Selecting Car Sound Damping Material for Automotive OEMs

- Selecting Car Sound Damping Material for Automotive OEMs

- Why robust car sound damping material matters for automotive OEMs

- Understanding different types of car sound damping material

- Key material classes and typical applications of car sound damping material

- Performance metrics and testing standards for car sound damping material

- Useful metrics and what they tell you about a product

- Material properties, thickness and packaging considerations for OEM integration

- Thermal and chemical resistance expectations for car sound damping materials

- Installation methods and manufacturability of car sound damping material

- Common application issues and solutions

- Cost, weight and sustainability trade-offs for car sound damping material

- Quick comparison: typical trade-offs

- Quality control, durability and long-term performance

- Recommended QC checkpoints for incoming materials

- Side-by-side comparison: typical car sound damping material options

- Product highlight: Car Sound Damping Sheet for OEMs

- Why ASLONG Car Sound Damping Sheet suits automotive OEM requirements

- Procurement and specification checklist for OEM teams selecting car sound damping material

- Tips for pilot and validation phases

- FAQ - Frequently asked questions about car sound damping material

- Contact and view product

- References and authoritative resources

Selecting Car Sound Damping Material for Automotive OEMs

Why robust car sound damping material matters for automotive OEMs

Automotive OEMs face increasing expectations for cabin comfort, fuel efficiency, and regulatory compliance. Choosing the right car sound damping material is not just about quieter cabins: it affects vehicle weight, assembly speed, long-term durability, and cost of goods sold. Effective sound damping mitigates road and structure-borne noise, reduces panel vibration, and improves perceived quality—key differentiators in a crowded market.

Understanding different types of car sound damping material

OEM engineers and procurement teams must understand the major classes of damping materials and how they function. Common categories include viscoelastic damping sheets, closed-cell foam barriers, mass-loaded vinyl, and composite multi-layer assemblies. Each class targets specific noise paths: viscoelastic sheets convert vibration energy to heat, foam absorbs airborne energy, and mass-loaded layers add mass to block transmission. Selecting a material or combination depends on packaging space, target frequencies, thermal constraints, and production processes.

Key material classes and typical applications of car sound damping material

Below is a practical overview to guide initial selection:

| Material Type | Primary Mechanism | Best Use in Vehicle |

|---|---|---|

| Viscoelastic damping sheets | Dissipate vibration energy | Floor pans, doors, trunk lids |

| Closed-cell acoustic foam | Absorb airborne noise, reduce reverberation | Headliners, pillars, cavities |

| Mass-loaded barriers | Add mass to block sound transmission | Bulkheads, firewall, floor underlay |

| Composite sheets (damping + barrier) | Hybrid approach for low & middle frequencies | Under-dash, wheel arches |

Performance metrics and testing standards for car sound damping material

When evaluating car sound damping material, OEMs should focus on measurable acoustic and mechanical metrics. Relevant indicators include insertion loss or transmission loss in decibels (dB), dynamic stiffness, loss factor, and mass per unit area. Standards and test methods such as ASTM and ISO family procedures for sound transmission and material characterization provide repeatable results for supplier comparisons. Understanding how a material performs across frequency bands (e.g., low-frequency structure-borne noise vs. mid/high-frequency airborne noise) is essential to matching solutions to vehicle NVH targets.

Useful metrics and what they tell you about a product

Insertion loss quantifies how much noise a material reduces when applied. Dynamic stiffness and loss factor describe how well a material damps vibration. Mass per unit area impacts low-frequency blocking but influences vehicle mass. OEM specifications typically combine these criteria into pass/fail requirements or target curves that suppliers must meet during prototype and validation phases.

Material properties, thickness and packaging considerations for OEM integration

Beyond acoustic performance, material properties that affect manufacturing determine whether a product is suitable for high-volume OEM use. Key considerations include adhesive backing compatibility, conformability to stamped panels, temperature resistance during paint-bake cycles, and cut-to-shape or die-cut packaging to match assembly line stations. For automated application, consistent thickness and smooth release liners are critical. Lightweight multilayer systems can offer similar acoustic gains as heavy single-layer solutions with better mass efficiency.

Thermal and chemical resistance expectations for car sound damping materials

Materials must tolerate paint-oven temperatures, humidity, and automotive fluids without loss of adhesion or performance. Regulatory compliance for chemical content (e.g., REACH, RoHS) is increasingly required by OEM procurement teams. Selecting materials with proven thermal stability and documented compliance reduces validation risk and long-term warranty exposure.

