Performance Specs to Compare: Car Sound Damping Sheet Buyers

- Performance Specs to Compare: Car Sound Damping Sheet Buyers

- Why car sound damping material matters for driving comfort

- Key specification: Density and material composition (car sound damping material)

- Thickness and coverage: How thickness affects performance

- Adhesion strength and ease of installation (: buy car sound damping material)

- Damping loss factor and frequency response: what engineers look for

- Measured noise reduction: STC, IIC and practical dB reductions

- Thermal and environmental specs: durability over seasons

- Weight per area and effect on fuel economy

- Comparing common specs — quick reference table

- How to validate manufacturer claims: testing and measurement tips

- Installation practices that influence spec outcomes (buy car sound damping material with good support)

- Cost, value and expected ROI for car sound damping sheet purchases

- Why choose ASLONG Car Sound Damping Sheet — product and brand advantages

- Real-world application strategy: where to apply damping sheets for biggest impact

- Environmental, safety and material handling considerations

- FAQs — Common buyer questions about car sound damping material and Car Sound Damping Sheet

- Contact/Buy CTA

- Authoritative references and further reading

Performance Specs to Compare: Car Sound Damping Sheet Buyers

Why car sound damping material matters for driving comfort

When shopping for a car sound damping material, buyers are not only buying quieter cabins — they are investing in improved ride comfort, reduced driver fatigue, and better audio performance. The right car sound damping material reduces road noise, engine vibration and panel resonance. This guide helps buyers compare the most relevant performance specifications so you can pick a Car Sound Damping Sheet that delivers real-world results. After understanding performance differences, procurement teams can formalize sourcing decisions using a structured procurement checklist for car sound damping sheet suppliers.

Key specification: Density and material composition (car sound damping material)

Density and composition determine how a sound damping sheet responds to vibrations and airborne noise. Heavier, viscoelastic layers typically increase damping at lower frequencies by converting vibrational energy into heat. Many automotive sheets use butyl rubber with aluminum foil, or asphalt-based composites. Compare the nominal density (grams per square meter or kg/m2) and base materials — higher density often increases low-frequency damping but may compromise fit and add weight. For buyers of car sound damping material, look for balanced density that improves damping without excessive weight.

Thickness and coverage: How thickness affects performance

Thickness is a simple spec that affects stiffness and the sheet's ability to kill panel resonance. Thicker sheets generally provide better damping for lower frequencies; thinner sheets are easier to conform to complex shapes and reach tight crevices. Consider the available thickness range (e.g., 1.5mm to 4mm) and packaged coverage area. Measure the square footage you plan to treat and choose a product with suitable thickness for the target panels (doors, floors, trunk lid, roof).

Adhesion strength and ease of installation (: buy car sound damping material)

Adhesion matters more than most buyers expect. A sheet with poor adhesive will lift over time and lose effectiveness. Look for peel strength values (commonly given in N/25mm) and service temperature range for the adhesive. User-focused features include pre-cut shapes, roll flexibility, and whether the adhesive is pressure-activated. If you plan to DIY, prioritize easy-to-handle sheets with strong initial tack and a clean peel liner — this reduces installation time and improves long-term performance.

Damping loss factor and frequency response: what engineers look for

Advanced buyers compare the damping loss factor (DLF) or loss modulus across frequency ranges. While manufacturers rarely publish full lab charts for every product, look for performance data showing how much vibration energy the material dissipates at frequencies relevant to automobiles (commonly 50–1000 Hz for structure-borne noise). A higher DLF in the engine and road-frequency bands indicates better real-world reduction of rumble and panel buzz.

Measured noise reduction: STC, IIC and practical dB reductions

Sound Transmission Class (STC) and Impact Insulation Class (IIC) are common in building acoustics but useful to understand conceptually. Automotive testing often reports dB reduction at targeted frequencies or overall cabin noise reduction. Typical high-quality car sound damping sheets can produce measurable cabin noise reductions of 1–4 dB when applied to key panels, and larger reductions in panel vibration and resonance. When comparing products, prefer those that provide test data with test setup details (panel type, mass, microphone placement) so you can compare apples to apples.

