Butyl Rubber Sound Damping Mat vs other soundproofing materials

- Butyl Rubber Sound Damping Mat vs other soundproofing materials

- What is the Butyl Rubber Sound Damping Mat and product snapshot

- How a butyl rubber sheet works: principles and benefits

- Common soundproofing materials: quick overview

- Performance comparison table: butyl rubber mat vs other materials

- When to choose butyl rubber sheet over other options

- Installation guidance and best practices for optimal results

- Durability, maintenance and environmental considerations

- Cost and lifecycle: is butyl a cost-effective choice?

- How to choose the right damping product: decision checklist

- Why choose ASLONG Butyl Rubber Sound Damping Mat

- Practical examples and common applications

- FAQ

- Q: Can I use a butyl rubber mat alone to soundproof a room?

- Q: Is butyl rubber safe for use in vehicles?

- Q: How thick should the butyl sheet be for best results?

- Q: Do butyl mats smell or emit VOCs?

- Q: How do I maintain installed butyl damping mats?

- Contact and product access

- Authoritative references and further reading

Butyl Rubber Sound Damping Mat vs other soundproofing materials

What is the Butyl Rubber Sound Damping Mat and product snapshot

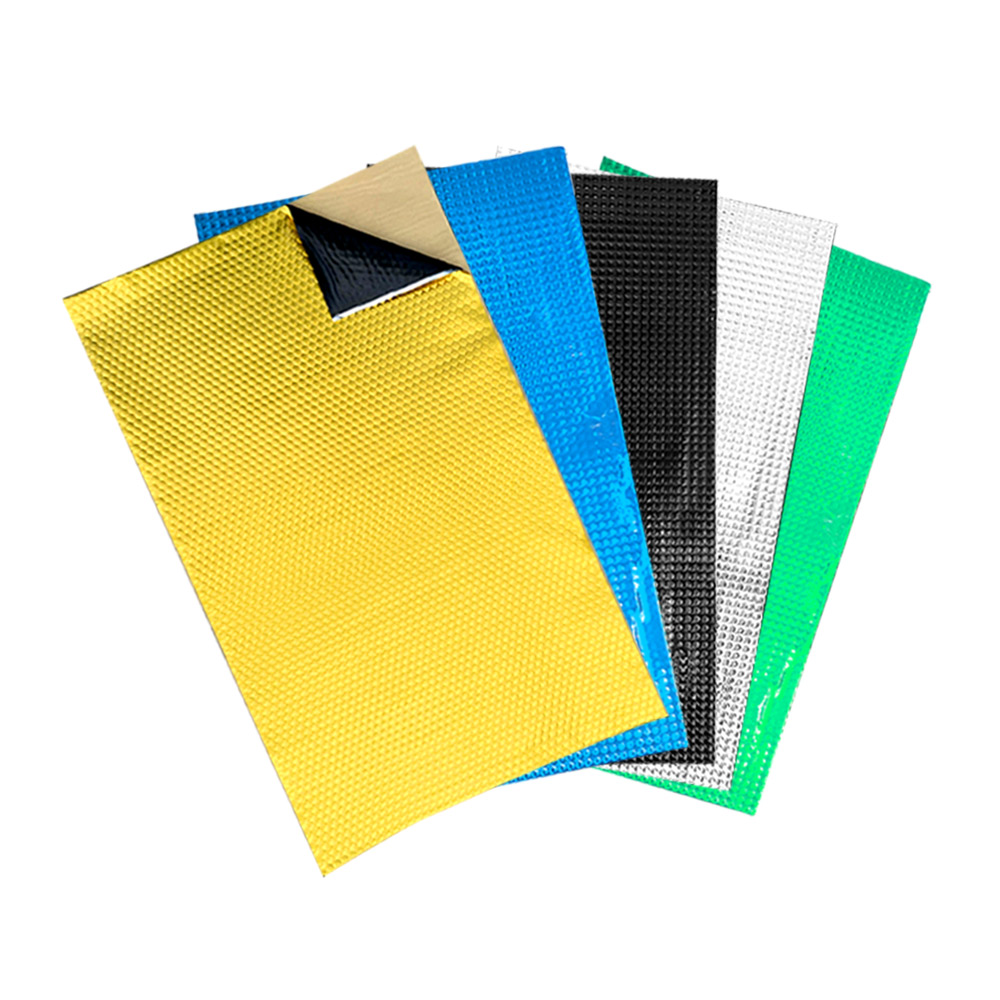

ASLONG Butyl Rubber Sound Damping Mat for sale. Effectively reduces noise and vibrations. High-quality butyl rubber ensures superior performance and durability. Ideal for automotive, industrial, and home applications.

