Mass Loaded Vinyl vs Fiberglass Insulation: Which Wins?

- Mass Loaded Vinyl vs Fiberglass Insulation: Which Wins?

- Quick overview: what this guide will do for you

- What is Mass Loaded Vinyl (MLV)?

- What is Fiberglass Insulation?

- How do they control noise? (Absorption vs. Mass)

- Key comparison criteria

- Table: Side-by-side technical comparison

- Performance details: STC and NRC explained

- When Mass Loaded Vinyl is the better choice

- When Fiberglass Insulation is the better choice

- Combining MLV and Fiberglass: Best of both worlds

- Installation considerations and tips

- Installing MLV

- Installing Fiberglass

- Costs: what to expect

- Fire and moisture: safety and building code notes

- Practical project recommendations

- Real-world scenario examples

- Apartment shared wall with TV/voice complaints

- Home theater

- Floor between units

- Brand spotlight: ASLONG Mass Loaded Vinyl

- Installation checklist for buying MLV

- FAQ (Frequently Asked Questions)

- Q: Can I use only fiberglass to stop neighbors' loud music?

- Q: Is MLV safe for walls and ceilings?

- Q: Will adding MLV cause moisture problems?

- Q: Can I install MLV myself?

- Q: How much STC improvement can I expect?

- Contact & CTA

- References and further reading

Mass Loaded Vinyl vs Fiberglass Insulation: Which Wins?

Quick overview: what this guide will do for you

This article compares Mass Loaded Vinyl (MLV) and fiberglass insulation for soundproofing. We look at how each material performs across key criteria—sound transmission, absorption, installation ease, fire and moisture resistance, and cost—then provide real-world recommendations so you can decide which wins for your project. keyword: mass loaded vinyl.

What is Mass Loaded Vinyl (MLV)?