Thermal and environmental specs: durability over seasons

Automotive environments experience wide temperature swings and moisture. Check operating temperature ranges (e.g., -40°C to +120°C) and whether the material resists water, oil, and UV exposure. Long-term adhesive longevity and resistance to creep at high temperatures prevent sagging or detachment. For buyers of car sound damping material, pick products tested for automotive climates or that list automotive-grade certifications.

Weight per area and effect on fuel economy

Adding damping material increases vehicle mass. This is a trade-off between acoustic benefit and fuel efficiency. Weight is usually specified as g/m2 or kg per sheet. For full-vehicle treatments, lightweight but effective options minimize added mass while retaining damping performance. Consider targeted application (doors, floor, trunk) rather than full-coverage if weight is a concern.

Comparing common specs — quick reference table

Below is a comparison table illustrating typical spec differences across three representative car sound damping sheets. Use it as a template to evaluate actual data sheets from vendors. Numbers are illustrative and should be confirmed with manufacturer test reports.

| Spec | ASLONG Car Sound Damping Sheet | Competitor A (Butyl+Al foil) | Competitor B (Asphalt composite) |

|---|---|---|---|

| Thickness | 2.5 mm | 3.0 mm | 1.8 mm |

| Density | ~2.2 kg/m2 | ~2.5 kg/m2 | ~1.6 kg/m2 |

| Measured dB reduction (panel test) | 2–4 dB peak reduction | 1.5–3 dB | 1–2 dB |

| Adhesive peel strength | High (automotive grade) | High | Moderate |

| Temperature range | -40°C to +120°C | -30°C to +110°C | -20°C to +90°C |

| Ease of install | Good — flexible, pre-cut options | Fair — heavier | Good — thin but less adhesive |

How to validate manufacturer claims: testing and measurement tips

When a supplier provides performance data, verify the test conditions. Ask for: test method (ISO or ASTM reference), fixture details (panel material and thickness), microphone positions, and frequency bands analyzed. If possible, request sample pieces to test on a representative panel in your vehicle or work with a local acoustic lab for controlled measurements. DIY evaluation can use simple before/after measurements with the same microphone placement and engine/load conditions, focusing on perceived reduction and spectrum changes rather than absolute numbers.

Installation practices that influence spec outcomes (buy car sound damping material with good support)

Even the best car sound damping material will underperform if installed poorly. Surface preparation (cleaning, de-greasing), applying heat for improved adhesion on cold days, and proper roller pressure to eliminate air pockets are essential. For doors and irregular panels, trim or score the sheet to ensure full contact. Many manufacturers provide installation guidelines — choose a product that includes clear instructions or support to maximize real-world performance.

Cost, value and expected ROI for car sound damping sheet purchases

Price per square meter is only one part of the decision. Factor in coverage area, ease of installation (DIY vs. professional), and expected lifetime. A higher initial cost for better adhesion and performance can save money over time by avoiding rework or repeated purchases. For audio enthusiasts and drivers seeking comfort gains, targeted investments in doors and floor areas usually yield the best ROI.

Why choose ASLONG Car Sound Damping Sheet — product and brand advantages

ASLONG focuses on balanced performance, ease of installation, and long-term durability. The ASLONG Car Sound Damping Sheet is engineered as a high quality car sound damping material that reduces road noise and vibration while minimizing added weight. It is designed for DIY enthusiasts and professional installers, offering strong adhesive, vehicle-grade temperature tolerance and flexible application shapes.