The Butyl Rubber Sound Damping Mat is a flexible butyl rubber sheet designed to reduce structure-borne noise and panel resonance. It combines mass, damping, and adhesion to convert vibrational energy into heat and to add a barrier to airborne sound. This article compares butyl damping mats to other soundproofing materials to help you choose the right solution for your project.

How a butyl rubber sheet works: principles and benefits

Butyl rubber sheets work primarily by supplying constrained-layer damping and mass. When bonded to a vibrating panel (for example, a car door, a machine housing, or a metal wall), the viscoelastic butyl layer dissipates vibrational energy. The damping reduces amplitude of resonant peaks, while the added mass helps block airborne sound transmission.

Key practical benefits:

- Excellent vibration damping at mid and low frequencies where panels resonate.

- Long-term adhesion and weather resistance compared with some organic foams.

- Thin profile with high performance—useful when space is limited.

- Durable for automotive and industrial environments with temperature and chemical resistance.

Common soundproofing materials: quick overview

To assess where butyl excels, it helps to understand other common materials you'll encounter:

- Mass-Loaded Vinyl (MLV): dense flexible barrier for blocking airborne sound.

- Acoustic foam (open-cell polyurethane): reduces echo and mid-high frequency airborne sound absorption, minimal mass.

- Fiberglass or mineral wool: fibrous absorbers for airborne noise inside cavities; good for high-frequency sound control and improving STC when combined with mass barriers.

- Bitumen/Asphalt damping sheets: traditional automotive damping material, heavier and sometimes less flexible than butyl.

- Butyl Rubber Sound Damping Mat: combines damping and some mass; optimized for reducing panel vibration and structure-borne noise.

Performance comparison table: butyl rubber mat vs other materials

The table below gives practical, approximate comparisons across key parameters important for selection. Values are indicative ranges based on typical product data and industry references; actual performance depends on thickness, application method, and assembly design.

| Property | Butyl Rubber Sound Damping Mat | Mass-Loaded Vinyl (MLV) | Acoustic Foam (Open-cell) | Fiberglass / Mineral Wool | Bitumen Damping Sheets |

|---|---|---|---|---|---|

| Primary function | Damping/vibration control + moderate mass | Airborne sound barrier (high mass) | Echo reduction, high-frequency absorption | Airborne absorption in cavities | Damping, vibration control (traditional) |

| Typical thickness (mm) | 1.5 - 4 | 2 - 6 | 10 - 50 | 25 - 100 | 1.5 - 5 |

| Effect on structure-borne noise | High (5 - 12 dB typical improvement on resonant panels) | Low (mainly blocks airborne) | Low | Low to moderate | Moderate (often 3 - 8 dB) |

| Effect on airborne noise | Moderate (adds mass, best combined with barrier) | High (10 - 20 dB depending on installation) | Moderate at mid-high frequencies | Good at mid-high when thick | Moderate |

| Durability & environmental resistance | High (good temperature and moisture resistance) | High | Low (degrades with moisture) | Moderate (can absorb moisture if not protected) | Moderate to high |

| Ease of installation | Easy (peel-and-stick options available) | Moderate (heavy, needs sealing) | Easy (adhesive or panels) | Moderate (cuts and fits, requires vapor barrier) | Moderate (adhesive activation often required) |

| Typical cost | Medium | High | Low - Medium | Low - Medium | Low - Medium |

When to choose butyl rubber sheet over other options

Choose a butyl rubber sheet when the problem is panel resonance, machinery vibration, or when you need high damping in a thin form factor. Common scenarios:

- Automotive: door skins, trunk lids, floor pans—reduces road noise and rattles.

