Mass Loaded Vinyl Acoustic Testing Methods

- Mass Loaded Vinyl Acoustic Testing Methods

- Introduction to mass loaded vinyl and why testing matters

- Key performance metrics for mass loaded vinyl

- Laboratory airborne transmission testing: ASTM E90 / ISO 10140

- Field testing: ASTM E336 / ASTM E413 and measuring insertion loss on-site

- Impact sound and combined systems: ASTM E492 and practical notes

- Measurement equipment, frequency analysis, and data handling

- How to interpret results and set realistic expectations for mass loaded vinyl

- Step-by-step testing checklist when evaluating ASLONG Mass Loaded Vinyl on-site

- Comparison table: common acoustic test standards for MLV

- Common test pitfalls and how to avoid them

- ASLONG Mass Loaded Vinyl: product considerations and brand advantages

- Practical case example: measuring insertion loss on a retrofit partition

- Conclusion and next steps

- FAQ — Mass Loaded Vinyl Acoustic Testing

- Q: What test should I request to verify MLV performance?

- Q: How much dB improvement can I expect from adding MLV?

- Q: Do I need lab testing if I do an in-field insertion loss test?

- Q: Can MLV solve low-frequency noise problems alone?

- Q: What common mistakes reduce MLV effectiveness?

- Contact / View Product

- Sources and references

Mass Loaded Vinyl Acoustic Testing Methods

Introduction to mass loaded vinyl and why testing matters

Mass Loaded Vinyl (MLV) is a high-density, flexible barrier used to reduce airborne sound transmission in walls, floors, ceilings and ducts. Designers, acousticians and building owners rely on test data to understand how a specific MLV product will perform in real installations. Proper acoustic testing verifies claims such as STC or insertion loss, exposes installation weaknesses (flanking paths, leaks), and guides product selection.

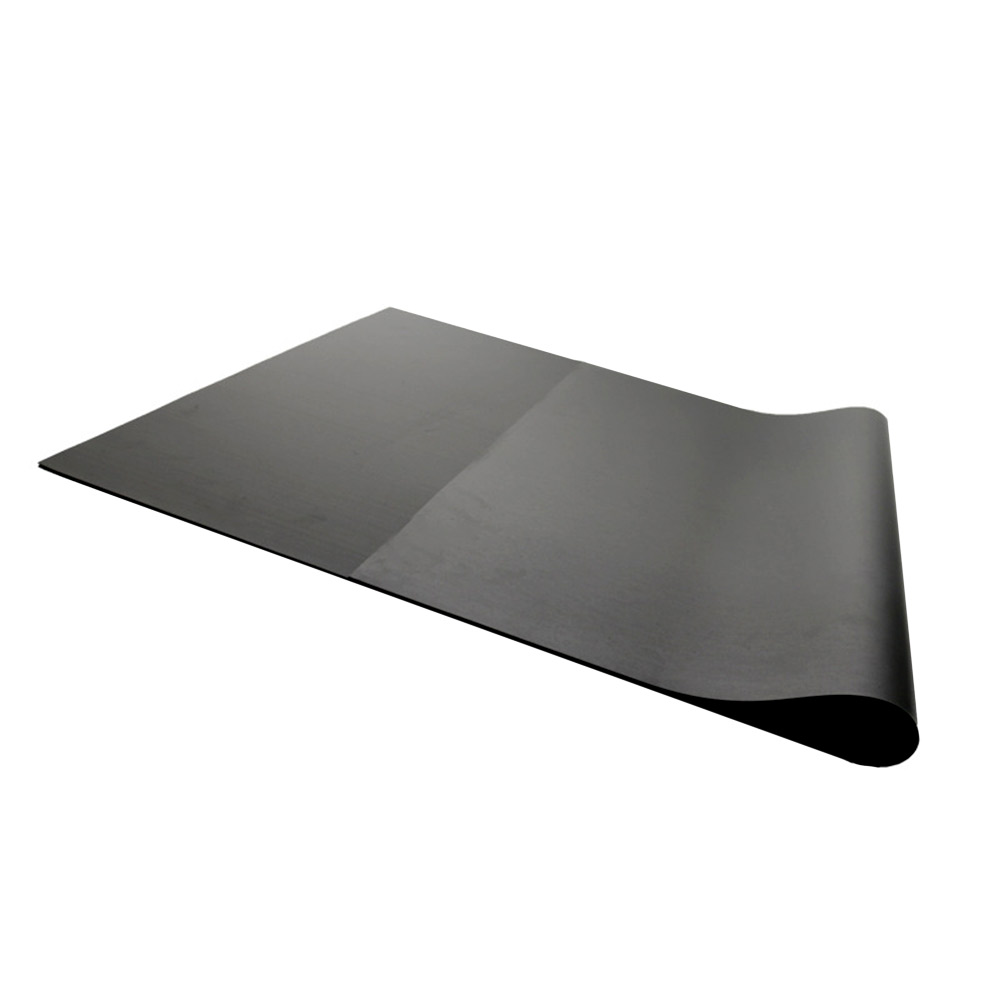

ASLONG Mass Loaded Vinyl for sale. Reduce noise pollution effectively with our high-quality, mass-loaded vinyl. Ideal for soundproofing walls, floors, and more. Buy now and experience the difference!

