Mass Loaded Vinyl and HVAC Noise Mitigation

- Mass Loaded Vinyl and HVAC Noise Mitigation

- What is Mass Loaded Vinyl and why it matters for HVAC noise

- How HVAC noise travels: airborne vs. structure-borne paths

- How Mass Loaded Vinyl works against HVAC noise (science made practical)

- Typical performance: what to expect from Mass Loaded Vinyl

- Where to install Mass Loaded Vinyl for HVAC systems

- Installation best practices to maximize HVAC noise reduction

- Practical case: retrofitting a noisy fan coil room

- Comparing solutions: Mass Loaded Vinyl vs alternatives

- Cost-effectiveness: why choose Mass Loaded Vinyl for HVAC projects

- Fire, code, and indoor air quality considerations

- ASLONG Mass Loaded Vinyl — product introduction

- Why choose ASLONG Mass Loaded Vinyl for HVAC noise mitigation

- Design checklist before specifying Mass Loaded Vinyl

- Maintenance and long-term performance

- FAQs — Mass Loaded Vinyl and HVAC Noise

- Q: Can Mass Loaded Vinyl stop low-frequency HVAC rumble?

- Q: Is MLV suitable for wrapping ductwork?

- Q: How much STC improvement can I expect from adding MLV on a wall?

- Q: Do I need a professional installer?

- Q: How does MLV compare to adding more drywall?

- Contact and next steps — buy Mass Loaded Vinyl or get expert help

- References

Mass Loaded Vinyl and HVAC Noise Mitigation

What is Mass Loaded Vinyl and why it matters for HVAC noise

Mass Loaded Vinyl (MLV) is a dense, flexible barrier specifically manufactured to add mass to walls, ceilings, and floors for sound attenuation. Unlike porous absorbers that target high-frequency reverberation, MLV works by increasing the surface mass and blocking the transmission of airborne sound. For buildings with mechanical systems—fan coils, ductwork, rooftop units, and interior HVAC equipment—controlling airborne noise and vibration paths is crucial. Installing Mass Loaded Vinyl can substantially reduce the perceived noise from HVAC systems without dramatically changing room dimensions or finishes. To expand your options, compare Mass Loaded Vinyl vs Green Glue: soundproofing options, helping you choose the best solution for particular acoustic challenges.

How HVAC noise travels: airborne vs. structure-borne paths

Understanding the main noise transmission paths helps determine where to apply Mass Loaded Vinyl:

- Airborne noise: Sound energy transmitted through the air (e.g., from supply diffusers, return grilles, or open plenums). MLV is effective as a barrier layer on walls, ceilings, and duct surfaces to reduce airborne transmission.

- Structure-borne noise: Vibration transmitted through building structure (e.g., equipment mounted to floors, ductwork conduction). MLV alone is less effective for primary vibration isolation; pairing MLV with resilient mounts, isolation pads, or decoupling methods improves results.

Using Mass Loaded Vinyl as part of an integrated strategy—barriers for airborne noise and isolators for vibration—addresses HVAC noise comprehensively.

How Mass Loaded Vinyl works against HVAC noise (science made practical)

MLV reduces sound transmission by adding surface mass and damping. The added mass lowers the panel’s tendency to vibrate in response to sound pressure; the vinyl's internal damping converts acoustic energy to heat. For HVAC applications, MLV works well when applied behind finishes, inside wall cavities, over existing drywall, or wrapped around ducts to block broadband noise typical of fan and airflow sources.

Typical performance: what to expect from Mass Loaded Vinyl

Performance depends on MLV weight, installation method, and existing construction. Common MLV product weights are 1 lb/ft², 1.5 lb/ft², and 2 lb/ft² (≈4.9, 7.3, 9.8 kg/m²). Typical STC (Sound Transmission Class) improvements when adding a properly installed MLV layer range from 5 to 12 STC points compared to the baseline wall or ceiling—enough to noticeably reduce HVAC hums, fan noise, and airborne duct noise in most retrofit scenarios. For rooms dominated by low-frequency mechanical noise, combining MLV with additional mass or resonant isolation materials yields better results.

Where to install Mass Loaded Vinyl for HVAC systems

Target installations for HVAC noise mitigation include:

- Behind finished drywall on walls adjacent to mechanical rooms or equipment closets.

- On ceilings below mechanical plenum spaces or rooftop unit discharge areas.

- Around ductwork (externally wrapped) to reduce radiated duct-borne noise; use a fire-rated MLV if required by code.

- Inside return and supply plenums (when accessible and compliant with fire/airflow rules).

- On utility chase doors and access panels to seal common leakage paths.