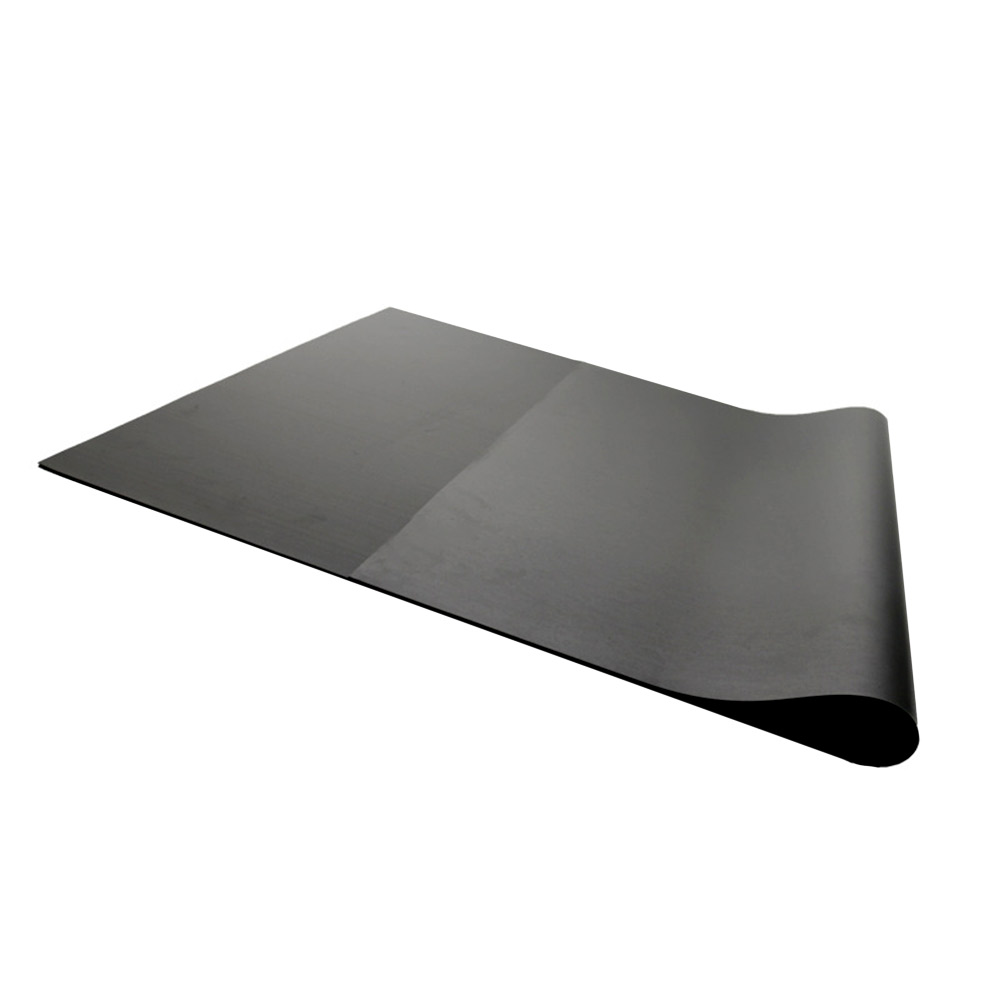

Mass Loaded Vinyl is a flexible, dense, relatively thin material manufactured specifically to add mass to walls, floors, ceilings, and doors to reduce airborne sound transmission. It relies on the mass law (more mass reduces transmission of airborne noise) to lower sound traveling between spaces. Mass Loaded Vinyl is commonly sold in rolls or sheets and is available in various surface weights (for example, 1 lb/ft², 2 lb/ft², etc.). keyword: mass loaded vinyl.

What is Fiberglass Insulation?

Fiberglass insulation is made from spun glass fibers formed into batts, rolls, or loose-fill. It is primarily a thermal insulation product, but because of its porous open-fiber structure, it also absorbs sound (especially mid-to-high frequencies). Fiberglass is often used in wall cavities, ceilings, and floor assemblies for both thermal and acoustic performance.

How do they control noise? (Absorption vs. Mass)

There are two key acoustic strategies:

- Absorption: Materials like fiberglass absorb sound energy and convert it to heat—effective for reducing reverberation and high-frequency noise within a room. Fiberglass excels here.

- Mass / Blocking: Materials like Mass Loaded Vinyl add mass and interrupt sound transmission paths, which effectively reduces airborne noise across a broad frequency range—especially lower frequencies. MLV excels at blocking.

In many real-world projects, combining both strategies (absorption + mass) yields the best results—for example, fiberglass in the stud cavity plus MLV applied to the drywall or floor.

Key comparison criteria

To help you choose, we compare MLV and fiberglass across measurable and practical dimensions: STC/NRC performance, density/weight, thickness and space needs, fire and moisture behavior, installation complexity, cost, and best-use scenarios. keyword: mass loaded vinyl.

Table: Side-by-side technical comparison

| Criteria | Mass Loaded Vinyl (MLV) | Fiberglass Insulation | Typical Source |

|---|---|---|---|

| Primary acoustic function | Sound blocking (adds mass) | Sound absorption (reduces reverberation) | Acoustical research/industry best practice |

| Typical density | ~1–2 lb/ft² (0.5–1 kg/m²) sheets; high mass per area | ~2–6 lb/ft³ (32–96 kg/m³) bulk density depending on product | Manufacturer datasheets |

| STC improvement when added to standard stud wall | +5 to +10 STC points (varies by assembly and MLV weight) | +1 to +3 STC points (as cavity fill only) | Field test reports; acoustical consultants |

| NRC (noise absorption) | Low (MLV is reflective/impermeable) | High (0.7–1.0 for thick batts/panels at mid-high freqs) | Acoustic lab measurements |

| Thickness needed | Thin (1/8–1/4 typical) but heavy | Thicker (2–6 typical) occupying cavity depth | Product specifications |