- Industrial equipment: machine enclosures, HVAC panels—reduces tonal and broadband vibration noise.

- Appliance and electronics chassis: reduce buzzing and improve perceived quality.

Butyl mats are often combined with MLV or insulation to form a layered system: damping layer + mass barrier + absorptive cavity fill achieves the best broad-spectrum reduction.

Installation guidance and best practices for optimal results

Good installation determines real-world performance. Follow these practical steps:

- Clean the surface thoroughly. Remove oils, rust, or paint flakes to ensure adhesion.

- Measure and cut the butyl sheet to fit the target area. Use overlap patterns to cover seams when necessary.

- Apply firm pressure; rollers are recommended to ensure full contact and remove trapped air.

- Use the correct thickness: thin mats for tight spaces, thicker for heavy panels and stronger damping.

- Combine with a barrier (MLV) or absorptive liner for airborne noise reduction.

- Allow for thermal expansion and avoid compressing butyl to extremes in high-heat zones without checking material specs.

Durability, maintenance and environmental considerations

Butyl rubber is known for its chemical stability and weather resistance compared with organic foams. Typical features:

- Resistance to aging, ozone, and moisture when properly formulated.

- Stable adhesion in typical automotive and industrial temperature ranges; check manufacturer temperature limits for extreme environments.

- Low maintenance after installation; inspect seals and overlaps periodically in harsh conditions.

Cost and lifecycle: is butyl a cost-effective choice?

While per-unit cost for butyl damping mats is generally mid-range, lifecycle value is high because of improved durability and reduced need for rework. Consider total system cost: combining a thin butyl mat with an MLV barrier often provides better performance at lower total thickness and less labor than multiple layers of heavy materials.

How to choose the right damping product: decision checklist

Use this checklist to choose among butyl mats and alternatives:

- Primary noise source: panel vibration vs airborne transmission?

- Available space and weight limits?

- Exposure to temperature, solvents, or humidity?

- Ease of installation and need for future service access?

- Budget and total lifecycle costs?

If structure-borne and resonant frequencies are the main issue, butyl damping mat is usually a top candidate. If airborne broadband noise is dominant and you can accept added weight, add MLV or heavier barriers.

Why choose ASLONG Butyl Rubber Sound Damping Mat

ASLONG's product is developed for high adhesion, consistent damping properties, and durability across automotive, industrial, and home applications. Key brand advantages include:

- Quality raw materials and controlled manufacturing for consistent damping performance.

- Available in various thicknesses and peel-and-stick versions for fast installation.

- Good balance of cost, durability, and performance versus traditional bitumen sheets and heavy barriers.

- Technical support and application guidance to optimize results for specific use cases.

Practical examples and common applications

Examples where ASLONG Butyl Rubber Sound Damping Mat delivers real benefits:

- Automotive doorpanels: eliminates buzzing at low frequencies and reduces road noise infiltration.

- Industrial enclosures: cuts tonal machine noise and reduces worker exposure to vibration noise.

- Home HVAC units and appliances: reduces mechanical noise and improves perceived product quality.

FAQ

Q: Can I use a butyl rubber mat alone to soundproof a room?

A: A single butyl mat is excellent at damping structure-borne noise and reducing panel resonance, but for full room soundproofing you usually need a combination: damping layer + mass barrier (like MLV) + cavity absorption (fiberglass or mineral wool) to address airborne and low-frequency sounds comprehensively.

Q: Is butyl rubber safe for use in vehicles?

A: Yes. Automotive-grade butyl damping mats are formulated to tolerate temperature cycles, resist aging, and avoid damaging vehicle coatings. Always choose automotive-rated products and follow installation guidance to avoid covering critical service areas or heat-sensitive components.

Q: How thick should the butyl sheet be for best results?

A: Thickness depends on the application. Thinner sheets (1.5-2 mm) work well for tight spaces and moderate damping. Thicker sheets (3-4 mm) provide higher damping and added mass for heavier panels. For extreme vibration problems, evaluate layered solutions.

Q: Do butyl mats smell or emit VOCs?

A: High-quality butyl formulations have low VOC emissions compared with some solvent-based adhesives. Choose products with manufacturer VOC data if indoor air quality is a concern.

