Installation tips for maximum performance of Butyl Rubber Sound Mat

- Installation tips for maximum performance of Butyl Rubber Sound Mat

- Why choose a butyl rubber sheet for sound damping?

- Understand the product and application goals (use keyword: butyl rubber sheet)

- Tools and materials checklist for installing Butyl Rubber Sound Damping Mat

- Surface preparation: the single most important step

- Measuring, cutting, and layout strategies

- Adhesion techniques: ensuring full contact

- Use of heat and conforming to complex shapes

- Seams, edges and sealing (use keyword: butyl rubber sheet)

- Thickness selection and placement: a quick comparison table

- Specific guidance: automotive, industrial, and home installations

- Automotive

- Industrial

- Home and building

- Testing the installation and quality checks

- Maintenance and longevity

- Troubleshooting common problems

- Why ASLONG Butyl Rubber Sound Damping Mat is a reliable choice (brand advantage)

- Frequently Asked Questions (FAQ)

- 1. What surfaces can I apply Butyl Rubber Sound Damping Mat to?

- 2. Do I need a primer for butyl rubber sheet installations?

- 3. Can I use the mat outdoors?

- 4. How much area will a roll cover?

- 5. Can I remove and re-use the mat?

- Contact us or view the product

- Authority references and further reading

Installation tips for maximum performance of Butyl Rubber Sound Mat

Why choose a butyl rubber sheet for sound damping?

Butyl rubber sheet products are widely used for sound and vibration control because they combine high damping capacity, long-term flexibility, and excellent adhesion when installed correctly. The Butyl Rubber Sound Damping Mat is designed to cut structure-borne vibration and reduce airborne noise transmission in automotive, industrial, and home environments. Proper installation maximizes these benefits and prevents common performance losses such as debonding, poor coverage, or trapped air pockets.