| Fire performance | Varies—many MLVs have flame-retardant additives; check rating | Non-combustible glass fibers, but faced products may vary | Building codes and datasheets |

| Moisture/mold risk | Impermeable barrier—can trap moisture if not detailed correctly | Can hold moisture if wet; glass fiber itself resists rot but facings and trapped moisture cause mold risk | Building science guidance |

| Installation complexity | Relatively easy to cut and fasten; seams must be sealed for best performance | Common trade install; fits cavities, but needs correct density and fill | Installer best practices |

| Typical cost (materials only) | Higher $/sqft than fiberglass | Lower $/sqft | Market prices (2024–2025 average) |

Table sources: manufacturer datasheets and acoustical guidance (see references below).

Performance details: STC and NRC explained

Understanding STC (Sound Transmission Class) and NRC (Noise Reduction Coefficient) helps you pick. STC measures how well an assembly blocks airborne sound between rooms. NRC measures how well a surface absorbs sound within a room. MLV boosts STC by adding mass to assemblies. Fiberglass improves NRC and helps reduce mid-to-high frequency noise but provides limited STC gains unless combined with other mass or isolation techniques.

When Mass Loaded Vinyl is the better choice

Use MLV when your primary problem is airborne noise transmission (voices, TV, music), especially at lower frequencies where mass matters. Typical scenarios:

- Shared walls in apartments where neighbors complain about sound transfer

- Floors between units where impact and airborne coupling are issues (use with underlayment for impact)

- Home theaters and recording studios where you need to block sound from leaving/entering

- Retrofit projects where you can't add thick cavity insulation or build out wall depth

Advantages: high blocking performance per thickness; thin profile for retrofits. keyword: mass loaded vinyl.

When Fiberglass Insulation is the better choice

Choose fiberglass when you need thermal insulation, want to reduce room reverberation, or have an available cavity to fill. It's effective in shared wall cavities to reduce mid-high frequency transmission, improves energy efficiency, and is cost-effective for large areas.

Advantages: low cost, dual thermal/acoustic benefits, established trade install practice. For best results in noise reduction, pair fiberglass with mass layers or resilient channels.

Combining MLV and Fiberglass: Best of both worlds

For many projects, the smart solution is combination:

- Install fiberglass in the stud cavity (absorb and dampen reflections).

- Add Mass Loaded Vinyl on the drywall face or between drywall layers to block remaining airborne sound.

This combo often yields the largest net STC improvement per dollar and per space, especially for retrofit situations where adding wall thickness is constrained.

Installation considerations and tips

Installing MLV

Key points for good MLV performance:

- Seal all seams and edges with acoustic caulk or foil tape—gaps reduce effectiveness.

- Fasten with screws and large washers or staples; avoid puncturing too many holes in one location.

- Consider layering MLV between two layers of drywall for greater STC improvement.

- Account for weight—architectural support may be necessary for ceilings or large spans.

Installing Fiberglass

Good fiberglass performance requires full, snug fill of cavities without compression. Use unfaced batts in retrofit situations where a vapor barrier is not desired, or faced batts where the wall assembly requires a vapor retarder. Proper installation avoids gaps and ensures the insulation performs thermally and acoustically.

Costs: what to expect

Material costs vary by region and product grade. As a general rule: fiberglass batts are the least expensive per square foot; MLV costs more per square foot but requires less thickness. Labor costs will depend on complexity—retrofitting walls with MLV (including sealing) can be more labor-intensive than installing batts in new construction cavities.

For a 10x12 room (approx. 480 sqft of wall area), rough material-only costs (2024–2025 approximate market averages): fiberglass batts: $100–$300; MLV (1 lb/ft²) roll covering same area: $600–$1,200. Prices vary—get local quotes. Source: market pricing summaries (see references).

Fire and moisture: safety and building code notes

Fiberglass glass fibers themselves are non-combustible, though facings and adjacent materials matter. MLV formulations vary—many are treated to meet flame-spread and smoke development requirements, but you must check manufacturer ratings and local building code requirements before installation, particularly in multi-family and commercial buildings.

