Top benefits of Butyl Rubber Sound Damping Mat for noise control

- Top benefits of Butyl Rubber Sound Damping Mat for noise control

- What is a butyl rubber sheet and the Butyl Rubber Sound Damping Mat?

- How the butyl rubber sheet works to control noise

- Benefit 1 — Superior vibration damping with butyl rubber sheet

- Benefit 2 — Broad frequency performance for real-world noise problems

- Benefit 3 — Durability, temperature resilience, and long service life

- Benefit 4 — Easy installation and adaptability of Butyl Rubber Sound Damping Mat

- Benefit 5 — Lightweight mass-loading compared to alternatives

- Benefit 6 — Versatility across automotive, industrial, and home applications

- Benefit 7 — Improved acoustic comfort and product quality perception

- Comparative performance: Butyl rubber sheet vs alternatives

- How to choose the right butyl rubber sheet for your application

- Practical installation tips for best results with butyl rubber sheet

- Measuring effectiveness — what to expect

- ASLONG Butyl Rubber Sound Damping Mat — brand advantages and why choose ASLONG

- Cost-effectiveness and lifecycle considerations for using butyl rubber sheet

- FAQ — Frequently Asked Questions (related to the Butyl Rubber Sound Damping Mat and butyl rubber sheet)

- Contact and view product — next steps

- References and authoritative resources

Top benefits of Butyl Rubber Sound Damping Mat for noise control

What is a butyl rubber sheet and the Butyl Rubber Sound Damping Mat?

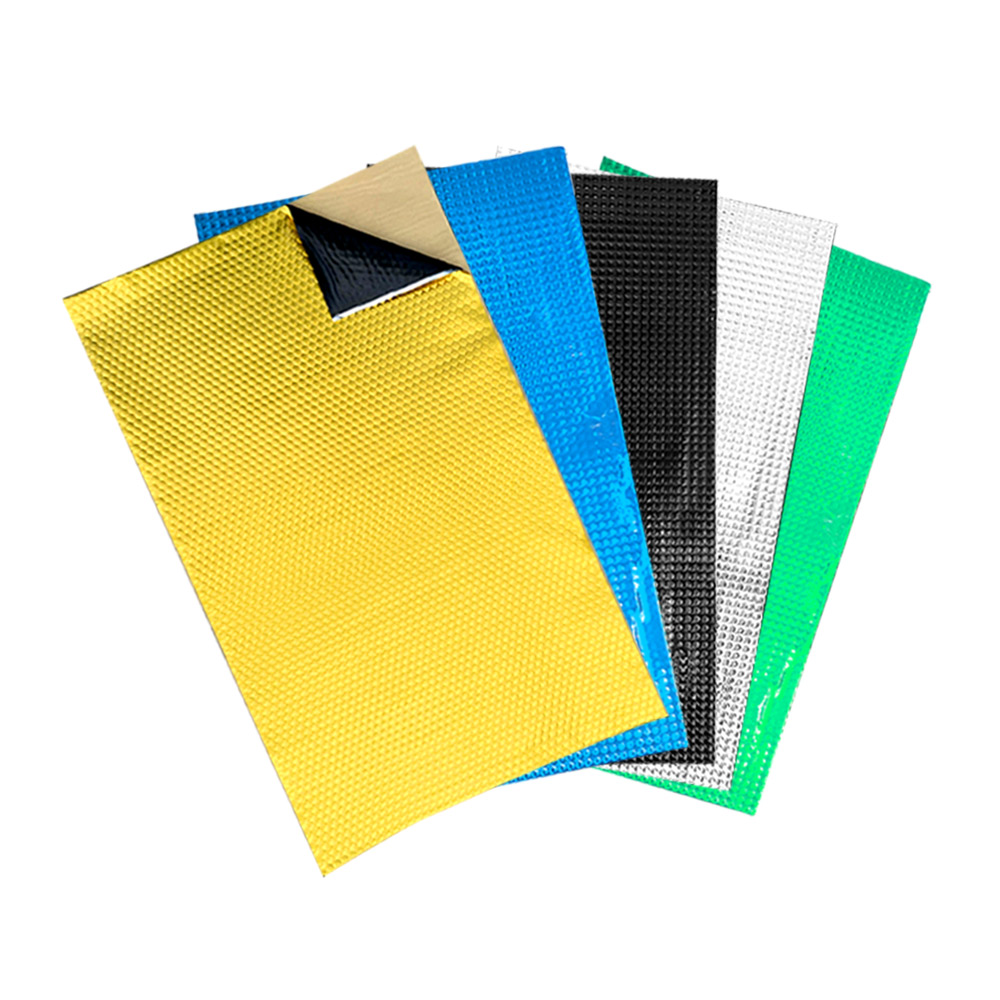

ASLONG Butyl Rubber Sound Damping Mat for sale. Effectively reduces noise and vibrations. High-quality butyl rubber ensures superior performance and durability. Ideal for automotive, industrial, and home applications.

