Procurement Checklist for Car Sound Damping Sheet Suppliers

- Procurement Checklist for Car Sound Damping Sheet Suppliers

- Why choose high-quality car sound damping material?

- Key technical specifications to verify for car sound damping material

- Quick comparison of common product grades

- Material composition and manufacturing standards

- Supply chain and manufacturing capacity considerations

- Quality assurance, testing, and traceability

- Commercial terms, pricing drivers and warranty

- Installation, packaging and after-sales support

- Procurement evaluation checklist (matrix)

- How ASLONG Car Sound Damping Sheet meets procurement needs

- Conclusion and next steps for procurement teams

- Frequently Asked Questions (FAQ)

- Q: What is the most important specification for a car sound damping sheet?

- Q: How do I compare prices between suppliers?

- Q: Are all damping sheets safe for painted surfaces?

- Q: What certifications should I insist on?

- Q: Can suppliers provide pre-cut kits for specific models?

- Contact and call to action

- Authoritative references

Procurement Checklist for Car Sound Damping Sheet Suppliers

Why choose high-quality car sound damping material?

Reducing road noise and vibration inside a vehicle improves perceived quality, driver comfort and even the life of interior components. When you buy Car Sound Damping Sheet you are investing in a component that directly affects NVH (noise, vibration, harshness) performance. Choosing the right supplier means verifying materials, manufacturing processes, test data, certifications and after-sales support so that the installed product meets your vehicle performance targets over the vehicle life cycle.

Product introduction:

Discover the ASLONG Car Sound Damping Sheet—High Quality sound damping material designed to reduce road noise and vibration. Improve your driving comfort with this easy-to-install, durable car sound damping sheet for superior sound insulation.