Q: How do I maintain installed butyl damping mats?

A: Minimal maintenance is required. Inspect adhesion at edges and seams if exposed to moisture or high heat. Clean with mild detergent if accessibility is necessary; avoid aggressive solvents that could affect adhesion.

Contact and product access

After selecting the right solution, correct execution ensures effectiveness, making installation tips for maximum performance of Butyl Rubber Sound Mat essential.To evaluate ASLONG Butyl Rubber Sound Damping Mat for your project or request a quote, please contact our sales team or visit the product page. Sales email: sales@aslong-example.com (replace with actual address) or call your regional distributor. If you prefer, request a sample to check fit and performance before a full roll purchase.

Authoritative references and further reading

For more technical background and standards referenced in industry discussions, see the following authoritative sources:

- Butyl rubber – Wikipedia: https://en.wikipedia.org/wiki/Butyl_rubber

- Soundproofing – Wikipedia: https://en.wikipedia.org/wiki/Soundproofing

- Mass-loaded vinyl – Wikipedia: https://en.wikipedia.org/wiki/Mass-loaded_vinyl

- Damping (mechanics) – Wikipedia: https://en.wikipedia.org/wiki/Damping_(mechanics)

- Acoustic insulation overview – Wikipedia: https://en.wikipedia.org/wiki/Insulation#Acoustic_insulation

These sources provide background on material properties and the physics of sound control. For product-specific technical data, consult ASLONG's technical datasheets and installation guides.

What is Car Sound Insulation

The B2B Buyer’s Guide to egg crate foam roll | ASLONG Ultimate Insights

Testing Standards and Certification for Car Sound Damping Sheets

How to Choose Automotive Sound Insulation Materials in 2026

FAQs

How to customize products that meet the needs of my industry?

You only need to contact our sales or technical team, we will conduct an in-depth analysis based on your industry needs and provide tailor-made products and solutions. We guarantee to provide you with efficient and accurate services to meet your personalized requirements.

Do ASLONG's products meet environmental protection standards?

Yes, all ASLONG products comply with ISO14001 environmental management system certification and global environmental protection standards. We use environmentally friendly materials and are committed to providing sustainable solutions to help customers achieve green development goals.

Does ASLONG provide after-sales service?

Yes, we provide a full range of after-sales services, including technical support, installation guidance, product maintenance and quality tracking, etc., to ensure that each project goes smoothly and continues to perform at its best.

What industries are the products provided by ASLONG suitable for?

ASLONG's products are suitable for multiple industries, including air conditioning and HVAC, construction and waterproofing, automobiles and transportation, home appliances and electronics, industrial equipment and machinery, etc. We provide customized solutions for each industry to meet different needs.

What specific functions can ASLONG's products provide?

Our products cover functions such as insulation, sound insulation, shock absorption, waterproofing and sealing, and are widely used in improving energy efficiency, reducing noise, controlling vibration, protecting equipment, etc., helping customers optimize engineering effects and improve user experience.

Butyl Rubber Sound Damping Mat

ASLONG Butyl Rubber Sound Damping Mat for sale. Effectively reduces noise and vibrations. High-quality butyl rubber ensures superior performance and durability. Ideal for automotive, industrial, and home applications.

Mass Loaded Vinyl

ASLONG Mass Loaded Vinyl for sale. Reduce noise pollution effectively with our high-quality, mass-loaded vinyl. Ideal for soundproofing walls, floors, and more. Buy now and experience the difference!

Egg Crate Foam

ASLONG Egg Crate Foam for sale. Lightweight, breathable, and comfortable, our egg crate foam provides superior support and pressure relief. Perfect for mattresses, cushions, cars, construction industry, KTV, factories, etc.

NBR Foam

ASLONG NBR Foam: Wholesale NBR foam solutions for diverse applications. High-quality, durable, and competitively priced. Contact us today for bulk orders.

Professional support at any time

If you have any comments or good suggestions, please leave us a message; later our professional staff will contact you as soon as possible.

© 2026 ASLONG All Rights Reserved. Privacy Policy | Terms and Conditions | Sitemap

Whatsapp: +8613242879341

ASLONG Global

ASLONG

Aslong_global