Installation methods and manufacturability of car sound damping material

Installation approach influences cycle time and labor cost. Options include manual placement, semi-automated pick-and-place, and fully automated roll-on or press-apply systems. For high-volume OEMs, materials that allow repeatable, one-step application (self-adhesive sheets with strong initial tack) shorten line time. Consider also whether a product requires additional fasteners or surface primers. Good supplier support for die-cut patterns, application tooling, and training accelerates line integration.

Common application issues and solutions

Common problems are wrinkles, air entrapment, and poor edge adhesion. Solutions include specifying split liners for complex shapes, using heat-assist rollers for conformability, and validating adhesive performance across intended substrate coatings. Pre-qualified surface preparation procedures and process capability studies (Cp/Cpk) help reduce assembly variability.

Cost, weight and sustainability trade-offs for car sound damping material

OEM decision-making balances acoustic performance against cost, weight, and sustainability goals. Lightweight damping composites can deliver similar NVH improvements at lower mass, improving fuel economy or range for electric vehicles. However, higher-performance composites may carry greater raw material cost. Consider lifecycle impacts: recyclable or recycled-content materials may provide regulatory and corporate sustainability benefits. A total-cost-of-ownership view that includes tooling, line speed, warranty claims, and end-of-life considerations yields better long-term outcomes than selecting purely on unit price.

Quick comparison: typical trade-offs

| Factor | Low-cost single-layer | Advanced multilayer composite |

|---|---|---|

| Acoustic performance | Moderate | High (targeted freq. ranges) |

| Weight impact | Higher for same blocking | Optimized, lower mass |

| Manufacturing friendliness | Simple | Requires die-cutting, liners |

| Upfront cost | Lower | Higher but better ROI |

Quality control, durability and long-term performance

OEMs must validate that selected car sound damping material maintains properties over time and under environmental stressors. Accelerated aging tests—thermal cycling, humidity, salt spray, and UV exposure—simulate years of service. Monitoring adhesive retention, loss factor retention, and physical degradation ensures that cabin NVH remains within targets throughout the vehicle life. Supplier-provided aging data, batch traceability, and joint failure-mode analyses strengthen the OEM-supplier relationship.

Recommended QC checkpoints for incoming materials

Incoming inspection should include visual checks, dimensional verification, peel adhesion testing, and sample acoustic/structural damping tests. Implementing a supplier scorecard that tracks on-time delivery, nonconformance rate, and performance drift helps maintain supply stability.

Side-by-side comparison: typical car sound damping material options

The table below gives a pragmatic comparison to aid specification decisions. Performance ranges are indicative and should be validated with supplier test data tailored to your application.

| Option | Typical Insertion Loss Range | Typical Mass per Area | OEM Fit |

|---|---|---|---|

| Viscoelastic damping sheet | 2-6 dB (vibration damping) | 0.5-2 kg/m2 | High for panels and doors |

| Mass-loaded vinyl | 3-8 dB (low freq blocking) | 2-6 kg/m2 | Effective but heavier |

| Acoustic foam | 3-7 dB (mid-high freq absorb) | 0.1-0.8 kg/m2 | Excellent for cavities/headliner |

| Composite damping sheet | 4-10 dB (broadband) | 0.8-3 kg/m2 | Best balance performance/weight |

