Key Specifications to Look for in Rubber Mats for Soundproofing

- Core material and mechanical specs that determine performance

- Material composition: why butyl matters

- Thickness and density: balancing mass and space

- Dynamic stiffness and loss factor (damping coefficient)

- Performance metrics, testing and standards to verify claims

- Key acoustic metrics: TL, STC, NRC and insertion loss

- Lab versus field testing: what to ask for

- Installation, durability, and safety specifications

- Adhesive backing, surface finish and ease of installation

- Environmental durability, temperature range and fire safety

- Comparisons, applications, and economic considerations

- Comparing rubber mats: Butyl vs neoprene, EPDM, foam

- Choosing by application: automotive, industrial and home use

- Cost vs. performance and lifecycle value

- Installation tips, maintenance and measurement

- Practical installation checklist

- Maintenance and longevity

- How to measure success post-installation

- References and standards

- Frequently Asked Questions (FAQ)

- How do I choose between a butyl rubber mat and an alternative material?

- What thickness and density should I use for automotive doors?

- Can rubber mats reduce both airborne and structure-borne noise?

- How should I verify manufacturer performance claims?

- Is the ASLONG Butyl Rubber Sound Damping Mat suitable for extreme temperatures?

Effective soundproofing depends on selecting rubber mats with the right combination of material properties, mechanical performance and installation features. This guide breaks down the specifications you should prioritize when choosing rubber mats for noise and vibration control, highlights how Butyl Rubber Sound Damping Mat compares to other options, and explains measurement standards and real-world installation tips that improve results for automotive, industrial, and home applications.

Core material and mechanical specs that determine performance

Material composition: why butyl matters

Material composition is the single most important specification for rubber mats used in soundproofing. Butyl rubber has a dense polymer matrix and intrinsic damping characteristics that convert vibrational energy into heat, reducing structure-borne noise. Compared with more elastic rubbers (like natural rubber) or closed-cell foams, butyl typically exhibits higher internal damping, greater mass per unit volume and superior long-term dimensional stability — all important for sustained noise reduction.

When evaluating compounds, look for manufacturer data on base polymer (butyl, EPDM, neoprene, nitrile), any fillers (e.g., mineral fillers for increased mass), and whether the product is a true damping mat (engineered to dissipate vibration) versus simple acoustic underlay. For authoritative background on sound control principles, see Wikipedia: Soundproofing.

Thickness and density: balancing mass and space

Thickness and density directly affect a mat’s mass-per-area, which is critical for reducing airborne transmission and improving low-frequency damping. Key points:

- Density (kg/m3 or g/cm3): Higher density increases mass and transmission loss, but also weight. Typical high-performance damping mats use dense butyl blends in the range of 1200–2000 kg/m3 depending on formulation and fillers.

- Thickness (mm): Thicker mats often improve low-frequency performance and isolation but may impact fit in tight spaces (e.g., automotive doors). Typical thicknesses for sound damping mats are 2–10 mm for vehicle panels and up to 10–20 mm for industrial floor or machinery mounts.

- Mass-per-area (kg/m2): A practical specification to compare products; higher mass-per-area usually yields better sound transmission loss at mid-to-low frequencies.

Choose thicker/higher-density mats where space allows and weight is acceptable; choose slimmer but higher-damping materials when clearance is limited.

Dynamic stiffness and loss factor (damping coefficient)

Beyond mass, dynamic stiffness (often in MN/m3) and loss factor (a dimensionless measure of energy dissipation) quantify how well a mat converts vibrational energy into heat. Lower dynamic stiffness improves vibration isolation; higher loss factor improves damping. Manufacturers should provide test data showing dynamic stiffness vs. frequency and loss factor. These metrics are particularly important for controlling structure-borne noise in vehicles, machinery mounts and building floors.

Performance metrics, testing and standards to verify claims

Key acoustic metrics: TL, STC, NRC and insertion loss

Understanding the right metrics helps translate product specs into expected real-world performance:

- Transmission Loss (TL): Laboratory measure of how much sound a material blocks across frequency bands. Important for comparing panels and assemblies.

- Sound Transmission Class (STC): A single-number rating derived from TL curves, useful for wall/floor assemblies in buildings.

- Noise Reduction Coefficient (NRC): Averaged absorption performance, more relevant for room acoustics than barrier mats.

- Insertion Loss: Field measure of how much noise is reduced at a target location after installing the mat.

For measurement protocols and definitions see the ISO standards library (e.g., ISO acoustic testing standards) and acoustics organizations such as the Acoustical Society of America.

Lab versus field testing: what to ask for

Lab test data is essential but does not always reflect performance when a mat is installed on complex assemblies. Ask suppliers for:

- Lab TL or STC test reports with clear test setup and frequency data.

- Field insertion loss measurements or case studies on similar applications (vehicle doors, machinery enclosures, floors).