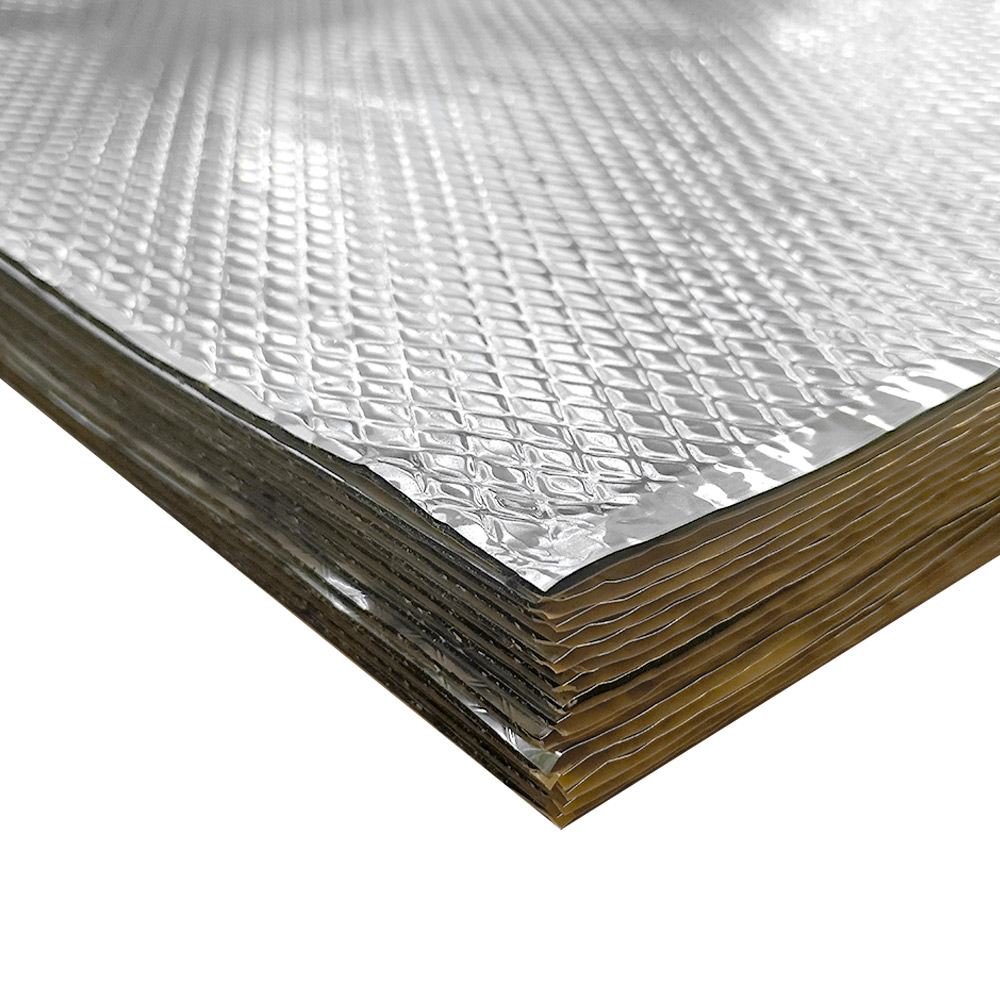

Product introduction:

Discover the ASLONG Car Sound Damping Sheet—High Quality sound damping material designed to reduce road noise and vibration. Improve your driving comfort with this easy-to-install, durable car sound damping sheet for superior sound insulation.

Real-world application strategy: where to apply damping sheets for biggest impact

Target panels that vibrate and radiate noise into the cabin: doors (large area, thin panels), floor (road noise paths), trunk lid and wheel arches. For audio systems, damping the doors and rear deck reduces panel resonance and improves loudspeaker performance. Use a combination of constrained-layer damping on panels and soft insulation for airborne noise to achieve a balanced result.

Environmental, safety and material handling considerations

Choose materials with low VOC emissions and stable chemistry across temperature extremes. Check for any handling precautions (e.g., nitrile gloves for sticky adhesives) and ensure proper disposal or recycling where possible. For professional installations, follow local workplace safety standards for heat guns and solvents.

FAQs — Common buyer questions about car sound damping material and Car Sound Damping Sheet

Q1: How much noise reduction can I expect after installing a Car Sound Damping Sheet?

A1: Expect measurable reductions typically in the 1–4 dB range for treated panels, with larger subjective improvements in perceived cabin quietness and a reduction in panel resonance. Results vary by vehicle, application area, and installation quality.

