Choosing the right thickness of Butyl Rubber Sheet for soundproofing

- Choosing the right thickness of Butyl Rubber Sheet for soundproofing

- Why choose butyl rubber sheet for soundproofing and vibration control

- How thickness affects the acoustic performance of a butyl rubber sheet

- Typical thickness options and performance comparison for butyl rubber sheet

- Choosing thickness by application: automotive, industrial, and home soundproofing

- Installation tips: how to get the best out of your Butyl Rubber Sound Damping Mat

- Effective combinations and materials pairing

- Cost, durability and maintenance considerations when buying Butyl Rubber Sound Damping Mat

- ASLONG Butyl Rubber Sound Damping Mat — product overview and advantages

- How to specify the right thickness: a step-by-step checklist

- Frequently Asked Questions (FAQ)

- Q: What thickness of butyl rubber sheet is best for car doors?

- Q: Will a thicker butyl mat always give better soundproofing?

- Q: Can I install butyl mats myself?

- Q: Are there temperature limits for butyl rubber sheets?

- Q: How do I compare products when buying Butyl Rubber Sound Damping Mat?

- Contact and product access

- Authoritative references and further reading

- Final recommendations

- References

Choosing the right thickness of Butyl Rubber Sheet for soundproofing

Why choose butyl rubber sheet for soundproofing and vibration control

Butyl rubber sheet is widely used for noise reduction and vibration damping because of its high damping capacity, flexibility, and durability. As a viscoelastic material it absorbs vibrational energy and converts it to small amounts of heat, reducing structure-borne noise. For customers searching for a high-performance material, the butyl rubber sheet and related products such as the Butyl Rubber Sound Damping Mat deliver solid results in vehicles, machines, HVAC systems, and residential walls and floors. Thickness selection is often part of a broader evaluation, prompting comparisons such as Butyl Rubber Sound Damping Mat vs other soundproofing materials.

How thickness affects the acoustic performance of a butyl rubber sheet

Thickness directly influences mass per unit area, damping behavior, and the frequency range where the material is most effective. Two physical principles matter most:

- Mass effect: increasing mass per unit area tends to reduce airborne sound transmission, especially at mid and high frequencies. This follows the general mass law of sound insulation, where adding mass improves transmission loss.

- Damping effect: thicker layers of viscoelastic butyl provide more internal friction and therefore better reduction of structure-borne vibrations and resonances, which often dominate at low frequencies.

In real-world applications, butyl rubber sheets do two jobs: they add effective mass and they damp vibrational energy. However, returns diminish with increasing thickness beyond a point. Choosing the optimal thickness balances weight, cost, ease of installation, and the specific frequency range you need to control.

Typical thickness options and performance comparison for butyl rubber sheet

Below is a practical comparison of common thicknesses used in sound damping mats. Densities and dB estimates are approximate and intended for planning; actual performance depends on substrate, installation, and frequency content of the noise source. For these calculations we assume a butyl rubber density of approximately 1200 kg/m3, which is typical for many butyl formulations.

| Thickness (mm) | Approx mass (kg/m2) | Practical damping role | Typical dB reduction range (single layer, approximate) | Recommended applications |

|---|---|---|---|---|

| 1 mm | ~1.2 kg/m2 | Minor mass add; useful as a surface damping layer | 1-3 dB at mid/high; limited low freq effect | Interior panels, lightweight appliance damping |

| 2 mm | ~2.4 kg/m2 | Good balance of mass and damping | 2-6 dB across mid frequencies; improved vibration control | Automotive doors, trunk liners, equipment housings |

| 3 mm | ~3.6 kg/m2 | Stronger damping and mass effect, better low-mid control | 4-8 dB in mid; better performance at lower frequencies | Engine bays, heavy machinery panels, floors |

| 4-5 mm | ~4.8-6.0 kg/m2 | High damping; significant reduction of structure-borne noise | 5-10 dB depending on installation; substantial low freq improvement | Industrial enclosures, high-performance automotive soundproofing |

| 6 mm+ | >~7.2 kg/m2 | Maximized damping and mass; heavier and less flexible | 6-12 dB where properly installed; best for low frequency control | Specialist industrial applications, engine mounts, heavy vibration control |

Notes on table data: numbers are approximate guidelines. A single butyl layer will not fully eliminate transmission from a powerful source. For best results, pair butyl sheets with absorptive or decoupling layers and proper sealing.