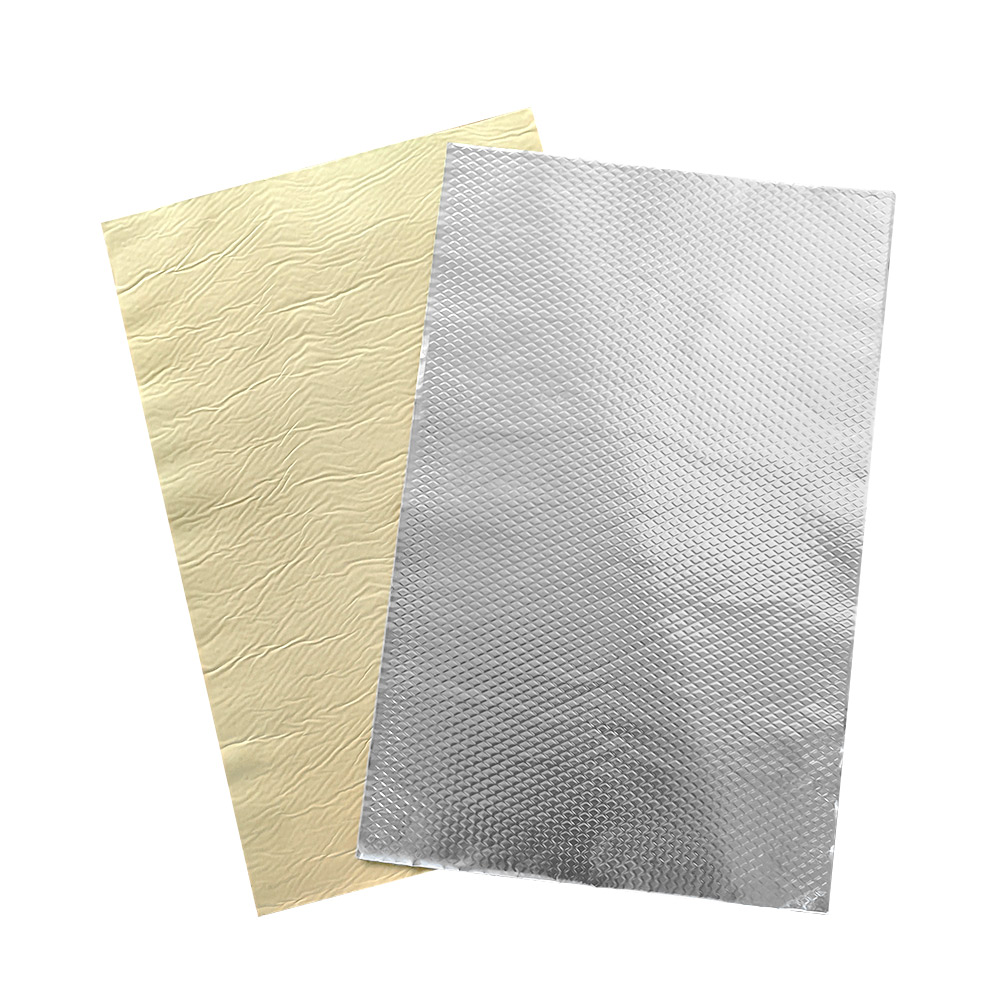

Product highlight: Car Sound Damping Sheet for OEMs

Discover the ASLONG Car Sound Damping Sheet—High Quality sound damping material designed to reduce road noise and vibration. Improve your driving comfort with this easy-to-install, durable car sound damping sheet for superior sound insulation.

Why ASLONG Car Sound Damping Sheet suits automotive OEM requirements

The ASLONG Car Sound Damping Sheet is engineered for high-volume manufacturing: it offers strong initial tack for fast application, consistent thickness for automated handling, and thermal stability compatible with paint-bake cycles. Its composite structure targets both structure-borne and airborne noise, giving OEMs a compact, lightweight solution that helps meet NVH targets without excessive mass addition. Supplier technical support for die-cutting, samples for NVH testing, and documented environmental compliance make it a pragmatic choice for program launches and mass production.

Procurement and specification checklist for OEM teams selecting car sound damping material

Use this checklist to define requirements that suppliers must meet before prototyping and validation:

- Target frequency bands and insertion loss targets (specify test method).

- Maximum allowable mass per vehicle and per area values.

- Adhesive performance: initial tack, peel strength, high/low temp retaining.

- Thermal resistance: paint-bake compatibility and continuous operating range.

- Die-cutting and liner requirements for assembly automation.

- Environmental compliance: REACH, RoHS, and documented VOC emissions if applicable.

- Aging test requirements: thermal cycling, humidity, salt spray, UV exposure.

- Supplier PPAP/PPF documentation and batch traceability requirements.

Tips for pilot and validation phases

Start with small-batch die-cut parts for fit and application trials. Conduct objective acoustic measurements on full vehicle prototypes and compare against control vehicles. Validate process capability on the assembly line and track first-pass yield. Early engagement with your supplier on tooling and logistics reduces program schedule risk.

FAQ - Frequently asked questions about car sound damping material

Q: What is the primary difference between damping and sound absorption?

A: Damping reduces vibration energy in structures (structure-borne noise), while absorption reduces airborne sound by converting sound energy to heat. Many OEM solutions combine both mechanisms for broadband performance.

Q: How much noise reduction can I expect from a damping sheet?

A: Typical real-world damping and composite solutions yield a few dB in specific frequency bands. Overall perceived improvement depends on vehicle baseline, targeted frequencies, and the combination of measures across the vehicle package.

Q: Can damping materials withstand paint-bake cycles?