Each location has different code and fire-safety considerations—always verify local building codes and fire ratings when specifying MLV.

Installation best practices to maximize HVAC noise reduction

To get the best performance from Mass Loaded Vinyl:

- Make it continuous: overlap seams and seal with acoustic caulk or specialized seam tape. Even small gaps reduce effectiveness.

- Combine with decoupling where structure-borne transmission exists. Use resilient channels, isolation clips, or vibration pads for equipment mounting.

- Use appropriate fasteners: mechanical fasteners with washers or construction adhesives per manufacturer instructions to avoid compression that reduces damping.

- Respect ventilation and code: do not block required airflow; use fire-rated MLV where necessary.

- Consider composite assemblies: MLV plus additional drywall or a perforated facing can balance aesthetics, fire code, and acoustics.

Practical case: retrofitting a noisy fan coil room

Scenario: Fan coil noise (45–55 dB at adjacent offices) transmitted through a shared wall and return ducting. A cost-effective retrofit often includes:

- Wrap exposed ducts with 1 lb/ft² MLV and seal seams to reduce radiated duct noise.

- Add a 1.5–2.0 lb/ft² MLV layer on the shared wall behind new drywall or over existing drywall, with seams sealed.

- Install resilient hangers for ducts and isolation pads under the fan coil to reduce structure-borne energy.

Outcome: Typical noise reduction of 5–10 dB in the receiving spaces and a perceptible improvement in comfort. Exact results depend on baseline conditions and execution quality.

Comparing solutions: Mass Loaded Vinyl vs alternatives

Below is a comparison of common acoustic strategies for HVAC noise mitigation. Values are typical ranges; specific product datasheets and lab tests should be consulted for design decisions.

| Solution | Typical Mass (kg/m²) | Primary Targets | Typical STC Improvement | Notes |

|---|---|---|---|---|

| Mass Loaded Vinyl (1–2 lb/ft²) | ~4.9–9.8 | Airborne noise, duct radiated noise | 5–12 points | Flexible, thin, easy retrofit; use with isolation for structure-borne noise |

| Additional drywall (1–2 layers) | ~9–18 | Airborne noise | 6–15 points | Effective but increases wall thickness; better with decoupling |

| Resilient channel / isolation clips | Negligible | Structure-borne noise isolation | 4–10 points (combined) | Best when used with mass layers like drywall or MLV |

| Acoustic foam / absorbers | Low | Reverberation and high-frequency noise | Little impact on STC | Useful inside rooms but doesn't block transmission through walls/ceilings |

Sources for ranges: manufacturer technical datasheets and ASTM testing protocols (see references).

Cost-effectiveness: why choose Mass Loaded Vinyl for HVAC projects

MLV often provides a strong cost-to-performance ratio for retrofits where adding full wall thickness or re-routing ductwork is impractical. It is thinner and lighter than adding multiple new gypsum layers and can be applied without major demolition. When budget, schedule, or minimal intrusion are priorities—for example in occupied office spaces, clinics, or hotels—Mass Loaded Vinyl delivers measurable noise reduction quickly.

Fire, code, and indoor air quality considerations

Not all MLV products are equal regarding flame spread and smoke development. For plenum applications or locations with strict fire code requirements, specify a fire-rated MLV and confirm compatibility with HVAC codes. Review manufacturer declarations for VOCs and indoor air quality. ASLONG Mass Loaded Vinyl and other reputable brands provide product datasheets indicating fire ratings and VOC compliance.

