Choosing the Right Mass Loaded Vinyl for Walls

- Choosing the Right Mass Loaded Vinyl for Walls

- How Mass Loaded Vinyl (MLV) Works and Why It Matters

- ASLONG Mass Loaded Vinyl Product Overview

- Key Specifications to Evaluate When Choosing MLV

- Typical Performance Expectations (What Does MLV Achieve?)

- Comparing Common MLV Options — Table of Typical Properties

- How to Choose the Right Weight and Thickness for Walls

- Installation Methods That Maximize MLV Effectiveness

- Common Mistakes That Reduce MLV Performance

- MLV vs. Other Soundproofing Options

- Cost Considerations and ROI

- Selecting MLV for Specific Use Cases

- Environmental, Safety and Regulatory Notes

- Why Choose ASLONG Mass Loaded Vinyl — Brand Advantages

- Practical Checklist Before Buying MLV

- Installation Example: Step-by-step for Retrofitting a Shared Wall

- Realistic Testing and Verification

- Frequently Asked Questions (FAQ)

- Q: Will Mass Loaded Vinyl stop low-frequency bass?

- Q: How thick should MLV be for a bedroom wall?

- Q: Can I install MLV myself?

- Q: Is MLV safe and environmentally friendly?

- Q: How much space does MLV add to a wall?

- Contact to Buy or Learn More

- References and Sources

Choosing the Right Mass Loaded Vinyl for Walls

How Mass Loaded Vinyl (MLV) Works and Why It Matters

Mass Loaded Vinyl (MLV) is a high-mass, flexible barrier material designed to reduce airborne sound transmission through walls, ceilings and floors. Unlike absorptive materials that trap sound energy, MLV increases the surface mass and blocks transmission — the core principle behind soundproofing: more mass equals less transmitted sound at mid and high frequencies. For practical wall applications, MLV is typically applied directly to studs, existing drywall, or as part of a decoupled wall assembly.