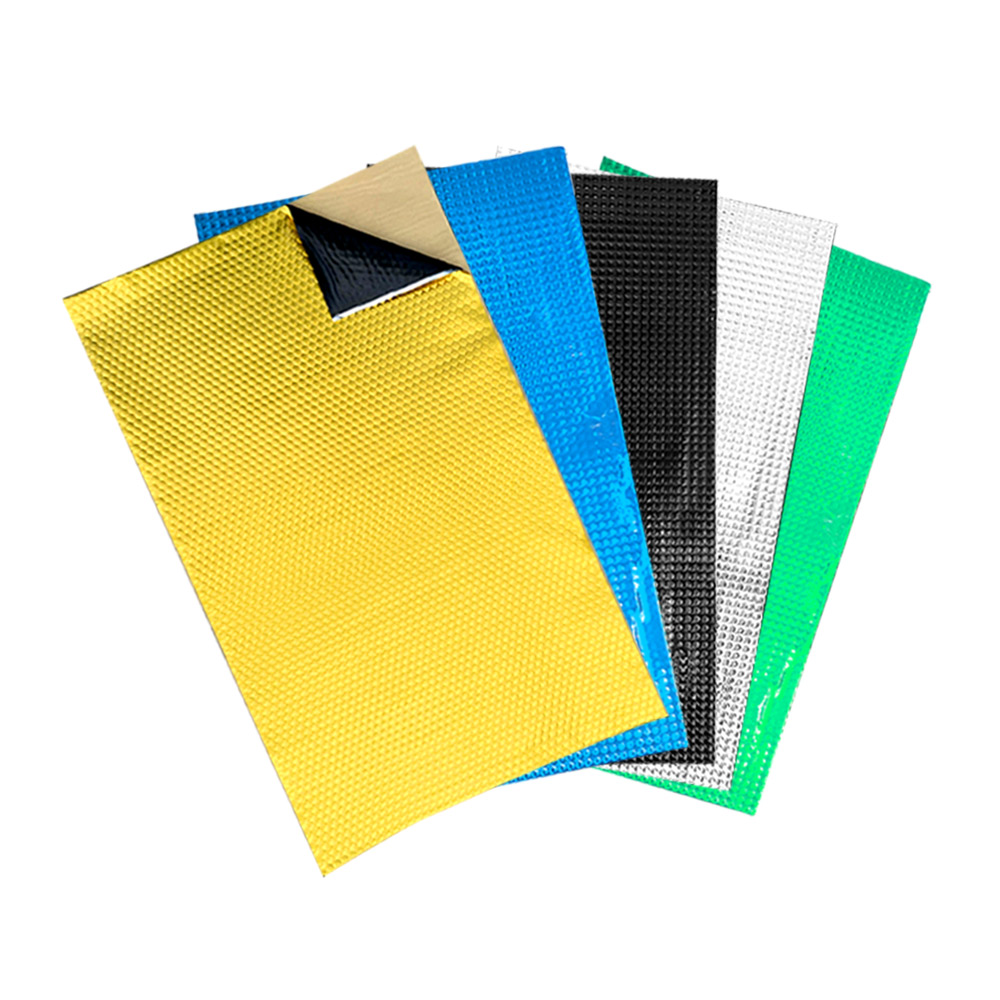

ASLONG Butyl Rubber Sound Damping Mat for sale. Effectively reduces noise and vibrations. High-quality butyl rubber ensures superior performance and durability. Ideal for automotive, industrial, and home applications. Beyond performance, responsible buyers also consider compliance and wellbeing, including the environmental and health safety of Butyl Rubber Sound Damping Mat.

Understand the product and application goals (use keyword: butyl rubber sheet)

Begin by clarifying the goals of your application. Are you reducing road noise in a vehicle, isolating a machine foundation, or damping resonance in a wall or ceiling? A well-placed butyl rubber sheet applied as a constrained layer or direct-mount damping layer must match the substrate, temperature range, and mechanical stresses of the installation. Knowing the target frequencies (low-frequency bass vs high-frequency rattles) will guide where to place thicker mats or multiple layers.

Tools and materials checklist for installing Butyl Rubber Sound Damping Mat

Prepare all tools and materials before starting. A typical toolkit includes:

- Butyl Rubber Sound Damping Mat (pre-cut sheets or roll)

- Isopropyl alcohol or dedicated degreaser

- Clean rags, wire brush, or scotch-brite pads

- Sharp utility knife or heavy-duty shears

- Measuring tape and marker

- Hand roller (3–5 kg) or weighted roller

- Heat gun or infrared heater (optional but recommended for cold conditions)

- Adhesive primer if installing on porous surfaces or after long-term exposure

- Sealant for seams and edges (acrylic or butyl-compatible sealant)

Having the right tools reduces installation time and ensures consistent adhesion and coverage.

Surface preparation: the single most important step

Cleanliness and surface condition determine long-term bond strength. Follow these steps:

- Remove paint flakes, rust, grease, and contaminants with a wire brush and solvent wipe.

- For automotive metal panels, remove insulation remnants and ensure surface is dry.

- For painted or powder-coated surfaces, abrade the area slightly to improve mechanical bite where recommended by the manufacturer.

- Use isopropyl alcohol to degrease and allow to dry—do not use water-based cleaners that leave residues.

Failing to prepare the substrate is the main cause of peeling or bubbling later.

Measuring, cutting, and layout strategies

Plan your layout before peeling any release liner. Measure twice and cut once. Tips:

- Cut slightly oversized pieces for full coverage near edges and trim back after tack down.

- Use templates for complex shapes. Cardboard or paper templates speed repeated cuts.

- Cut from the non-adhesive side where possible to avoid unnecessary contact.

- When working on multiple panels, stagger seams and avoid long straight seams that cross vibration paths.

Adhesion techniques: ensuring full contact

Butyl mats are typically self-adhesive, but technique matters:

- Initial tack-down: remove a small section of release liner and align the piece before full removal to avoid misplacement.

- Progressive application: peel the liner gradually while pressing the mat in place to prevent air pockets.

- Use a firm hand roller to apply uniform pressure across the mat, especially near edges and corners.

- For vertical or overhead installations, use temporary mechanical supports (tape or clamps) until the adhesive cures.

If the substrate is porous, or in cold conditions, apply a recommended primer to improve initial tack and long-term adhesion.

Use of heat and conforming to complex shapes

Butyl rubber becomes more pliable when warmed. Using a heat gun (at moderate temperature) provides these advantages:

- Improves conformability to compound curves and tight radii.