Key performance metrics for mass loaded vinyl

When testing MLV, the most relevant metrics are:

- Sound Transmission Loss (TL) — the reduction in sound level across a partition in decibels, frequency-dependent.

- Sound Transmission Class (STC) and Rw — single-number ratings derived from laboratory TL curves for common speech frequencies; useful for comparing products.

- Insertion Loss — the dB difference in noise level before and after adding the MLV to an existing assembly in situ (practical measure for retrofits).

- Impact Sound Pressure Level (I/ΔI) — for floors, to measure impact noise; MLV typically affects airborne more than impact noise unless coupled with underlay.

Laboratory airborne transmission testing: ASTM E90 / ISO 10140

ASTM E90 (Standard Test Method for Laboratory Measurement of Airborne Sound Transmission Loss of Building Partitions) and ISO 10140 series are the internationally recognized laboratory methods for measuring TL across a sample partition. In these tests, a test specimen (e.g., a wall assembly with or without MLV) is mounted between two reverberation rooms. A controlled broadband sound is generated on the source side, and sound levels are measured across 1/3-octave bands on the receiving side to compute TL.

Why use lab tests?

- Controlled environment minimizes flanking and room variability.

- Provides frequency-dependent TL curves used to derive STC or Rw.

- Permits repeatable, comparable product claims.

Key laboratory test considerations for MLV:

- Specimen mounting: Whether the MLV is surface-mounted, hung, or sandwiched affects results—tests should match intended installation.

- Sealing of edges and baffling: Lab tests often seal edges to isolate the partition; in-field performance may be lower if edges are not fully sealed.

- Frequency range: Low-frequency performance (below 125 Hz) is crucial for heavy equipment or traffic noise; ensure TL curves include low-frequency data.

Field testing: ASTM E336 / ASTM E413 and measuring insertion loss on-site

Field tests (such as ASTM E336 for airborne sound insulation) measure how a partition performs in its actual building context. Field results account for practical variables like flanking paths, gaps, and construction tolerances. When testing MLV in-situ, practitioners often measure insertion loss—the difference in sound level on the receiving side before and after installing the MLV.

Typical on-site insertion loss procedure:

- Baseline measurement: Measure background noise levels and the transmitted noise spectrum from the source room to the receiver room without MLV installed (use 1/3-octave bands).

- Install MLV per manufacturer recommendations, paying particular attention to edge sealing and overlaps.

- Repeat measurement with the same source levels and microphone positions to compute insertion loss across frequencies.

- Report averaged insertion loss and comment on frequencies where performance is weakest (commonly low frequencies).

Field testing highlights real-world issues like air gaps, HVAC penetrations and flanking through framing—areas where MLV must be combined with other treatments to be fully effective.

Impact sound and combined systems: ASTM E492 and practical notes

ASTM E492 (laboratory measurement of impact sound transmission) and field equivalents measure impact noise (footsteps, dropped objects). Since MLV is primarily a mass barrier, it has limited effect on pure impact noise unless combined with resilient underlayments or floating floor systems. When designing for floors, evaluate both airborne TL improvements and impact sound reduction; test assemblies should reflect the final build-up (e.g., subfloor + resilient layer + MLV + finish).

Measurement equipment, frequency analysis, and data handling

Essential equipment and practices for credible MLV testing:

- Calibrated sound level meters and 1/3-octave analyzers compliant with IEC 61672 or ANSI S1.4.

- Omnidirectional sound sources for lab tests, standard loudspeakers for field tests.

- Microphone arrays or multiple microphone positions to average spatial variability.

- Record and report 1/3-octave band TL or insertion loss values, not just single-number ratings—frequency plots reveal low-frequency weaknesses.

- Document test conditions: room volumes, reverberation times, microphone and source positions, and any sealing or framing details used during the test.

How to interpret results and set realistic expectations for mass loaded vinyl

Interpreting test data requires context. Laboratory STC or Rw ratings give a standardized comparison, but actual field improvement depends on installation quality. Typical patterns to expect:

- MLV increases TL most effectively in mid to high frequencies; low-frequency gains depend on mass and how well the barrier is decoupled from vibrating structures.