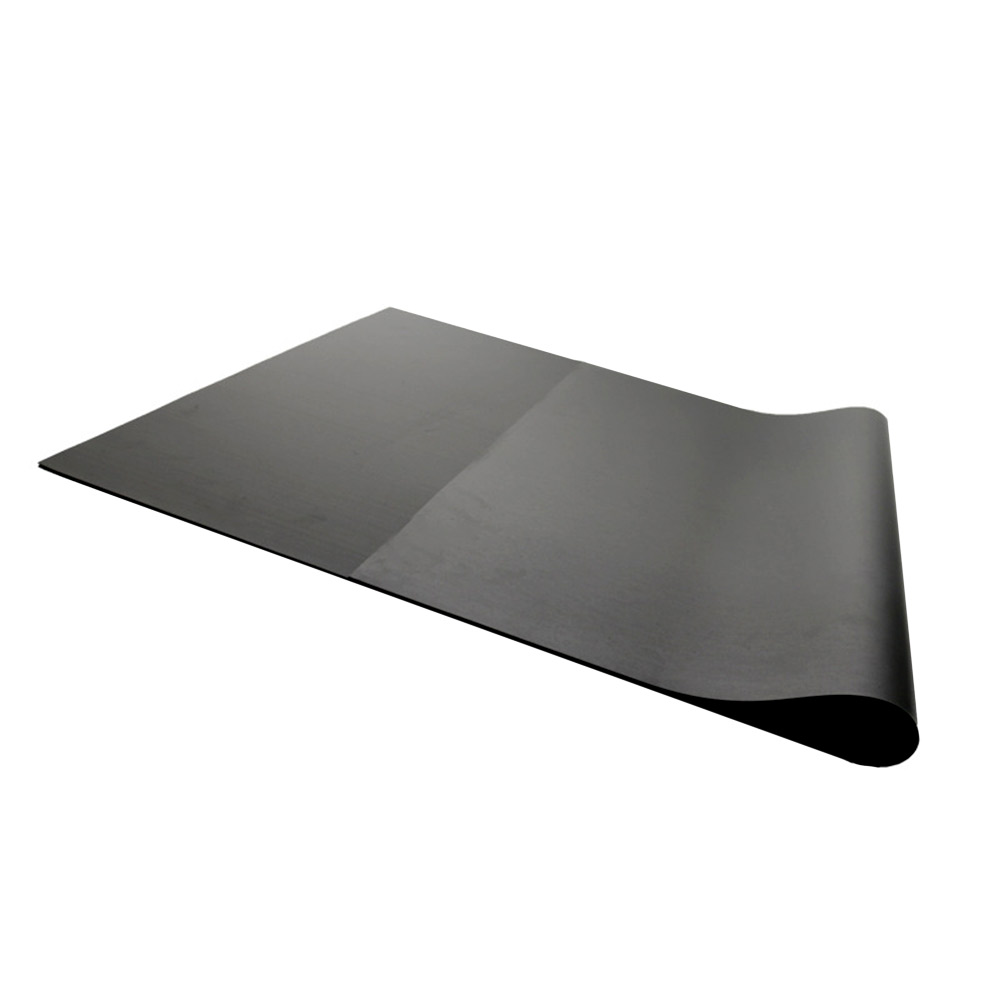

ASLONG Mass Loaded Vinyl — product introduction

ASLONG Mass Loaded Vinyl for sale. Reduce noise pollution effectively with our high-quality, mass-loaded vinyl. Ideal for soundproofing walls, floors, and more. Buy now and experience the difference!

Why choose ASLONG Mass Loaded Vinyl for HVAC noise mitigation

ASLONG offers MLV options tuned for HVAC mitigation challenges: durable flexible rolls, multiple weight options (1.0–2.0 lb/ft²), and installation accessories. Advantages include:

- High mass-to-thickness ratio—effective barrier without consuming significant space.

- Flexible application—wrap ducts, install behind finishes, or line chases.

- Quality control and datasheets—lab-tested STC increments when combined with standard wall/ceiling assemblies.

- Support resources—installation guides and accessory products to ensure proper sealing and fastening.

Design checklist before specifying Mass Loaded Vinyl

Before selecting and installing MLV for HVAC projects, verify:

- Noise source and dominant path (airborne vs. structure-borne).

- Required fire rating and VOC limits for the space.

- Mounting details and whether decoupling/isolation is also needed.

- Accessibility for future HVAC maintenance (don’t obstruct required access panels or dampers).

- Sealing strategy (acoustic caulk, overlap, tape) to avoid flanking paths.

Maintenance and long-term performance

MLV is low maintenance. Keep seams sealed and prevent prolonged UV exposure or chemical contact. For duct wraps, ensure no obstruction to airflow and inspect fasteners annually. When properly installed, MLV maintains performance for many years without significant degradation.

FAQs — Mass Loaded Vinyl and HVAC Noise

Q: Can Mass Loaded Vinyl stop low-frequency HVAC rumble?

A: MLV helps reduce low-frequency airborne components by adding mass, but very low-frequency structural vibration may require isolation mounts, heavier mass layers, or tuned resonant systems. Combine MLV with vibration isolation for best low-frequency control.

Q: Is MLV suitable for wrapping ductwork?

A: Yes—MLV wrapped and sealed around ducts reduces radiated noise and leafing sound. Use a fire-rated product where ducts are within plenums or where code requires. Ensure the wrap does not impede airflow or access for maintenance.

Q: How much STC improvement can I expect from adding MLV on a wall?

A: Typical STC improvement ranges from 5 to 12 points depending on wall construction, MLV weight, and installation quality. For design-level predictions, reference lab test data (ASTM E90) or consult with an acoustical specialist for onsite testing.

Q: Do I need a professional installer?