Choosing thickness by application: automotive, industrial, and home soundproofing

Select thickness based on noise type, frequency content, space constraints, and weight limitations.

- Automotive: door skins, floors, and trunks commonly use 2-4 mm butyl rubber mats. 2 mm is popular where weight matters; 3-4 mm is used for trunk floors and engine bay panels where stronger damping is needed.

- Industrial machinery: machinery panels and enclosures that transmit low-frequency vibration often need thicker mats in the 4-6 mm range or multi-layer systems combining butyl with foam or mass-loaded vinyl.

- Residential: for walls, ceilings and floors, 2-3 mm can reduce panel vibration and improve perceived quietness, but for airborne sound insulation combine butyl with mineral wool or resilient channels for full STC gains.

When specifying thickness for a particular project, ask whether the priority is blocking airborne sound (adds mass) or damping structure-borne vibration (damping). Butyl contributes to both, but the ideal thickness changes with the priority.

Installation tips: how to get the best out of your Butyl Rubber Sound Damping Mat

Installation technique affects performance as much as thickness. Use these practical tips when installing butyl rubber sheet or Butyl Rubber Sound Damping Mat:

- Surface preparation: clean, degrease, and dry the substrate. Good adhesion ensures vibration energy transfers into the damping layer instead of bypassing it.

- Adhesion and pressure: forceful adhesion with a roller improves contact and performance. Many butyl mats are self-adhesive, but pressure activation maximizes bond strength.

- Layering: for broader frequency control pair butyl with absorptive foam for mid-to-high frequencies, or with dense mass layers for more airborne transmission loss. Stagger seams and avoid gaps.

- Sealing edges: leave no gaps along joints; small gaps can create flanking paths that undermine damping.

- Temperature considerations: butyl remains flexible over a wide temperature range, but check manufacturer specs for extreme heat or cold exposure to avoid flow or embrittlement.

Effective combinations and materials pairing

Butyl works best as part of a system. Common combinations and their strengths are:

| Butyl pairing | Primary benefit | Typical use |

|---|---|---|

| Butyl + foam absorber | Reduces both structure-borne and airborne noise; foam absorbs reflected airborne noise | Vehicle interiors, equipment enclosures |

| Butyl + mass loaded vinyl (MLV) | High mass barrier for airborne noise; butyl damps panels backing the MLV | Walls, floors where high STC is required |

| Butyl + constrained layer (metal/foiled skin) | Constrained layer damping yields superior vibrational energy dissipation | Automotive skins, machinery housings |

Cost, durability and maintenance considerations when buying Butyl Rubber Sound Damping Mat

Thickness affects cost primarily through raw materials and shipping weight. Heavier mats cost more per square meter and may require more labor for installation. Durability is usually excellent: butyl resists aging, ozone, and many chemicals better than natural rubber. Consider these factors:

- Longevity: properly installed butyl mats last many years with minimal maintenance.

- Weight constraints: for vehicles and portable equipment prefer thinner mats where possible to balance mass and fuel economy.

- Fire and thermal: check product safety data for temperature limits and flammability ratings. In some industrial contexts fire-rated solutions may be required.

- Recyclability: butyl rubber is not as widely recycled as some thermoplastics; check local programs or manufacturer take-back options.