A butyl rubber sheet is a dense, viscoelastic material engineered to absorb and dissipate vibrational energy. The Butyl Rubber Sound Damping Mat is a product built from high-grade butyl rubber designed specifically to reduce structure-borne noise and resonance in panels, floors, doors, and housings. The combination of mass, internal damping, and optional adhesive backing makes it an effective solution for many noise-control challenges.

After understanding the key advantages for noise control, many buyers explore the top reasons professionals choose Butyl Rubber Sound Damping Mat when selecting reliable soundproofing solutions.

How the butyl rubber sheet works to control noise

Butyl rubber sheet reduces noise primarily through two mechanisms: adding mass to a vibrating panel and converting vibrational energy into heat via internal friction (damping). When bonded to a metal or composite surface, the Butyl Rubber Sound Damping Mat raises the total mass and alters the panel's resonant behavior. More importantly, the viscoelastic nature of butyl rubber dissipates vibrational energy internally rather than allowing it to radiate as audible sound. This dual-action—mass loading plus internal damping—makes it particularly effective against structure-borne noise that is difficult to address with porous absorbers alone.

Benefit 1 — Superior vibration damping with butyl rubber sheet

High damping capacity is the core advantage of butyl rubber. Unlike simple mass-loaded barriers that rely only on added mass, a Butyl Rubber Sound Damping Mat reduces vibration amplitude through energy dissipation. This is crucial for reducing rattles, panel resonance, and tonal noise in automotive door skins, hoods, trunk lids, machine enclosures, and appliance panels. For users seeking quieter cabins or quieter machinery, the damping performance translates into a tangible reduction in perceived noise and improved sound quality.

Benefit 2 — Broad frequency performance for real-world noise problems

Butyl rubber sheet materials deliver meaningful attenuation across a wide frequency range, from low-frequency mechanical rumble to mid and high-frequency resonance peaks. This broadband performance is beneficial in mixed-noise environments—cars combine engine, road, wind, and structure-borne noise; industrial settings may have intermittent tonal machinery plus broadband background noise. The Butyl Rubber Sound Damping Mat is engineered to target multiple frequency bands, making it a practical, all-purpose damping treatment.

Benefit 3 — Durability, temperature resilience, and long service life

Butyl rubber is chemically stable, resistant to oxidation and many environmental stressors, and retains damping properties over long periods. Compared with cheaper asphalt-based mats that can dry out and become brittle, a high-quality butyl rubber sheet maintains flexibility and adhesion over a wider temperature range. For automotive and outdoor industrial applications, this durability reduces maintenance and replacement frequency—improving lifecycle cost-effectiveness.

Benefit 4 — Easy installation and adaptability of Butyl Rubber Sound Damping Mat

Commercial butyl rubber mats often come with a pressure-sensitive adhesive backing and can be cut to shape with simple tools. This makes installation straightforward for professionals and competent DIYers alike. The material conforms to irregular surfaces, allows layering for increased efficacy, and can be combined with foam absorbers where airborne noise control is required. The simplicity of installation reduces labor time and ensures consistent application—an important consideration for large-scale retrofits or production-line integration.

Benefit 5 — Lightweight mass-loading compared to alternatives

While mass contributes to sound reduction, adding large bulky mass can be impractical especially in automotive applications. Butyl rubber sheet delivers a favorable mass-to-performance ratio: it adds effective damping mass with less thickness and weight than alternatives that achieve similar results. This is especially relevant where weight matters—vehicles, aerospace components, and portable equipment benefit from acoustic treatments that do not significantly increase mass.

Benefit 6 — Versatility across automotive, industrial, and home applications

The Butyl Rubber Sound Damping Mat is suitable for numerous use cases: automotive door skins, trunks, floors, and wheel arches; industrial machinery panels, HVAC housings, and generator enclosures; and home appliances, HVAC ducts, and studio or home-theater panels. Its adaptability to different substrates (steel, aluminum, composites, and some plastics) and shapes makes it a universal choice for multi-industry noise-control projects.