Q2: Can I install ASLONG Car Sound Damping Sheet myself?

A2: Yes. ASLONG sheets are designed for DIY installation with strong adhesive backing and flexible sheets. Follow surface prep guidelines, apply firm roller pressure, and use heat if necessary during cold weather.

Q3: Will damping material affect my car’s resale value?

A3: When installed neatly and professionally, damping materials can be a selling point for buyers who appreciate a quieter cabin. Poor installations that cause damage or visible mess can negatively affect value, so follow manufacturer instructions or use a professional installer if unsure.

Q4: Are there vehicle compatibility concerns?

A4: Most damping sheets work across a wide range of vehicles. Check thickness and flexibility if your vehicle has very tight cavities or very thin panels. ASLONG sheets offer flexible options suitable for most passenger cars.

Q5: How does damping interact with other insulation products?

A5: Damping sheets pair well with mass-loaded vinyl or foam-based absorbers. Use damping to reduce panel vibration (structure-borne noise) and soft absorbers for airborne noise to get a comprehensive reduction.

Contact/Buy CTA

Ready to improve your ride comfort? View the product page or contact our support team for advice on which ASLONG Car Sound Damping Sheet is right for your vehicle: View ASLONG Car Sound Damping Sheet • Contact customer service.

Authoritative references and further reading

These sources explain acoustics, NVH principles, and noise control fundamentals useful for evaluating technical claims:

What are the different types of sound insulation materials?

What is Sound Absorbing Cotton

Top reasons professionals choose Butyl Rubber Sound Damping Mat

What are the different types of airborne sound insulation materials?

FAQs

What specific functions can ASLONG's products provide?

Our products cover functions such as insulation, sound insulation, shock absorption, waterproofing and sealing, and are widely used in improving energy efficiency, reducing noise, controlling vibration, protecting equipment, etc., helping customers optimize engineering effects and improve user experience.

How to customize products that meet the needs of my industry?

You only need to contact our sales or technical team, we will conduct an in-depth analysis based on your industry needs and provide tailor-made products and solutions. We guarantee to provide you with efficient and accurate services to meet your personalized requirements.

Do ASLONG's products meet environmental protection standards?

Yes, all ASLONG products comply with ISO14001 environmental management system certification and global environmental protection standards. We use environmentally friendly materials and are committed to providing sustainable solutions to help customers achieve green development goals.

Does ASLONG provide after-sales service?

Yes, we provide a full range of after-sales services, including technical support, installation guidance, product maintenance and quality tracking, etc., to ensure that each project goes smoothly and continues to perform at its best.

What industries are the products provided by ASLONG suitable for?

ASLONG's products are suitable for multiple industries, including air conditioning and HVAC, construction and waterproofing, automobiles and transportation, home appliances and electronics, industrial equipment and machinery, etc. We provide customized solutions for each industry to meet different needs.

Butyl Rubber Sound Damping Mat

ASLONG Butyl Rubber Sound Damping Mat for sale. Effectively reduces noise and vibrations. High-quality butyl rubber ensures superior performance and durability. Ideal for automotive, industrial, and home applications.

Mass Loaded Vinyl

ASLONG Mass Loaded Vinyl for sale. Reduce noise pollution effectively with our high-quality, mass-loaded vinyl. Ideal for soundproofing walls, floors, and more. Buy now and experience the difference!

Egg Crate Foam

ASLONG Egg Crate Foam for sale. Lightweight, breathable, and comfortable, our egg crate foam provides superior support and pressure relief. Perfect for mattresses, cushions, cars, construction industry, KTV, factories, etc.

NBR Foam

ASLONG NBR Foam: Wholesale NBR foam solutions for diverse applications. High-quality, durable, and competitively priced. Contact us today for bulk orders.

Professional support at any time

If you have any comments or good suggestions, please leave us a message; later our professional staff will contact you as soon as possible.

© 2026 ASLONG All Rights Reserved. Privacy Policy | Terms and Conditions | Sitemap

Whatsapp: +8613242879341

ASLONG Global

ASLONG

Aslong_global