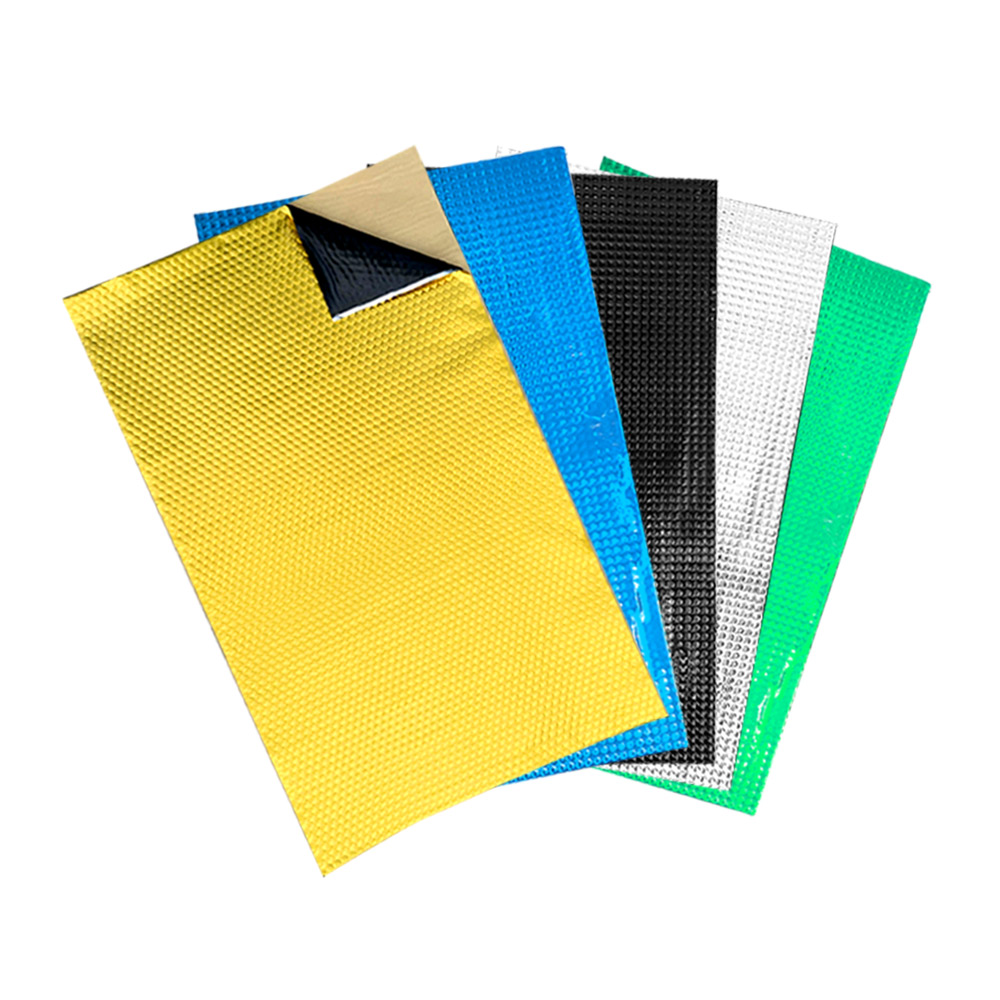

ASLONG Butyl Rubber Sound Damping Mat — product overview and advantages

ASLONG Butyl Rubber Sound Damping Mat for sale. Effectively reduces noise and vibrations. High-quality butyl rubber ensures superior performance and durability. Ideal for automotive, industrial, and home applications.

ASLONG Butyl Rubber Sound Damping Mat is formulated to provide consistent damping with good adhesion and flexibility. Typical advantages include:

- Multiple thickness options to match application needs from lightweight interior damping to heavy-duty industrial control

- High-quality butyl base for long-term elasticity and resistance to environmental degradation

- Ease of installation with self-adhesive backing on many product variants

- Compatibility with common aftermarket soundproofing combinations such as foam or MLV

When evaluating suppliers, look for clear technical datasheets that list density, recommended service temperature, peel adhesion, and test data for transmission loss or damping where available.

How to specify the right thickness: a step-by-step checklist

Follow this checklist to choose the correct butyl rubber sheet thickness for your project:

- Identify the dominant noise source and frequency range (engine/low-frequency vibration vs. mid/high airborne noise).

- Decide whether weight is a restricting factor (vehicles and portable equipment have strict limits).

- Select a base thickness: 2 mm for general automotive, 3-4 mm where stronger damping needed, 4-6 mm for heavy industrial vibration control.

- Plan complementary layers such as absorptive foam or mass barriers to address frequency bands where butyl is less effective alone.

- Request product datasheets and, where possible, third-party test data or case studies from the supplier.

Frequently Asked Questions (FAQ)

Q: What thickness of butyl rubber sheet is best for car doors?

A: Typically 2-3 mm is optimal for car doors balancing weight and damping. For additional low-frequency control use 3 mm or pair 2 mm butyl with a thin foam absorber.

Q: Will a thicker butyl mat always give better soundproofing?

A: Not always. Thicker gives more mass and damping but with diminishing returns. Installation quality and proper pairing with absorptive or mass layers often have equal or greater impact.

Q: Can I install butyl mats myself?