Benefit 7 — Improved acoustic comfort and product quality perception

In consumer-facing products, quieter operation equates to perceived quality. In vehicles, for example, reduced panel vibration and cabin noise significantly improve perceived refinement. In industrial and home settings, lowered noise improves worker comfort, occupant satisfaction, and sometimes regulatory compliance. Using a butyl rubber sheet as part of a comprehensive acoustic strategy yields measurable improvements in both subjective comfort and objective sound measurements.

Comparative performance: Butyl rubber sheet vs alternatives

| Feature | Butyl Rubber Sheet (Butyl Mat) | Mass-Loaded Vinyl (MLV) | Asphalt-Based Damping Mat | Open-Cell Foam Absorber |

|---|---|---|---|---|

| Damping (structure-borne) | High — viscoelastic energy dissipation | Low — acts mainly as mass | Medium — initial good damping, may harden over time | Low — designed for airborne absorption |

| Airborne noise control | Moderate when combined with absorbers | High — adds mass to block sound | Moderate | High for mid/high frequencies |

| Durability / Aging | High — resists oxidation and creep | High | Lower — can dry and shrink over years | Varies — may sag or compress |

| Ease of installation | Easy (adhesive-backed) | Moderate (heavy sheets) | Easy | Easy |

| Weight considerations | Good balance — effective with modest weight | Heavier per unit area for equivalent blocking | Moderate | Light |

How to choose the right butyl rubber sheet for your application

Selecting the proper Butyl Rubber Sound Damping Mat requires attention to thickness, adhesive type, operating temperature, and backing options. Thicker mats generally provide better low-frequency damping but add more mass. Adhesive strength should match the substrate—high-tack adhesives for automotive metal panels, more removable adhesives for temporary installations. If exposure to high temperatures or solvents is expected, verify the butyl compound’s rated temperature range and chemical resistance. For combined airborne and structure-borne noise control, plan to pair the butyl mat with fibrous absorbers or a decoupling layer.

Practical installation tips for best results with butyl rubber sheet

1) Surface preparation: clean and degrease surfaces thoroughly; remove rust or loose paint. 2) Heating: gentle warming of the mat on cold days improves conformability and adhesive performance. 3) Proper placement: apply to the largest flat sections and around local vibration hot-spots (centers of panels, behind speakers, machine mounts). 4) Roller pressure: use a roller to ensure full contact and eliminate air pockets. 5) Layering: for stubborn resonance, use two thinner layers staggered to avoid seam alignment. These practices maximize the damping effect and ensure long-term adhesion.

Measuring effectiveness — what to expect

Performance depends on application and baseline conditions, but users commonly report perceptible reductions in tonal rattles and mid-frequency noise after applying butyl products. In laboratory settings, properly applied damping mats can reduce panel vibration by significant decibels at resonance frequencies; field results typically translate into lower subjective loudness and improved sound clarity. For objective assessment, measure before-and-after sound pressure levels (SPL) in the target area and consider using modal vibration measurements for panel-specific evaluation.

ASLONG Butyl Rubber Sound Damping Mat — brand advantages and why choose ASLONG

ASLONG’s Butyl Rubber Sound Damping Mat combines High Quality butyl compounds with factory-applied adhesive for consistent performance. Key brand advantages include strict quality control, long-term elasticity, and formulation optimized for automotive and industrial environments. ASLONG supports technical selection guidance, cutting-to-size options, and application recommendations—helping customers achieve predictable acoustic improvements while minimizing installation time and waste.

Cost-effectiveness and lifecycle considerations for using butyl rubber sheet

Although higher-quality butyl mats may carry a High Quality over basic asphalt sheets or some absorptive foams, the extended lifespan, superior damping efficiency, and reduced maintenance often yield lower total cost of ownership. In automotive manufacturing, lighter acoustic solutions can improve fuel efficiency; in industrial contexts, reduced acoustic maintenance and fewer replacement cycles lower operating costs. Evaluate the upfront material cost against expected service life and performance gains to quantify value.

FAQ — Frequently Asked Questions (related to the Butyl Rubber Sound Damping Mat and butyl rubber sheet)

Q: Is a butyl rubber sheet suitable for all substrates?

A: It adheres well to metals (steel, aluminum) and many composite panels. Adhesion to some plastics depends on surface energy—preparing the surface and selecting appropriate adhesive-backed variants is important.

Q: Can I use the Butyl Rubber Sound Damping Mat for airborne noise?