Key technical specifications to verify for car sound damping material

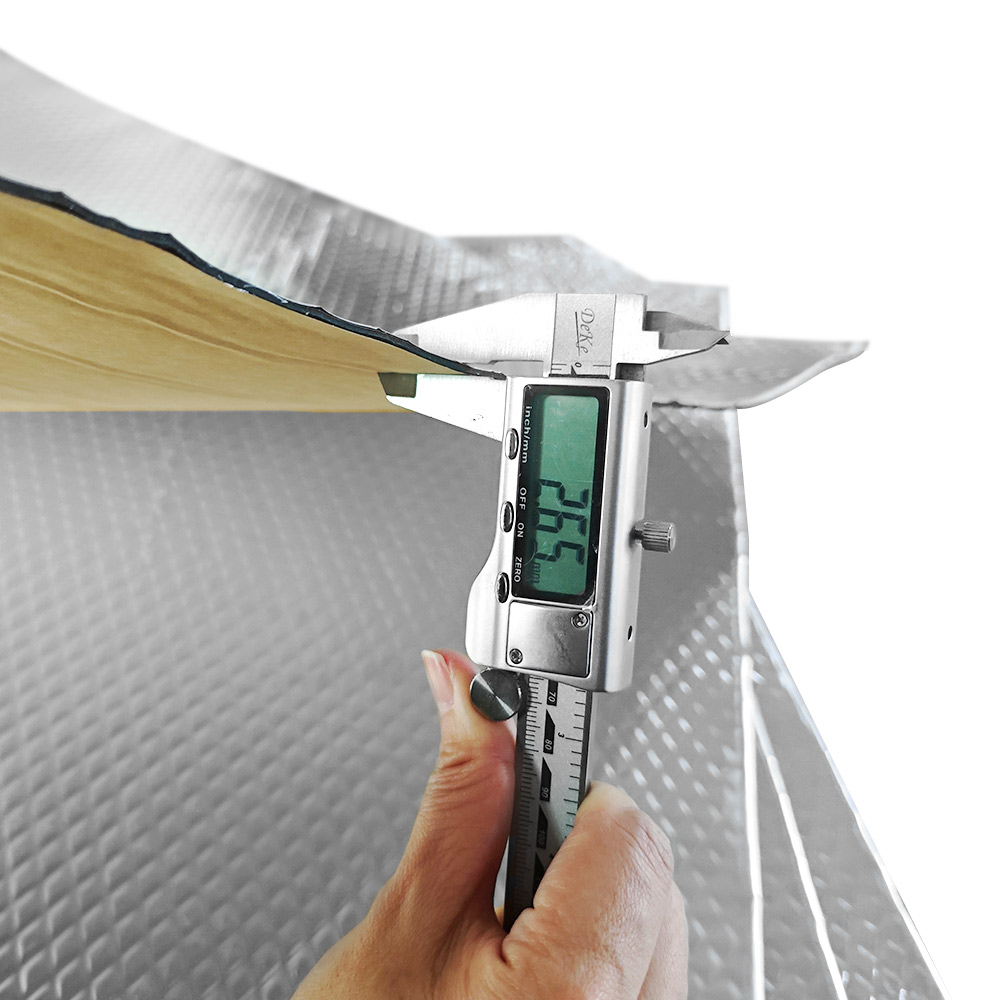

Before placing an order, request detailed technical data sheets and test reports. The most important technical parameters to confirm are mass per unit area, thickness, dynamic stiffness / damping factor, operating temperature range, surface adhesion strength, and flammability rating. These characteristics determine how effectively the sheet reduces structural vibrations and airborne noise in real-world conditions.

Typical specifications to request from suppliers:

- Material type: Butyl-based, polymer foam, asphalt-free composites, or hybrid materials.

- Thickness range: 1.5 mm to 5 mm (or custom thickness depending on application).

- Mass per area: grams per square meter (g/m2) or kg/m2.

- Damping properties: loss factor or transmission loss test results.

- Adhesive performance: peel strength (N/cm) and long-term adhesion at elevated temperatures.

- Operating temperature: minimum and maximum service temperatures (for climates and paint-bake cycles).

- Corrosion / chemical compatibility: whether the sheet is safe for painted surfaces and sheet metal.

- Flammability: UL94 classification or equivalent.

Quick comparison of common product grades

| Characteristic | Standard Grade | High Quality Automotive Grade | OEM Spec |

|---|---|---|---|

| Material | Butyl with foil | Butyl-polymer hybrid | Custom composite, low VOC |

| Typical thickness | 1.5-2 mm | 2-4 mm | 1.8-5 mm |

| Mass per area | 1200-1800 g/m2 | 1600-2500 g/m2 | Tailored to spec |

| Adhesion | Good | High temp stable | Measured to spec, high peel |

| Certifications | Basic test reports | IATF or ISO, chemical safety | Full OEM testing, UL/REACH/RoHS |

Material composition and manufacturing standards

Understanding the composition is essential. Butyl-based sheets provide high damping and strong adhesion, while polymer foams offer lightweight thermal/acoustic benefits. Asphalt-based products are less desirable due to odor, potential VOCs and long-term brittleness. Modern automotive sheets are often asphalt-free and designed with closed-cell layers to prevent corrosion and water absorption.

Standards and quality systems to check:

- IATF 16949 or ISO 9001 certification for consistent manufacturing quality.

- Compliance with RoHS and REACH for restricted substances.

- Flammability ratings such as UL94 or equivalent automotive flammability tests.

- Acoustic measurement standards for lab validation like ISO 10140 (laboratory measurement of sound insulation) or ASTM E90 where applicable.

Supply chain and manufacturing capacity considerations

Procurement must confirm supplier capacity, lead times, and contingency planning. Ask for typical lead times at different order volumes, minimum order quantities (MOQ), and the ability to scale production for program launches or peak seasons. Evaluate logistics: packaging that prevents deformation in transport, palletization standards, and preferred Incoterms for pricing clarity.

Key supply chain questions to ask suppliers:

- What is your standard lead time for serial production and for initial sample runs?

- What are your MOQs and ramp-up times for larger programs?

- Do you have multiple production lines or backup facilities to reduce risk?

- How do you package sheets to avoid stickiness or deformation in transit?

Quality assurance, testing, and traceability

Require a documented QA plan. This should include incoming material checks, in-process controls, final inspection criteria, and batch-level traceability. For NVH components, supplier test reports must include both raw material tests and finished product acoustic tests. Request third-party or accredited lab reports when possible.