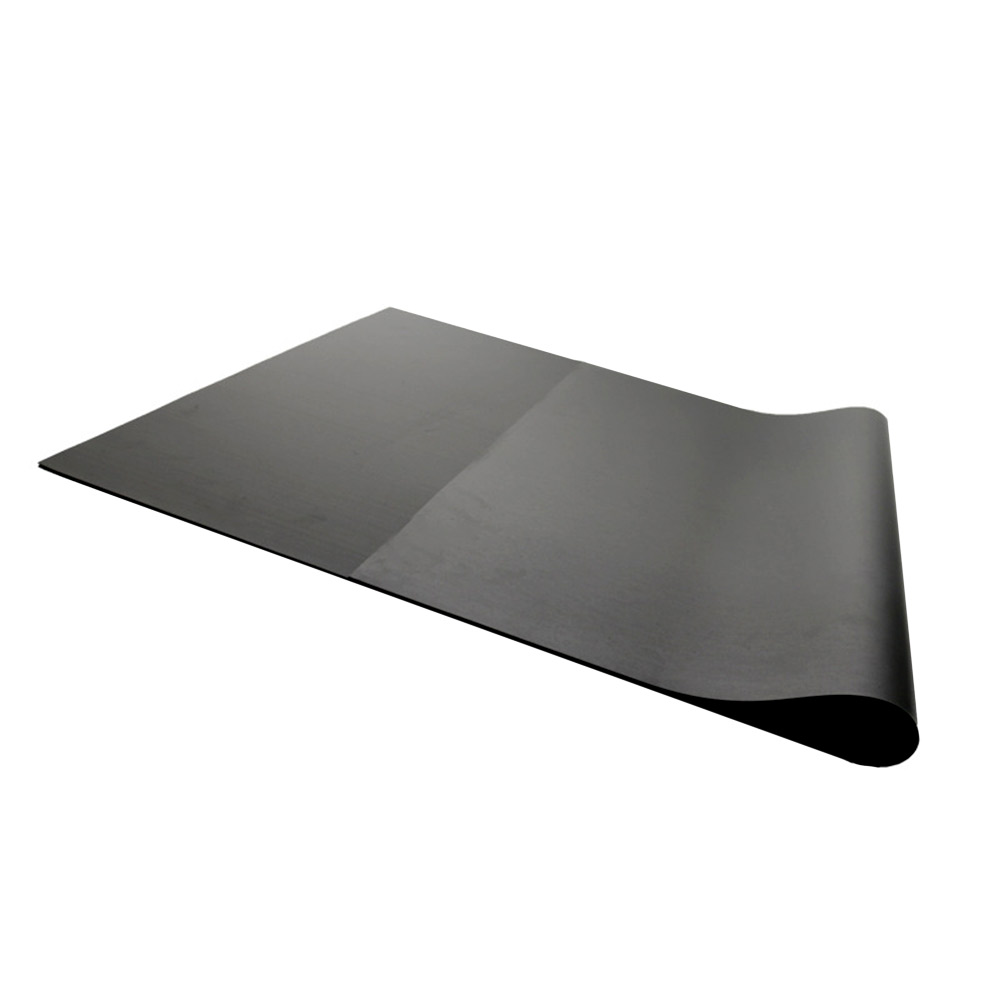

ASLONG Mass Loaded Vinyl Product Overview

ASLONG Mass Loaded Vinyl for sale. Reduce noise pollution effectively with our high-quality, mass-loaded vinyl. Ideal for soundproofing walls, floors, and more. Buy now and experience the difference!

Key Specifications to Evaluate When Choosing MLV

Choosing the right MLV starts with understanding three core specifications: mass per unit area (commonly lb/ft² or kg/m²), thickness, and composition (lead-based historically vs. modern lead-free blends). These determine the product's ability to block sound, its flexibility for installation, and its suitability for different wall builds.

- Mass per area: The single most important metric. Typical MLV options are 0.5–2.0 lb/ft² (≈2.4–9.8 kg/m²). Higher mass generally increases sound-blocking effectiveness, especially at low-mid frequencies.

- Thickness: Thicker MLV can be stiffer; common thickness ranges from 1.5 mm to 4 mm. Thickness affects handling and how the product integrates with framing and trim.

- Composition & durability: Modern MLV uses heavy polymers and mineral loads (lead-free) for regulatory and environmental reasons. Check tear strength, temperature tolerance, and compatibility with adhesives or fasteners.

Typical Performance Expectations (What Does MLV Achieve?)

Expect MLV to provide noticeable reduction in airborne noise — voices, music, and television — when installed correctly. Realistic improvements in Sound Transmission Class (STC) depend on the overall wall assembly. MLV alone does not magically produce high STC ratings; it's most effective when used with other measures: adding mass (MLV), decoupling (resilient channels or double-stud walls), and absorption (insulation in cavities).

Comparing Common MLV Options — Table of Typical Properties

The table below summarizes typical MLV variants and expected relative performance. Values are typical ranges and should be confirmed by manufacturer technical data sheets and lab test reports.

| MLV Type | Mass (lb/ft²) | Thickness (mm) | Typical STC Improvement* | Best Use |

|---|---|---|---|---|

| Lightweight MLV | 0.5–0.75 | 1.2–2.0 | 3–6 points | Temporary barriers, light renovations |

| Standard MLV | 1.0–1.5 | 2.0–3.0 | 5–9 points | Residential walls, home studios |

| Heavy MLV | 1.5–2.0+ | 3.0–4.5 | 7–12 points | Commercial partitions, high-noise requirements |

*STC improvement is approximate and depends on the original wall assembly, installation quality, and frequency content of the noise. Source data summarized from industry technical guidance and manufacturer test reports (see references).

How to Choose the Right Weight and Thickness for Walls

Select MLV weight by balancing performance needs, budget, and installation practicality:

- If you need small-to-moderate reduction (e.g., reduce TV volume between rooms), standard 1 lb/ft² MLV often works well.

- For more demanding situations (busy streets, shared walls with heavy low-frequency noise), pick 1.5–2.0 lb/ft² if your framing and finish work can support it.

- If you’re retrofitting without removing drywall, use thinner/flexible options that can be applied over studs or under new drywall layers.

Installation Methods That Maximize MLV Effectiveness

Correct installation is as important as product selection. Common methods:

- Direct mount under new drywall: Fasten MLV to studs, then apply a new layer of drywall. Seal all seams with acoustical caulk.

- Overlay on existing drywall: Apply MLV directly over the existing surface and add a new layer of drywall for a quicker retrofit.

- Decoupled assemblies: Combine MLV with resilient channels or a staggered/double-stud wall for strong low-frequency performance.

Key installation tips: overlap seams by manufacturer recommendations, use acoustic sealant at perimeters, avoid compressing MLV into cavities (it should be continuous as a barrier), and fasten with proper washers or screws to prevent tear-out.

Common Mistakes That Reduce MLV Performance

Many projects underperform because of these avoidable errors:

- Not sealing seams and perimeters — even small gaps let a lot of sound through.