A: High-quality automotive damping materials are formulated to tolerate typical paint-bake temperatures. Always verify supplier data for specific temperature and time profiles used in your process.

Q: Will adding damping materials significantly increase vehicle weight?

A: It depends on the chosen solution. Mass-loaded products add more mass, while optimized composites aim to deliver acoustic performance with minimal added weight. Evaluate mass per area against acoustic benefit to find the best trade-off.

Q: How should OEMs validate supplier claims?

A: Require supplier-provided test reports based on recognized standards, perform your own lab and full-vehicle acoustic tests, and validate durability with accelerated aging and environmental tests.

Contact and view product

Once OEM teams begin selecting car sound damping material for automotive OEMs, the next step is to objectively benchmark options by reviewing performance specs to compare car sound damping sheet buyers should focus on.To discuss specifications, request samples, or view technical datasheets for the ASLONG Car Sound Damping Sheet, contact our sales team or visit our product page. Our OEM support includes die-cutting, application guidance, and validation assistance to accelerate program timelines.

References and authoritative resources

For further reading and standards referenced in this guide, consult the following authoritative sources:

- World Health Organization - Environmental Noise Guidelines: https://www.who.int

- Acoustical Society of America - Fundamentals of Sound and Noise Control: https://acousticalsociety.org

- Wikipedia - Soundproofing (general overview): https://en.wikipedia.org/wiki/Soundproofing

- European Chemicals Agency (ECHA) - REACH: https://echa.europa.eu

- European Commission - RoHS: https://ec.europa.eu/environment/waste/rohs_eee/index_en.htm

- SAE International - Automotive NVH and standards: https://www.sae.org

These resources provide background on noise control principles, regulatory requirements, and industry guidance useful for validating and specifying car sound damping material for automotive OEM programs.

Noise Testing Methods for Automotive Insulation 2026

Ultimate Guide to Vehicle Sound Insulation Materials | ASLONG

What is Car Sound Insulation

Top 5 butyl rubber sound damping mat Company List and Products Compared

FAQs

Does ASLONG provide after-sales service?

Yes, we provide a full range of after-sales services, including technical support, installation guidance, product maintenance and quality tracking, etc., to ensure that each project goes smoothly and continues to perform at its best.

How to customize products that meet the needs of my industry?

You only need to contact our sales or technical team, we will conduct an in-depth analysis based on your industry needs and provide tailor-made products and solutions. We guarantee to provide you with efficient and accurate services to meet your personalized requirements.

Do ASLONG's products meet environmental protection standards?

Yes, all ASLONG products comply with ISO14001 environmental management system certification and global environmental protection standards. We use environmentally friendly materials and are committed to providing sustainable solutions to help customers achieve green development goals.

What industries are the products provided by ASLONG suitable for?

ASLONG's products are suitable for multiple industries, including air conditioning and HVAC, construction and waterproofing, automobiles and transportation, home appliances and electronics, industrial equipment and machinery, etc. We provide customized solutions for each industry to meet different needs.

What specific functions can ASLONG's products provide?

Our products cover functions such as insulation, sound insulation, shock absorption, waterproofing and sealing, and are widely used in improving energy efficiency, reducing noise, controlling vibration, protecting equipment, etc., helping customers optimize engineering effects and improve user experience.

Butyl Rubber Sound Damping Mat

ASLONG Butyl Rubber Sound Damping Mat for sale. Effectively reduces noise and vibrations. High-quality butyl rubber ensures superior performance and durability. Ideal for automotive, industrial, and home applications.

Mass Loaded Vinyl

ASLONG Mass Loaded Vinyl for sale. Reduce noise pollution effectively with our high-quality, mass-loaded vinyl. Ideal for soundproofing walls, floors, and more. Buy now and experience the difference!

Egg Crate Foam

ASLONG Egg Crate Foam for sale. Lightweight, breathable, and comfortable, our egg crate foam provides superior support and pressure relief. Perfect for mattresses, cushions, cars, construction industry, KTV, factories, etc.

NBR Foam

ASLONG NBR Foam: Wholesale NBR foam solutions for diverse applications. High-quality, durable, and competitively priced. Contact us today for bulk orders.

Professional support at any time

If you have any comments or good suggestions, please leave us a message; later our professional staff will contact you as soon as possible.

© 2026 ASLONG All Rights Reserved. Privacy Policy | Terms and Conditions | Sitemap

Whatsapp: +8613242879341

ASLONG Global

ASLONG

Aslong_global