Moisture: MLV is often impermeable and can act as a vapor barrier; improper use can trap moisture and lead to issues. Fiberglass does not feed mold but retains water if exposed; proper detailing and vapor management are essential in both cases.

Practical project recommendations

Which wins depends on your priority:

- If you prioritize blocking neighbor noise, low-frequency sound, or need a thin retrofit layer: choose Mass Loaded Vinyl.

- If you prioritize thermal performance, cost, and improving in-room acoustics: choose fiberglass insulation.

- If you need both: use fiberglass in the cavity plus MLV on the wall plane (or resilient channels + extra drywall) for a high-performance assembly.

Real-world scenario examples

Apartment shared wall with TV/voice complaints

Best approach: fiberglass in cavity + MLV on one or both sides of drywall. Expect STC improvements that make conversations and TV less intrusive. Sealing penetrations (electrical boxes, gaps) is crucial.

Home theater

Best approach: MLV on the wall and ceiling shell, resilient channels, double drywall, and absorption treatment (fiberglass panels) inside the room for internal acoustics. This combined approach addresses both transmission and internal sound quality.

Floor between units

Best approach: use appropriate underlayment with mass (MLV or specialized floor membranes) and cavity insulation below the floor. Impact isolation strategies are also needed for footsteps (floating floors, damping underlayment).

Brand spotlight: ASLONG Mass Loaded Vinyl

ASLONG Mass Loaded Vinyl for sale. Reduce noise pollution effectively with our high-quality, mass-loaded vinyl. Ideal for soundproofing walls, floors, and more. Buy now and experience the difference!

ASLONG Mass Loaded Vinyl is formulated to provide high mass per unit thickness, making it ideal for retrofit soundproofing where space is limited. Key brand advantages:

- Consistent mass density that performs to spec in blocking airborne noise.

- Flexible and easy-to-cut rolls for wall, floor, and ceiling applications.

- Available in multiple weights to match performance goals and budget.

- Quality control and datasheets to support code compliance and installer confidence.

For projects that need quick mass addition without increasing wall thickness significantly, ASLONG Mass Loaded Vinyl is an effective choice. keyword: Mass Loaded Vinyl.

Installation checklist for buying MLV

- Measure area and choose appropriate weight (heavier for more blocking).

- Verify fire ratings and product datasheet for your building type.

- Plan for seam sealing and transition details at edges, windows, doors, and electrical boxes.

- Consider combining with fiberglass or resilient channels for optimized results.

FAQ (Frequently Asked Questions)

Q: Can I use only fiberglass to stop neighbors' loud music?

A: Fiberglass helps reduce mid-high frequencies and internal room echo, but it provides limited blocking of low-frequency airborne noise. For loud music or deep bass, adding mass (MLV) or decoupling strategies will be much more effective.

Q: Is MLV safe for walls and ceilings?

A: Many MLV products include flame retardant additives, but ratings vary. Always check the manufacturer's fire-performance data and local code requirements before installation. Avoid covering ventilation paths and ensure proper support for ceiling installations due to weight.

Q: Will adding MLV cause moisture problems?

A: MLV is often impermeable and can act as a vapor barrier. In some climates or assemblies, that can trap moisture if not paired with correct vapor management. Consult building science guidance or a professional to detail vapor control correctly.

Q: Can I install MLV myself?

A: Yes—many homeowners install MLV themselves using standard tools. Key skills include measuring/cutting, fastening, and sealing seams. For ceilings or complex assemblies, consider professional installation.

Q: How much STC improvement can I expect?

A: Improvements vary widely based on assembly. Adding 1–2 lb/ft² MLV to a standard drywall-stud wall can add roughly 5–10 STC points if installed and sealed properly. Real results depend on flanking paths and overall assembly. Use a qualified acoustical consultant for precise predictions.