- Promotes better surface contact by lowering the material’s glass transition-like stiffness.

- Reduces risk of lifting in cold climates by enhancing initial tack.

Work in small sections and avoid overheating (which can deform the mat or affect adhesive). Heat until the mat is pliable, then press firmly and roll.

Seams, edges and sealing (use keyword: butyl rubber sheet)

Proper seam treatment maximizes performance and prevents ingress of moisture or dirt. Best practices:

- Overlap small seams slightly (2–3 mm) or butt them cleanly and seal with a butyl-compatible sealant.

- Treat exposed edges with edge sealant to prevent gradual peeling under thermal cycling.

- For multi-layer installations, stagger joints so that seams in consecutive layers do not align.

Using a second thin layer of butyl rubber sheet at edges improves durability where mechanical stress is expected.

Thickness selection and placement: a quick comparison table

Choosing thick vs thin mats depends on frequency targets and space constraints. The table below summarizes typical trade-offs.

| Thickness | Best for | Trade-offs |

|---|---|---|

| 1–2 mm | High-frequency rattles, interior panels, tight spaces | Limited low-frequency damping, lower mass |

| 2–4 mm | General automotive, door skins, moderate low-freq control | Good balance of mass and flexibility |

| 4–6+ mm | Floor pans, trunk lids, industrial machine bases for low-frequency control | Heavier, needs more space; best for structural vibration |

Specific guidance: automotive, industrial, and home installations

Different environments place different demands on installation:

Automotive

- Apply to inner door skins, roof panels, floor pans, and trunk lids at critical resonance zones.

- Prioritize larger coverage on door skins and floor areas to reduce road and wind noise.

- Keep heat-sensitive components and wiring accessible; avoid covering moving parts.

Industrial

- Use thicker mats on machine mounts and enclosures to reduce structure-borne noise.

- Combine with resilient mounts or mass layers for best low-frequency reduction.

- Consider chemical resistance and temperature limits; use primers if required by surface.

Home and building

- Apply behind drywall or under floors as part of sound isolation assemblies.

- Combine with insulation and air sealing to control both airborne and impact noise.

- Check building codes for fire and smoke requirements in occupied spaces.

Testing the installation and quality checks

Verify performance after installation to ensure long-term success:

- Visual inspection for full contact, no air bubbles, and properly sealed edges.

- Perform simple knock tests or use a phone-based decibel app to compare before/after.

- For professional validation, use accelerometers or sound level meters to measure vibration and dB reduction at targeted frequencies.

- Re-roll any areas that show incomplete adhesion and re-seal edges as needed.

Maintenance and longevity

Butyl rubber is durable but benefits from occasional checks:

- Inspect annually for edge lift, contamination, or punctures.

- Repair small failures with patch pieces and edge sealant.

- Avoid exposure to solvents or extended UV; when used externally, provide a protective overlay.

Troubleshooting common problems

Symptoms and fixes:

- Peeling: Improve surface prep, apply primer, increase roller pressure, or use edge sealant.

- Bubbling: Reheat and roll out bubbles; ensure substrate is dry and clean before reapplying.

- Poor low-frequency results: Add mass (thicker mat or additional constrained-layer mass) and ensure good coupling to the structure.

Why ASLONG Butyl Rubber Sound Damping Mat is a reliable choice (brand advantage)

ASLONG’s Butyl Rubber Sound Damping Mat is formulated for high damping efficiency and long-term adhesion. Key advantages:

- Consistent quality control ensures uniform thickness and adhesive performance.

- Designed for automotive-grade temperature and vibration cycles.

- Versatile formats: pre-cut sheets and rolls to suit DIY and production installations.

- Backed by product guidance and recommended installation practices for best performance.

Choosing ASLONG makes it easier to follow the installation practices outlined above and achieve measurable noise reduction results.

Frequently Asked Questions (FAQ)

1. What surfaces can I apply Butyl Rubber Sound Damping Mat to?

It adheres well to clean metal, painted metal (abrade first), composite panels, some plastics, and wood. Porous or contaminated surfaces should be primed or cleaned thoroughly.

