engineering effects and improve user experience.

How to customize products that meet the needs of my industry?

You only need to contact our sales or technical team, we will conduct an in-depth analysis based on your industry needs and provide tailor-made products and solutions. We guarantee to provide you with efficient and accurate services to meet your personalized requirements.

What industries are the products provided by ASLONG suitable for?

ASLONG's products are suitable for multiple industries, including air conditioning and HVAC, construction and waterproofing, automobiles and transportation, home appliances and electronics, industrial equipment and machinery, etc. We provide customized solutions for each industry to meet different needs.

Does ASLONG provide after-sales service?

Yes, we provide a full range of after-sales services, including technical support, installation guidance, product maintenance and quality tracking, etc., to ensure that each project goes smoothly and continues to perform at its best.

Do ASLONG's products meet environmental protection standards?

Yes, all ASLONG products comply with ISO14001 environmental management system certification and global environmental protection standards. We use environmentally friendly materials and are committed to providing sustainable solutions to help customers achieve green development goals.

Butyl Rubber Sound Damping Mat

ASLONG Butyl Rubber Sound Damping Mat for sale. Effectively reduces noise and vibrations. High-quality butyl rubber ensures superior performance and durability. Ideal for automotive, industrial, and home applications.

Mass Loaded Vinyl

ASLONG Mass Loaded Vinyl for sale. Reduce noise pollution effectively with our high-quality, mass-loaded vinyl. Ideal for soundproofing walls, floors, and more. Buy now and experience the difference!

Egg Crate Foam

ASLONG Egg Crate Foam for sale. Lightweight, breathable, and comfortable, our egg crate foam provides superior support and pressure relief. Perfect for mattresses, cushions, cars, construction industry, KTV, factories, etc.

NBR Foam

ASLONG NBR Foam: Wholesale NBR foam solutions for diverse applications. High-quality, durable, and competitively priced. Contact us today for bulk orders.

Professional support at any time

If you have any comments or good suggestions, please leave us a message; later our professional staff will contact you as soon as possible.

© 2026 ASLONG All Rights Reserved. Privacy Policy | Terms and Conditions | Sitemap

Whatsapp: +8613242879341

ASLONG Global

ASLONG

Aslong_global