A: Yes. Many butyl mats are designed for DIY with self-adhesive backing. Ensure surfaces are clean and use a roller to press the mat firmly for best adhesion.

Q: Are there temperature limits for butyl rubber sheets?

A: Butyl performs well across a wide range of temperatures, but check the manufacturer datasheet for extremes. High continuous temperatures may soften some formulations.

Q: How do I compare products when buying Butyl Rubber Sound Damping Mat?

A: Compare density, thickness options, peel adhesion, recommended service temperature, and any acoustic test results. Also consider warranty and supplier support.

Contact and product access

To see product specifications or discuss the right thickness for your project, contact our sales team or visit the product page. For ASLONG Butyl Rubber Sound Damping Mat and technical support, contact us at: sales@example.com or view product details at https://www.aslong.com/product/butyl-rubber-sound-damping-mat.

Authoritative references and further reading

For technical background on butyl rubber and soundproofing principles, consult the following authoritative sources:

- Butyl rubber - Wikipedia

- Sound insulation - Wikipedia

- Mass law (acoustics) - Wikipedia

- Acoustical Society of America

Final recommendations

Choosing the right thickness of butyl rubber sheet is a balance among acoustic goals, weight, cost and installation constraints. For most automotive uses a 2-3 mm Butyl Rubber Sound Damping Mat gives an excellent balance. For industrial or low-frequency dominated problems, increase thickness to 4 mm or combine multiple layers. Always confirm product datasheets and request test data when specifying for mission-critical applications.

References

Sources used for general material and acoustic principles include the links listed above. For detailed product performance consult the ASLONG product literature and independent third-party acoustic testing where available.

Best professional acoustic insulation material manufacturers and supplier brands

Total Cost of Ownership: Evaluating Car Sound Damping Materials

NBR Foam for HVAC Noise Control: Applications and Tips

Mass Loaded Vinyl Noise Reduction for Apartments

FAQs

Do ASLONG's products meet environmental protection standards?

Yes, all ASLONG products comply with ISO14001 environmental management system certification and global environmental protection standards. We use environmentally friendly materials and are committed to providing sustainable solutions to help customers achieve green development goals.

What specific functions can ASLONG's products provide?

Our products cover functions such as insulation, sound insulation, shock absorption, waterproofing and sealing, and are widely used in improving energy efficiency, reducing noise, controlling vibration, protecting equipment, etc., helping customers optimize engineering effects and improve user experience.

Does ASLONG provide after-sales service?

Yes, we provide a full range of after-sales services, including technical support, installation guidance, product maintenance and quality tracking, etc., to ensure that each project goes smoothly and continues to perform at its best.

What industries are the products provided by ASLONG suitable for?

ASLONG's products are suitable for multiple industries, including air conditioning and HVAC, construction and waterproofing, automobiles and transportation, home appliances and electronics, industrial equipment and machinery, etc. We provide customized solutions for each industry to meet different needs.

How to customize products that meet the needs of my industry?

You only need to contact our sales or technical team, we will conduct an in-depth analysis based on your industry needs and provide tailor-made products and solutions. We guarantee to provide you with efficient and accurate services to meet your personalized requirements.

Butyl Rubber Sound Damping Mat

ASLONG Butyl Rubber Sound Damping Mat for sale. Effectively reduces noise and vibrations. High-quality butyl rubber ensures superior performance and durability. Ideal for automotive, industrial, and home applications.

Mass Loaded Vinyl

ASLONG Mass Loaded Vinyl for sale. Reduce noise pollution effectively with our high-quality, mass-loaded vinyl. Ideal for soundproofing walls, floors, and more. Buy now and experience the difference!

Egg Crate Foam

ASLONG Egg Crate Foam for sale. Lightweight, breathable, and comfortable, our egg crate foam provides superior support and pressure relief. Perfect for mattresses, cushions, cars, construction industry, KTV, factories, etc.

NBR Foam

ASLONG NBR Foam: Wholesale NBR foam solutions for diverse applications. High-quality, durable, and competitively priced. Contact us today for bulk orders.

Professional support at any time

If you have any comments or good suggestions, please leave us a message; later our professional staff will contact you as soon as possible.

© 2026 ASLONG All Rights Reserved. Privacy Policy | Terms and Conditions | Sitemap

Whatsapp: +8613242879341

ASLONG Global

ASLONG

Aslong_global