- Relying on MLV alone without addressing flanking paths (e.g., outlets, gaps around doors, ventilation ducts).

- Compressing or puncturing MLV during installation — maintain continuity and avoid unnecessary fasteners.

- Using MLV of insufficient mass for the target noise problem (especially low-frequency noise).

MLV vs. Other Soundproofing Options

MLV is a mass-based barrier and works best when combined with absorptive and decoupling strategies. Here's a brief comparison:

- Compared to acoustic foam: Foam absorbs interior reflections but does not block sound transmission through walls—MLV is required for blocking.

- Compared to extra drywall: Adding mass by another drywall layer helps; combining drywall + MLV is more effective per inch than drywall alone.

- Compared to resilient channels: Channels decouple drywall from studs to reduce vibration transfer. Using channels + MLV gives both isolation and added mass.

Cost Considerations and ROI

MLV cost is usually quoted per square foot. Higher mass products cost more but may save labor because you need fewer additional modifications. Consider long-term returns: better sleep, higher residential comfort, increased property value and fewer complaints in multi-family or commercial settings. For many buyers, a properly selected MLV delivers high value because it targets a core physical mechanism—blocking sound by mass.

Selecting MLV for Specific Use Cases

Practical recommendations by use-case:

- Home theater: Use standard-to-heavy MLV (1.0–1.5+ lb/ft²) combined with insulation and decoupling for low-frequency control.

- Shared apartment wall: 1.0–1.5 lb/ft² MLV applied with acoustic sealant and a new drywall layer often gives substantial improvement.

- Commercial offices: Heavy MLV in partitions plus resilient channels and acoustic sealants achieves compliance with speech privacy goals.

Environmental, Safety and Regulatory Notes

Historically, some MLV used lead to achieve mass. Modern, responsible manufacturers (including ASLONG) use lead-free formulations for environmental, health and regulatory compliance. When selecting MLV, request product safety data sheets (SDS) and evidence of lead-free composition if that matters for building codes or client preference.

Why Choose ASLONG Mass Loaded Vinyl — Brand Advantages

ASLONG Mass Loaded Vinyl combines industry-grade acoustic performance with practical installation features and environmental responsibility:

- Proven acoustic performance: Engineered formulations for consistent mass-per-area metrics that deliver predictable sound-blocking gains.

- Lead-free and compliant: Modern, safe materials and published SDS documentation.

- Easy installation: Flexible sheets that conform to studs and irregular surfaces, with edges designed for effective seam sealing.

- Commercial support: Technical guidance for installers and specifiers to optimize assemblies and ensure real-world performance.

Practical Checklist Before Buying MLV

Use this buying checklist to make sure you select the right product and get the results you expect:

- Identify target noise type (voices, traffic, low-frequency bass).

- Measure wall area and check existing wall construction (single stud, double stud, insulated cavity?).

- Decide if retrofit or full rebuild—this affects choice of weight/thickness.

- Request manufacturer STC/Evaluator data for the MLV product in assemblies similar to yours.

- Plan for sealing, doors, electrical outlets and HVAC flanking paths.

Installation Example: Step-by-step for Retrofitting a Shared Wall

Typical retrofit steps for a shared apartment wall:

- Remove baseboards and outlet covers. Identify studs and clear work area.

- Apply acoustic sealant to perimeter edges where MLV will meet floor and ceiling.

- Hang MLV horizontally or vertically per manufacturer, overlapping seams by the recommended amount and sealing overlaps.

- Fasten with appropriate screws and large-diameter washers to reduce pull-through risk.

- Install a new layer of 5/8 (or specified) drywall over the MLV, sealing edges and finishing as required.

- Reinstall trim and test performance (use simple A/B listening, phone decibel app or hire acoustic testing if required).

Realistic Testing and Verification

If project stakes are high (commercial or multi-family compliance), consider lab or field testing (ASTM E90 for airborne transmission or field test ASTM E336/ISO 140-4). For most residential projects, pre- and post-installation measurements with a sound-level meter and consistent source (e.g., recorded test tones or music) will give a practical view of improvement.

Frequently Asked Questions (FAQ)

Q: Will Mass Loaded Vinyl stop low-frequency bass?

A: MLV helps reduce low-mid frequencies but is less effective by itself at very low bass (sub-bass). Combine MLV with decoupling (resilient channels, double studs) and sufficient wall mass for stronger low-frequency performance.

Q: How thick should MLV be for a bedroom wall?