A: The mat is most effective for structure-borne noise and resonance. For airborne noise reduction, combine butyl damping mats with absorptive materials (fiberglass, foam) or mass barriers (MLV) for best results.

Q: How thick should the butyl mat be?

A: Typical thicknesses range from 1.5 mm up to 4 mm or more. Thicker mats improve low-frequency damping but add more mass—select based on the target frequency range and weight constraints.

Q: Will butyl mats degrade in hot climates?

A: High-quality butyl formulations resist high temperatures and UV exposure better than asphalt-based alternatives, but verify the product’s specified temperature range for extreme environments.

Q: Is installation reversible?

A: Some adhesive-backed butyl mats are designed for permanent bonding; others use removable adhesives for temporary applications. Choose a product variant that matches your need for permanence.

Contact and view product — next steps

To evaluate the right butyl rubber sheet solution for your project, contact ASLONG sales or technical support. You can also view product details and order samples at: /products/butyl-rubber-sound-damping-mat (use the provided slug to find the product page). Our team can recommend thickness, adhesive type, and application methods tailored to automotive, industrial, or residential needs.

References and authoritative resources

For further reading and standards-related information, see the following authoritative sources:

- Butyl rubber — Wikipedia: https://en.wikipedia.org/wiki/Butyl_rubber

- Soundproofing — Wikipedia: https://en.wikipedia.org/wiki/Soundproofing

- Acoustical Society of America (ASA) — Acoustics resources: https://acousticalsociety.org/

- ISO — Acoustics standards (overview): https://www.iso.org/ics/17.140/x/

- ASTM International — Sound transmission and measurement standards (e.g., ASTM E90 overview): https://www.astm.org/Standards/e90.htm

We recommend following recognized measurement standards (ASTM/ISO) when quantifying acoustic improvements to ensure comparable and reliable results.

Best professional sound deadening material for car manufacturers and supplier brands

Wholesale mass loaded vinyl manufacturer and supplier

Installation Methods and Bonding Options for Butyl Damping Mats

Wholesale acoustic fabric material manufacturer and supplier in China

FAQs

What industries are the products provided by ASLONG suitable for?

ASLONG's products are suitable for multiple industries, including air conditioning and HVAC, construction and waterproofing, automobiles and transportation, home appliances and electronics, industrial equipment and machinery, etc. We provide customized solutions for each industry to meet different needs.

Do ASLONG's products meet environmental protection standards?

Yes, all ASLONG products comply with ISO14001 environmental management system certification and global environmental protection standards. We use environmentally friendly materials and are committed to providing sustainable solutions to help customers achieve green development goals.

Does ASLONG provide after-sales service?

Yes, we provide a full range of after-sales services, including technical support, installation guidance, product maintenance and quality tracking, etc., to ensure that each project goes smoothly and continues to perform at its best.

How to customize products that meet the needs of my industry?

You only need to contact our sales or technical team, we will conduct an in-depth analysis based on your industry needs and provide tailor-made products and solutions. We guarantee to provide you with efficient and accurate services to meet your personalized requirements.

What specific functions can ASLONG's products provide?

Our products cover functions such as insulation, sound insulation, shock absorption, waterproofing and sealing, and are widely used in improving energy efficiency, reducing noise, controlling vibration, protecting equipment, etc., helping customers optimize engineering effects and improve user experience.

Butyl Rubber Sound Damping Mat

ASLONG Butyl Rubber Sound Damping Mat for sale. Effectively reduces noise and vibrations. High-quality butyl rubber ensures superior performance and durability. Ideal for automotive, industrial, and home applications.

Mass Loaded Vinyl

ASLONG Mass Loaded Vinyl for sale. Reduce noise pollution effectively with our high-quality, mass-loaded vinyl. Ideal for soundproofing walls, floors, and more. Buy now and experience the difference!

Egg Crate Foam

ASLONG Egg Crate Foam for sale. Lightweight, breathable, and comfortable, our egg crate foam provides superior support and pressure relief. Perfect for mattresses, cushions, cars, construction industry, KTV, factories, etc.

NBR Foam

ASLONG NBR Foam: Wholesale NBR foam solutions for diverse applications. High-quality, durable, and competitively priced. Contact us today for bulk orders.

Professional support at any time

If you have any comments or good suggestions, please leave us a message; later our professional staff will contact you as soon as possible.

© 2026 ASLONG All Rights Reserved. Privacy Policy | Terms and Conditions | Sitemap

Whatsapp: +8613242879341

ASLONG Global

ASLONG

Aslong_global