Contact & CTA

If you're ready to improve your space's sound control, check ASLONG's product offering and technical datasheets for specifications and installation guidance. For product details, pricing, or a custom recommendation, contact our sales team or view the product page to buy now and experience the difference. keyword: mass loaded vinyl.After reviewing the strengths and limitations of each material, you can return to Choosing the Right Mass Loaded Vinyl for Walls to make a precise decision for your wall soundproofing project.

References and further reading

- Mass Law and acoustical principles — Acoustical Society of America and common acoustics textbooks (e.g., Everest & Pohlmann).

- STC/NRC testing standards — ASTM E90 (laboratory measurement of airborne sound transmission loss) and ASTM C423 (sound absorption).

- Building Science Corporation — practical guidance on moisture control, vapor barriers, and assemblies: https://www.buildingscience.com/

- Manufacturer datasheets for Mass Loaded Vinyl and fiberglass insulation (example sources: ASLONG product documentation; Johns Manville; Owens Corning technical guides).

- Practical acoustics guides and retrofit case studies — Noise Control Engineering Journal and acoustical consultant reports.

For exact test values, ratings, and installation advice, always consult product datasheets and local building codes. Contact ASLONG for product specifications and ordering information.

Quality Control Tests to Request from Sound Insulation Cotton Vendors

Optimizing Building Acoustics with Mass Loaded Vinyl

How to manufacturing acoustic isolation material

Top benefits of Butyl Rubber Sound Damping Mat for noise control

FAQs

What industries are the products provided by ASLONG suitable for?

ASLONG's products are suitable for multiple industries, including air conditioning and HVAC, construction and waterproofing, automobiles and transportation, home appliances and electronics, industrial equipment and machinery, etc. We provide customized solutions for each industry to meet different needs.

How to customize products that meet the needs of my industry?

You only need to contact our sales or technical team, we will conduct an in-depth analysis based on your industry needs and provide tailor-made products and solutions. We guarantee to provide you with efficient and accurate services to meet your personalized requirements.

Does ASLONG provide after-sales service?

Yes, we provide a full range of after-sales services, including technical support, installation guidance, product maintenance and quality tracking, etc., to ensure that each project goes smoothly and continues to perform at its best.

Do ASLONG's products meet environmental protection standards?

Yes, all ASLONG products comply with ISO14001 environmental management system certification and global environmental protection standards. We use environmentally friendly materials and are committed to providing sustainable solutions to help customers achieve green development goals.

What specific functions can ASLONG's products provide?

Our products cover functions such as insulation, sound insulation, shock absorption, waterproofing and sealing, and are widely used in improving energy efficiency, reducing noise, controlling vibration, protecting equipment, etc., helping customers optimize engineering effects and improve user experience.

Butyl Rubber Sound Damping Mat

ASLONG Butyl Rubber Sound Damping Mat for sale. Effectively reduces noise and vibrations. High-quality butyl rubber ensures superior performance and durability. Ideal for automotive, industrial, and home applications.

Mass Loaded Vinyl

ASLONG Mass Loaded Vinyl for sale. Reduce noise pollution effectively with our high-quality, mass-loaded vinyl. Ideal for soundproofing walls, floors, and more. Buy now and experience the difference!

Egg Crate Foam

ASLONG Egg Crate Foam for sale. Lightweight, breathable, and comfortable, our egg crate foam provides superior support and pressure relief. Perfect for mattresses, cushions, cars, construction industry, KTV, factories, etc.

NBR Foam

ASLONG NBR Foam: Wholesale NBR foam solutions for diverse applications. High-quality, durable, and competitively priced. Contact us today for bulk orders.

Professional support at any time

If you have any comments or good suggestions, please leave us a message; later our professional staff will contact you as soon as possible.

© 2026 ASLONG All Rights Reserved. Privacy Policy | Terms and Conditions | Sitemap

Whatsapp: +8613242879341

ASLONG Global

ASLONG

Aslong_global