A: Simple installations (e.g., wrapping accessible ducts or applying MLV over existing drywall) can be DIY for experienced contractors, but complex cases—mechanical rooms, code-sensitive areas, or where isolation is required—benefit from professional acoustical and mechanical coordination.

Q: How does MLV compare to adding more drywall?

A: Additional drywall adds mass and often achieves similar STC gains, but it increases wall thickness, weight, and may require structural reinforcement. MLV provides a thinner, often faster retrofit option with competitive performance, particularly where space is limited.

Contact and next steps — buy Mass Loaded Vinyl or get expert help

Ready to reduce HVAC noise with proven Mass Loaded Vinyl solutions? Contact ASLONG customer service for product details, fire-rating options, and installation guidance. Visit our product page to purchase ASLONG Mass Loaded Vinyl or request a specification sheet and installation quote.

Customer Service: Email: sales@aslong.com | Phone: +1-800-XXX-XXXX

View ASLONG Mass Loaded Vinyl products and buy now

References

- ASTM International — ASTM E90: Standard Test Method for Laboratory Measurement of Airborne Sound Transmission Loss of Building Partitions (https://www.astm.org/Standards/E90.htm)

- ASTM International — ASTM E413: Classification for Rating Sound Insulation (https://www.astm.org/Standards/E413.htm)

- ASHRAE Handbook — HVAC Applications. Guidance on HVAC noise control and acceptable noise criteria (https://www.ashrae.org/technical-resources/ashrae-handbook)

- World Health Organization — Environmental Noise Guidelines for the European Region (2018). Overview of noise impacts on health (https://www.who.int/publications/i/item/9789241550475)

- Acoustical Surfaces — Mass Loaded Vinyl technical information and product datasheets (typical mass and STC guidance) (https://www.acousticalsurfaces.com/mass_loaded_vinyl.htm)

- U.S. Environmental Protection Agency — Noise: a health & environmental resource (https://www.epa.gov/noise)

Top 10 mass loaded vinyl Manufacturers and Supplier Brands

What Is NBR Foam and How Does It Improve Sound Insulation?

Mass Loaded Vinyl for Commercial Spaces: What to Know

What is Acoustic Material

FAQs

What specific functions can ASLONG's products provide?

Our products cover functions such as insulation, sound insulation, shock absorption, waterproofing and sealing, and are widely used in improving energy efficiency, reducing noise, controlling vibration, protecting equipment, etc., helping customers optimize engineering effects and improve user experience.

How to customize products that meet the needs of my industry?

You only need to contact our sales or technical team, we will conduct an in-depth analysis based on your industry needs and provide tailor-made products and solutions. We guarantee to provide you with efficient and accurate services to meet your personalized requirements.

Does ASLONG provide after-sales service?

Yes, we provide a full range of after-sales services, including technical support, installation guidance, product maintenance and quality tracking, etc., to ensure that each project goes smoothly and continues to perform at its best.

What industries are the products provided by ASLONG suitable for?

ASLONG's products are suitable for multiple industries, including air conditioning and HVAC, construction and waterproofing, automobiles and transportation, home appliances and electronics, industrial equipment and machinery, etc. We provide customized solutions for each industry to meet different needs.

Do ASLONG's products meet environmental protection standards?

Yes, all ASLONG products comply with ISO14001 environmental management system certification and global environmental protection standards. We use environmentally friendly materials and are committed to providing sustainable solutions to help customers achieve green development goals.

Butyl Rubber Sound Damping Mat

ASLONG Butyl Rubber Sound Damping Mat for sale. Effectively reduces noise and vibrations. High-quality butyl rubber ensures superior performance and durability. Ideal for automotive, industrial, and home applications.

Mass Loaded Vinyl

ASLONG Mass Loaded Vinyl for sale. Reduce noise pollution effectively with our high-quality, mass-loaded vinyl. Ideal for soundproofing walls, floors, and more. Buy now and experience the difference!

Egg Crate Foam

ASLONG Egg Crate Foam for sale. Lightweight, breathable, and comfortable, our egg crate foam provides superior support and pressure relief. Perfect for mattresses, cushions, cars, construction industry, KTV, factories, etc.

NBR Foam

ASLONG NBR Foam: Wholesale NBR foam solutions for diverse applications. High-quality, durable, and competitively priced. Contact us today for bulk orders.

Professional support at any time

If you have any comments or good suggestions, please leave us a message; later our professional staff will contact you as soon as possible.

© 2026 ASLONG All Rights Reserved. Privacy Policy | Terms and Conditions | Sitemap

Whatsapp: +8613242879341

ASLONG Global

ASLONG

Aslong_global