- Proper sealing and overlap are crucial—small gaps can dramatically reduce low-frequency performance because sound leaks around the barrier.

- MLV alone rarely solves structure-borne impact noise; pair it with resilient layers or floating floors where impact is a concern.

Step-by-step testing checklist when evaluating ASLONG Mass Loaded Vinyl on-site

Use this practical checklist to validate performance after installing ASLONG MLV:

- Measure baseline ambient and transmitted noise levels (1/3-octave bands) with the room in normal operational state.

- Inspect installation: ensure continuous overlaps, sealed seams with acoustic sealant, and no gaps at penetrations or perimeters.

- Re-measure transmitted noise with the same test signal and microphone locations.

- Calculate insertion loss across frequencies and report both the 1/3-octave plot and a summarized STC estimate if needed.

- If results are below expectations, check for flanking paths, HVAC, windows, doors, and slab or framing resonances that require additional treatment.

Comparison table: common acoustic test standards for MLV

| Test / Standard | Primary Purpose | Typical Output | When to Use |

|---|---|---|---|

| ASTM E90 | Laboratory airborne sound transmission loss | TL vs frequency; used to derive STC | Product development and lab verification of MLV assemblies |

| ISO 10140 | Laboratory measurement of sound insulation (airborne and impact) | Frequency TL, impact results; used for Rw | International lab comparisons |

| ASTM E336 / E413 | Field airborne sound insulation; classification (E413) | Field transmission loss; field STC (if calculated) | On-site verification of installed MLV |

| ASTM E492 | Laboratory impact sound transmission | Impact Sound Pressure Level (ISPL) | Floor systems testing when MLV used with floor assemblies |

Sources: ASTM International and ISO standards (listed below).

Common test pitfalls and how to avoid them

To ensure test results represent real-world performance:

- Avoid testing with unsealed seams—seal all overlaps and perimeter joints as you would in final construction.

- Document and control source levels and microphone positions; inconsistent geometry invalidates pre/post comparisons.

- Account for flanking paths—door frames, windows, HVAC, and structure-borne coupling can dominate the measured transfer.

- When using single-number ratings (STC, Rw), still inspect frequency-specific TL to identify low-frequency problems.

ASLONG Mass Loaded Vinyl: product considerations and brand advantages

When selecting an MLV product, factors beyond lab numbers matter: product density, flexibility for tight details, fire/smoke ratings, ease of installation, and post-sale technical support. ASLONG Mass Loaded Vinyl offers:

- Consistent manufacturing density and thickness options to match design targets.

- Pre-cut widths and custom lengths to reduce on-site seams and save labor.

- Technical documentation and recommended installation details that help you reproduce lab-level performance in the field.

- Quality control and stock availability for fast shipments to job sites.

These advantages reduce the gap between laboratory-tested performance and real-world results by emphasizing proper installation, which is as important as the product itself.

Practical case example: measuring insertion loss on a retrofit partition

Scenario: An office with a shared wall experiences speech noise from the neighboring room. Baseline field measurements (A-weighted 1/3-octave spectra) are taken at the receiver position. ASLONG MLV is applied as a surface-layer on the partition with sealed overlaps.

Procedure:

- Baseline: Measure transmitted noise with a steady broadband source in source room; record 1/3-octave bands 100–5000 Hz.

- Install ASLONG MLV per instructions, seal perimeters with acoustic sealant.

- Re-measure. Compute insertion loss per 1/3-octave band and summarize typical dB improvement across mid-high frequencies. If needed, add a second layer or decoupling channel for improved low-frequency results.

Note: Results will vary by site; the measurement process confirms actual in-room benefit and identifies remaining leakage paths for targeted follow-up.

Conclusion and next steps

Understanding testing is incomplete without knowing Mass Loaded Vinyl maintenance and longevity, ensuring your investment continues to perform over time.Valid acoustic testing—both laboratory and field—is essential to understand how Mass Loaded Vinyl will perform in your project. Use ASTM and ISO methods for standardized comparisons, and always perform in-situ insertion loss tests to validate installed performance. Pay close attention to installation details (seams, perimeters, penetrations) because these determine whether lab-rated performance translates to real noise reduction. For reliable MLV supply and installation guidance, ASLONG provides product consistency, technical documentation, and customer support to help you achieve test-proven outcomes.

FAQ — Mass Loaded Vinyl Acoustic Testing

Q: What test should I request to verify MLV performance?

A: For product comparison, request laboratory TL data (ASTM E90 or ISO 10140) and the derived STC or Rw. For on-site verification, request insertion loss measurements using field methods (ASTM E336) or a documented before/after 1/3-octave test.

Q: How much dB improvement can I expect from adding MLV?