Typical QA deliverables to request:

- Material certificates and raw material batch IDs.

- Finished product inspection reports (dimensions, weight, adhesion, visual).

- Acoustic performance test reports with clear test methodology.

- Environmental and aging tests: heat aging, cold flex, and humidity exposure.

- Sample retention policy for dispute resolution.

Commercial terms, pricing drivers and warranty

Price is driven by raw material costs (butyl polymers, metallic foils), sheet thickness, surface treatment, adhesive complexity and customization. When comparing quotes, normalize costs per square meter and consider the effective installed cost, not only sheet price. Include freight, duty, tooling, custom cutting and any installation aids.

Negotiate clear contractual terms:

- Unit price with volume tiers and effective date for material surcharges.

- Payment terms and acceptable payment methods.

- Warranty terms for adhesion and product integrity, including remedies.

- Acceptance criteria for returns and non-conforming goods.

Installation, packaging and after-sales support

Proper installation affects in-vehicle performance more than marginal differences in material data. Prefer suppliers who supply installation guides, standard cut patterns, pre-cut kits and training for technicians. Packaging should prevent self-adhesive surfaces from contaminating and should be clearly labeled with batch IDs and storage conditions.

Ask suppliers for:

- Installation manuals or short training videos.

- Recommended surface preparation and adhesives if additional bonding is required.

- Storage recommendations and shelf-life data.

- Spare parts or replacement policy and technical support contact.

Procurement evaluation checklist (matrix)

Use a simple scoring matrix to compare suppliers. Below is a ready-to-use checklist you can adapt.

| Evaluation Item | Required Evidence | Score (0-5) |

|---|---|---|

| Material Composition | Raw material list and MSDS | |

| Acoustic Test Data | ISO/ASTM lab reports | |

| Adhesion & Durability | Peel tests, heat aging reports | |

| Certifications | IATF/ISO, RoHS, REACH, UL | |

| Lead Time & Capacity | Production schedule, MOQ | |

| Commercial Terms | Price per m2, incoterm, warranty | |

| After-Sales Support | Training, installation aids, response SLAs |

How ASLONG Car Sound Damping Sheet meets procurement needs

When evaluating suppliers against the checklist above, ASLONG offers key advantages relevant to procurement teams:

- Purpose-designed Car Sound Damping Sheet with asphalt-free formulations for low odor and long-term stability.

- Clear technical documentation and test reports demonstrating mass per area, adhesion and acoustic performance.

- Production capacity with documented quality systems and traceability to support serial supply.

- Packaging and pre-cut options to simplify installation and reduce labor costs.

- Responsive after-sales support and guidance on installation best practices.

ASLONG's Car Sound Damping Sheet is designed for ease of installation and reliable NVH performance, making it a practical choice for both retrofit and OEM applications. For sample requests and bulk quotations, procurement teams should ask for technical data sheets, sample kits and a statement of conformity covering restricted substances.

Conclusion and next steps for procurement teams

Effective procurement of car sound damping material requires a balanced review of technical performance, manufacturing quality, supply chain reliability and commercial terms. Use the checklist and matrix above to standardize supplier comparisons. Request samples and independent test reports early in the selection cycle, and confirm installation support to protect acoustic performance in the vehicle.

Frequently Asked Questions (FAQ)

Q: What is the most important specification for a car sound damping sheet?

A: Adhesion and damping performance under expected temperature ranges are critical. Even a high-performing material will fail if it loses adhesion in service conditions.

Q: How do I compare prices between suppliers?

A: Normalize quotes to price per square meter and factor in installation labor, custom cutting, protective liners, and shipping. Consider total cost of ownership, not just unit price.

Q: Are all damping sheets safe for painted surfaces?

A: No. Some asphalt-based products can react with paints over long periods. Prefer asphalt-free formulations or verify compatibility via supplier-provided tests.

Q: What certifications should I insist on?

A: At minimum request ISO 9001 quality management or IATF 16949 for automotive programs, and compliance with RoHS/REACH. For fire safety, check UL or equivalent flammability reports.