A: For typical bedroom noise (conversations, TV), 1.0–1.5 lb/ft² MLV is a good balance of performance and convenience. Pair with acoustic sealant and a new drywall layer for best results.

Q: Can I install MLV myself?

A: Competent DIYers can install MLV following manufacturer instructions. Key skills: measuring/cutting, sealing seams, correct fastening and finishing drywall. For complex or high-stakes projects, professional installers are recommended.

Q: Is MLV safe and environmentally friendly?

A: Modern MLV products from reputable brands (like ASLONG) are lead-free and come with SDS documentation. Verify with the supplier if environmental or regulatory compliance is important for your project.

Q: How much space does MLV add to a wall?

A: MLV is relatively thin (typically 1.5–4.5 mm) but when combined with additional drywall it will increase wall thickness by the assembly layers. Plan trim and electrical box extensions accordingly.

Contact to Buy or Learn More

If you’re ready to buy or need help choosing the right Mass Loaded Vinyl for walls, contact ASLONG today or view product specifications and pricing on our product page. Our technical team can recommend the correct weight and installation approach for your project to ensure you get the performance you need.After selecting the best material for wall soundproofing, you may also want to improve noise control from above. To explore ceiling solutions, continue with Mass Loaded Vinyl for Ceiling Noise Reduction.

References and Sources

- Acoustical Surfaces — Mass Loaded Vinyl Overview and Technical Guide: https://www.acousticalsurfaces.com

- Soundproofing Company — Mass Loaded Vinyl Product Data and Installation Tips: https://www.soundproofingcompany.com

- ASTM Standards — E90 (Laboratory Measurement of Airborne Sound Transmission loss): https://www.astm.org (standard reference)

- Acoustical Society of America — Principles of Sound Transmission and Control: https://acousticalsociety.org

Comparing Foam vs. Rubber Sound Insulation 2026

The B2B Buyer’s Guide to Automotive Soundproofing Material

Mass Loaded Vinyl for Industrial Noise Control

NBR Foam for HVAC Noise Control: Applications and Tips

FAQs

How to customize products that meet the needs of my industry?

You only need to contact our sales or technical team, we will conduct an in-depth analysis based on your industry needs and provide tailor-made products and solutions. We guarantee to provide you with efficient and accurate services to meet your personalized requirements.

What industries are the products provided by ASLONG suitable for?

ASLONG's products are suitable for multiple industries, including air conditioning and HVAC, construction and waterproofing, automobiles and transportation, home appliances and electronics, industrial equipment and machinery, etc. We provide customized solutions for each industry to meet different needs.

Does ASLONG provide after-sales service?

Yes, we provide a full range of after-sales services, including technical support, installation guidance, product maintenance and quality tracking, etc., to ensure that each project goes smoothly and continues to perform at its best.

What specific functions can ASLONG's products provide?

Our products cover functions such as insulation, sound insulation, shock absorption, waterproofing and sealing, and are widely used in improving energy efficiency, reducing noise, controlling vibration, protecting equipment, etc., helping customers optimize engineering effects and improve user experience.

Do ASLONG's products meet environmental protection standards?

Yes, all ASLONG products comply with ISO14001 environmental management system certification and global environmental protection standards. We use environmentally friendly materials and are committed to providing sustainable solutions to help customers achieve green development goals.

Butyl Rubber Sound Damping Mat

ASLONG Butyl Rubber Sound Damping Mat for sale. Effectively reduces noise and vibrations. High-quality butyl rubber ensures superior performance and durability. Ideal for automotive, industrial, and home applications.

Mass Loaded Vinyl

ASLONG Mass Loaded Vinyl for sale. Reduce noise pollution effectively with our high-quality, mass-loaded vinyl. Ideal for soundproofing walls, floors, and more. Buy now and experience the difference!

Egg Crate Foam

ASLONG Egg Crate Foam for sale. Lightweight, breathable, and comfortable, our egg crate foam provides superior support and pressure relief. Perfect for mattresses, cushions, cars, construction industry, KTV, factories, etc.

NBR Foam

ASLONG NBR Foam: Wholesale NBR foam solutions for diverse applications. High-quality, durable, and competitively priced. Contact us today for bulk orders.

Professional support at any time

If you have any comments or good suggestions, please leave us a message; later our professional staff will contact you as soon as possible.

© 2026 ASLONG All Rights Reserved. Privacy Policy | Terms and Conditions | Sitemap

Whatsapp: +8613242879341

ASLONG Global

ASLONG

Aslong_global