A: Improvements depend on the existing assembly and installation quality. MLV typically provides the most improvement at mid-high frequencies. Exact dB gains vary; the only reliable way to know is to measure baseline and post-installation using the procedures described above.

Q: Do I need lab testing if I do an in-field insertion loss test?

A: Lab testing gives standardized comparison data; field insertion loss measures real-world benefit. Both are valuable: lab for product selection and design, field for verification after installation.

Q: Can MLV solve low-frequency noise problems alone?

A: Low-frequency noise is challenging. Higher-mass MLV layers and decoupling help, but often you must combine MLV with resilient mounts, additional mass layers, or tuned absorbers. Low-frequency results should be validated with 1/3-octave measurements.

Q: What common mistakes reduce MLV effectiveness?

A: Gaps at seams and perimeters, unsecured overlaps, unsealed penetrations for outlets or pipes, and ignoring flanking paths are the most common mistakes. Follow the manufacturer’s installation guide and verify with field testing.

Contact / View Product

To order samples, request technical data, or schedule an on-site performance consultation, contact ASLONG customer service or visit our product page to Buy ASLONG Mass Loaded Vinyl and get installation guidance tailored to your project.

Sources and references

The standards and organizations referenced in this article are authoritative references for acoustic testing and product assessment:

- ASTM E90 — Standard Test Method for Laboratory Measurement of Airborne Sound Transmission Loss of Building Partitions. ASTM International.

- ASTM E336 — Standard Test Method for Measurement of Airborne Sound Transmission Loss of Building Partitions and Elements. ASTM International.

- ASTM E492 — Standard Test Method for Laboratory Measurement of Impact Sound Transmission Through Floor-Ceiling Assemblies. ASTM International.

- ASTM E413 — Classification for Rating Sound Insulation. ASTM International.

- ISO 10140 series — Acoustics — Laboratory measurement of sound insulation of building elements. International Organization for Standardization (ISO).

- ISO 717-1 — Acoustics — Rating of sound insulation in buildings and of building elements — Part 1: Airborne sound insulation. ISO.

- IEC 61672 / ANSI S1.4 — Standards for sound level meters and measurement equipment calibration.

What is sound insulation materials

Tips for buy car sound deadening mat

Top 10 sound deadening insulation for cars Manufacturers and Supplier Brands

Environmental Impact and Recycling of NBR Foam Materials

FAQs

Does ASLONG provide after-sales service?

Yes, we provide a full range of after-sales services, including technical support, installation guidance, product maintenance and quality tracking, etc., to ensure that each project goes smoothly and continues to perform at its best.

What industries are the products provided by ASLONG suitable for?

ASLONG's products are suitable for multiple industries, including air conditioning and HVAC, construction and waterproofing, automobiles and transportation, home appliances and electronics, industrial equipment and machinery, etc. We provide customized solutions for each industry to meet different needs.

Do ASLONG's products meet environmental protection standards?

Yes, all ASLONG products comply with ISO14001 environmental management system certification and global environmental protection standards. We use environmentally friendly materials and are committed to providing sustainable solutions to help customers achieve green development goals.

What specific functions can ASLONG's products provide?

Our products cover functions such as insulation, sound insulation, shock absorption, waterproofing and sealing, and are widely used in improving energy efficiency, reducing noise, controlling vibration, protecting equipment, etc., helping customers optimize engineering effects and improve user experience.

How to customize products that meet the needs of my industry?

You only need to contact our sales or technical team, we will conduct an in-depth analysis based on your industry needs and provide tailor-made products and solutions. We guarantee to provide you with efficient and accurate services to meet your personalized requirements.

Butyl Rubber Sound Damping Mat

ASLONG Butyl Rubber Sound Damping Mat for sale. Effectively reduces noise and vibrations. High-quality butyl rubber ensures superior performance and durability. Ideal for automotive, industrial, and home applications.

Mass Loaded Vinyl

ASLONG Mass Loaded Vinyl for sale. Reduce noise pollution effectively with our high-quality, mass-loaded vinyl. Ideal for soundproofing walls, floors, and more. Buy now and experience the difference!

Egg Crate Foam

ASLONG Egg Crate Foam for sale. Lightweight, breathable, and comfortable, our egg crate foam provides superior support and pressure relief. Perfect for mattresses, cushions, cars, construction industry, KTV, factories, etc.

NBR Foam

ASLONG NBR Foam: Wholesale NBR foam solutions for diverse applications. High-quality, durable, and competitively priced. Contact us today for bulk orders.

Professional support at any time

If you have any comments or good suggestions, please leave us a message; later our professional staff will contact you as soon as possible.

© 2026 ASLONG All Rights Reserved. Privacy Policy | Terms and Conditions | Sitemap

Whatsapp: +8613242879341

ASLONG Global

ASLONG

Aslong_global