Q: Can suppliers provide pre-cut kits for specific models?

A: Many experienced suppliers offer pre-cut patterns and adhesion-backed kits to reduce installation time and waste. Confirm tooling lead times and minimum order quantities for custom kits.

Contact and call to action

With suppliers shortlisted, engineers and buyers should align technical goals by understanding how car sound damping material cuts NVH and boosts vehicle quality.Ready to evaluate samples or request a quote? Contact our sales team to receive ASLONG Car Sound Damping Sheet samples, technical data sheets and pricing. For immediate support, request installation guides or an on-site training session to ensure correct application and best NVH results.

Authoritative references

- Soundproofing (Wikipedia): https://en.wikipedia.org/wiki/Soundproofing

- Butyl rubber (Wikipedia): https://en.wikipedia.org/wiki/Butyl_rubber

- IATF 16949 (Wikipedia): https://en.wikipedia.org/wiki/IATF_16949

- ISO 10140 (Sound insulation measurement overview): https://www.iso.org/standard/52916.

- RoHS Directive (EU): https://ec.europa.eu/environment/topics/waste-and-recycling/rohs_en

Use the procurement checklist above as your standard vendor evaluation tool to ensure the Car Sound Damping Sheet you buy delivers the NVH performance, durability and supply reliability required for your vehicles.

Best professional pvc foam for noise reduction manufacturers and supplier brands

How to start the electrical materials supply business ?

Wholesale acoustic panel material manufacturer and supplier

Design Considerations for Sound Absorbing White Cotton in Projects

FAQs

How to customize products that meet the needs of my industry?

You only need to contact our sales or technical team, we will conduct an in-depth analysis based on your industry needs and provide tailor-made products and solutions. We guarantee to provide you with efficient and accurate services to meet your personalized requirements.

Does ASLONG provide after-sales service?

Yes, we provide a full range of after-sales services, including technical support, installation guidance, product maintenance and quality tracking, etc., to ensure that each project goes smoothly and continues to perform at its best.

What specific functions can ASLONG's products provide?

Our products cover functions such as insulation, sound insulation, shock absorption, waterproofing and sealing, and are widely used in improving energy efficiency, reducing noise, controlling vibration, protecting equipment, etc., helping customers optimize engineering effects and improve user experience.

What industries are the products provided by ASLONG suitable for?

ASLONG's products are suitable for multiple industries, including air conditioning and HVAC, construction and waterproofing, automobiles and transportation, home appliances and electronics, industrial equipment and machinery, etc. We provide customized solutions for each industry to meet different needs.

Do ASLONG's products meet environmental protection standards?

Yes, all ASLONG products comply with ISO14001 environmental management system certification and global environmental protection standards. We use environmentally friendly materials and are committed to providing sustainable solutions to help customers achieve green development goals.

Butyl Rubber Sound Damping Mat

ASLONG Butyl Rubber Sound Damping Mat for sale. Effectively reduces noise and vibrations. High-quality butyl rubber ensures superior performance and durability. Ideal for automotive, industrial, and home applications.

Mass Loaded Vinyl

ASLONG Mass Loaded Vinyl for sale. Reduce noise pollution effectively with our high-quality, mass-loaded vinyl. Ideal for soundproofing walls, floors, and more. Buy now and experience the difference!

Egg Crate Foam

ASLONG Egg Crate Foam for sale. Lightweight, breathable, and comfortable, our egg crate foam provides superior support and pressure relief. Perfect for mattresses, cushions, cars, construction industry, KTV, factories, etc.

NBR Foam

ASLONG NBR Foam: Wholesale NBR foam solutions for diverse applications. High-quality, durable, and competitively priced. Contact us today for bulk orders.

Professional support at any time

If you have any comments or good suggestions, please leave us a message; later our professional staff will contact you as soon as possible.

© 2026 ASLONG All Rights Reserved. Privacy Policy | Terms and Conditions | Sitemap

Whatsapp: +8613242879341

ASLONG Global

ASLONG

Aslong_global