2. Do I need a primer for butyl rubber sheet installations?

A primer is recommended for porous substrates, long storage conditions of parts, or low-temperature installs to ensure immediate tack and long-term bond.

3. Can I use the mat outdoors?

Butyl rubber resists moisture, but prolonged UV exposure can degrade the surface. Use a protective cover or paint layer for external applications.

4. How much area will a roll cover?

Coverage depends on roll dimensions. Check product specifications for square meters per roll. Allow extra material for overlaps and trimming.

5. Can I remove and re-use the mat?

Removal is possible but typically damages the adhesive surface. Re-use reduces adhesion and is not recommended for critical applications.

Contact us or view the product

For product specifications, pricing, or installation support for the Butyl Rubber Sound Damping Mat, contact our sales team or visit our product page. Our technicians can recommend the right thickness and format for your project and provide installation notes tailored to your application.

Authority references and further reading

Authoritative sources used for material properties and industry practices:

- Wikipedia — Soundproofing: https://en.wikipedia.org/wiki/Soundproofing

- ISO/ASTM standards summaries for vibration and sound testing (refer to official standards bodies for full text): https://www.iso.org/ and https://www.astm.org/

- Materials science references on butyl rubber: https://en.wikipedia.org/wiki/Butyl_rubber

- Industry best practices for vehicle NVH (Noise, Vibration, Harshness): manufacturer's technical bulletins and automotive NVH guides (search OEM and aftermarket technical resources)

These resources provide technical background on acoustic control principles, material properties, and testing methods that inform the installation recommendations above.

Best Affordable Automotive Sound Insulation Materials 2026

Best professional acoustic insulation material manufacturers and supplier brands

How to start the electrical materials supply business ?

Top 5 mass loaded vinyl sheet Company List and Products Compared

FAQs

Do ASLONG's products meet environmental protection standards?

Yes, all ASLONG products comply with ISO14001 environmental management system certification and global environmental protection standards. We use environmentally friendly materials and are committed to providing sustainable solutions to help customers achieve green development goals.

What specific functions can ASLONG's products provide?

Our products cover functions such as insulation, sound insulation, shock absorption, waterproofing and sealing, and are widely used in improving energy efficiency, reducing noise, controlling vibration, protecting equipment, etc., helping customers optimize engineering effects and improve user experience.

How to customize products that meet the needs of my industry?

You only need to contact our sales or technical team, we will conduct an in-depth analysis based on your industry needs and provide tailor-made products and solutions. We guarantee to provide you with efficient and accurate services to meet your personalized requirements.

Does ASLONG provide after-sales service?

Yes, we provide a full range of after-sales services, including technical support, installation guidance, product maintenance and quality tracking, etc., to ensure that each project goes smoothly and continues to perform at its best.

What industries are the products provided by ASLONG suitable for?

ASLONG's products are suitable for multiple industries, including air conditioning and HVAC, construction and waterproofing, automobiles and transportation, home appliances and electronics, industrial equipment and machinery, etc. We provide customized solutions for each industry to meet different needs.

Butyl Rubber Sound Damping Mat

ASLONG Butyl Rubber Sound Damping Mat for sale. Effectively reduces noise and vibrations. High-quality butyl rubber ensures superior performance and durability. Ideal for automotive, industrial, and home applications.

Mass Loaded Vinyl

ASLONG Mass Loaded Vinyl for sale. Reduce noise pollution effectively with our high-quality, mass-loaded vinyl. Ideal for soundproofing walls, floors, and more. Buy now and experience the difference!

Egg Crate Foam

ASLONG Egg Crate Foam for sale. Lightweight, breathable, and comfortable, our egg crate foam provides superior support and pressure relief. Perfect for mattresses, cushions, cars, construction industry, KTV, factories, etc.

NBR Foam

ASLONG NBR Foam: Wholesale NBR foam solutions for diverse applications. High-quality, durable, and competitively priced. Contact us today for bulk orders.

Professional support at any time

If you have any comments or good suggestions, please leave us a message; later our professional staff will contact you as soon as possible.

© 2026 ASLONG All Rights Reserved. Privacy Policy | Terms and Conditions | Sitemap

Whatsapp: +8613242879341

ASLONG Global

ASLONG

Aslong_global