- Data on how performance changes when mats are laminated, adhered, or combined with absorptive layers.

Reference testing protocols such as ISO and ASTM where possible to validate claims.

Installation, durability, and safety specifications

Adhesive backing, surface finish and ease of installation

Adhesion method determines installation speed, permanence, and performance. Common options include pressure-sensitive adhesive (peel-and-stick), self-adhesive with protective liner, or bare mats requiring separate adhesive or mechanical fastening. Consider:

- Adhesion strength (peel or shear values) and recommended primer or surface prep.

- Compatibility with paints, primers, or coatings used in your application.

- Conformability for curved surfaces in automotive door skins or machinery housings.

Good manufacturers provide clear installation instructions and recommended adhesives. Poor adhesion or improper installation can significantly reduce damping effectiveness and lead to failures over time.

Environmental durability, temperature range and fire safety

Sound damping mats may be exposed to heat, cold, oil/chemical splash, humidity and mechanical wear. Key specs to check:

- Operating temperature range: Look for mats rated for the extremes they will see in service (e.g., automotive engine bays may see >100°C intermittently).

- Chemical resistance: Resistance to oils, fuels, solvents or cleaning agents if used in industrial settings.

- UV and ozone resistance for exterior applications.

- Fire performance: UL 94 ratings or FMVSS/SAE testing for automotive fire spread and smoke/toxicity characteristics. Fire safety matters for building and industrial installations.

Regulatory and guidance documents on environmental health and noise include the WHO noise guidelines.

Comparisons, applications, and economic considerations

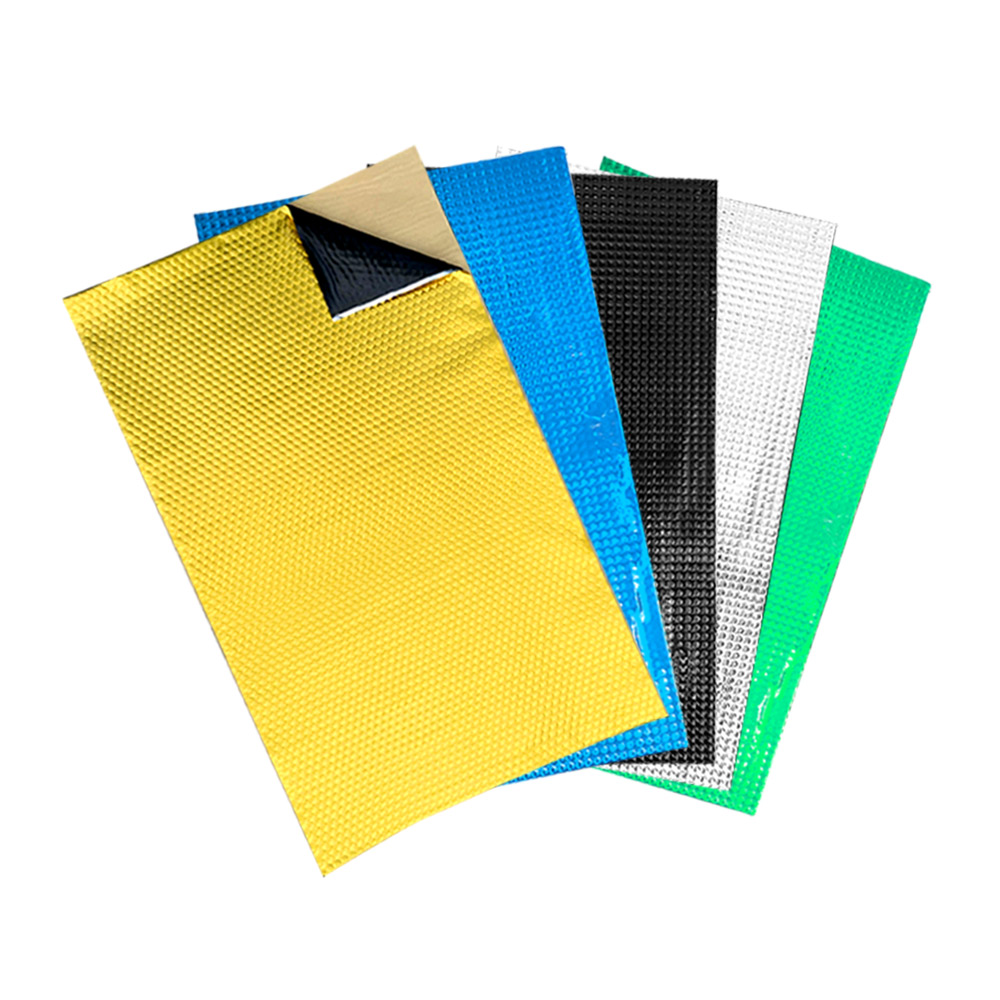

Comparing rubber mats: Butyl vs neoprene, EPDM, foam

The table below compares common materials to help you match product choice to application:

| Material | Typical Density | Thickness Range | Damping / TL | Best applications |

|---|---|---|---|---|

| Butyl Rubber (e.g., Butyl Rubber Sound Damping Mat) | ~1200–2000 kg/m3 (varies with fillers) | 2–10 mm (vehicle panels); thicker for floors | High damping; excellent low-frequency TL | Automotive doors, trunks, engine bays; machinery bases; floors |

| Neoprene | ~1000–1400 kg/m3 | 3–5 mm | Good general damping; better chemical resistance | Industrial mounts, general-purpose isolation |

| EPDM | ~900–1200 kg/m3 | 2–5 mm | Moderate damping; good weather/UV resistance | Exterior panels, HVAC ducting, outdoor enclosures |

| EVA / Closed-cell foam | ~100–500 kg/m3 | 3–20 mm | Low mass; good absorption at mid-high freq | Interior acoustic absorption, floor mats, packaging |

Choosing by application: automotive, industrial and home use

Match specifications to common scenarios:

- Automotive (doors, trunks, floors): Prioritize thin, high-damping butyl mats with adhesive backing and good temperature tolerance. Butyl Rubber Sound Damping Mat is engineered for these constraints—high performance at low thickness.

- Industrial (machinery base, enclosures): Prioritize dynamic stiffness, chemical resistance and heavy-duty adhesion or mechanical fastening. Thicker mats and composite systems (damping + isolation) often work best.

- Home (apartment walls, floors, HVAC): For airborne noise consider mass-loaded products or a composite strategy (mass + resilient channel + absorption). For floors, impact isolation may require specific resilient underlays in addition to damping mats.

Cost vs. performance and lifecycle value

High-density butyl mats often cost more upfront but deliver superior damping, durability and lower maintenance over time. Consider total lifecycle value:

- Installation labor and time

- Weight implications (for vehicles)

- Replacement frequency

- Energy or productivity gains from reduced noise

Product spotlight:

ASLONG Butyl Rubber Sound Damping Mat for sale. Effectively reduces noise and vibrations. High-quality butyl rubber ensures superior performance and durability. Ideal for automotive, industrial, and home applications.

Installation tips, maintenance and measurement

Practical installation checklist

Follow these steps to maximize mat performance:

- Clean and degrease the surface; remove rust, loose paint and contaminants.

- Ensure correct temperature range for adhesive application (manufacturer’s guidance).

- Use rollers to eliminate trapped air and ensure full contact.

- Seal edges where moisture ingress is a concern.

- Combine with absorptive layers where airborne absorption is needed (e.g., foam behind panels).

Maintenance and longevity

Butyl damping mats are low-maintenance. Periodic inspections for lifting edges or chemical attack are recommended in harsh environments. If mats are exposed to oils or solvents, choose a formulation with proven chemical resistance.

How to measure success post-installation

Conduct simple field tests to evaluate efficacy:

- Use a calibrated sound level meter to measure insertion loss at relevant frequencies before and after installation.

- For vehicle applications, test door slams, road noise at set speeds, and operational noise sources (engine, HVAC).

- Document results and compare to lab TL/STC numbers to understand real-world differences.

References and standards

For further reading and standard definitions consult:

- Wikipedia: Soundproofing — overview of methods and concepts.

- ISO acoustic measurement standards — reference for TL/STC and laboratory testing procedures.

- Acoustical Society of America — professional society with resources and research on noise control.

- WHO: Environmental noise — health impact guidance and policy references.

Frequently Asked Questions (FAQ)

How do I choose between a butyl rubber mat and an alternative material?

Choose butyl when you need high damping, good low-frequency performance, and long-term dimensional stability (e.g., automotive panels, machinery enclosures). Choose neoprene or EPDM if you need better chemical or weather resistance; choose closed-cell foam when weight and high-frequency absorption are the primary concerns.

What thickness and density should I use for automotive doors?

For door skins and cavities, 2–5 mm butyl mats with high loss factor and good adhesive backing are typical. Thicker materials add weight and can be impractical in tight assemblies. Measure the available cavity space and consult the mat’s mass-per-area to estimate expected transmission loss.

Can rubber mats reduce both airborne and structure-borne noise?

Rubber damping mats are most effective at reducing structure-borne noise and low-frequency vibration. For airborne noise you may need to combine mass (barrier) with absorption layers and proper assembly sealing. A composite approach (damping + mass + absorption) often yields the best overall reduction.

How should I verify manufacturer performance claims?

Request lab TL/STC reports and field insertion loss data. Verify tests reference recognized standards (ISO/ASTM) and review the test conditions. If possible, pilot a small installation and measure before/after sound levels with a calibrated meter.

Is the ASLONG Butyl Rubber Sound Damping Mat suitable for extreme temperatures?

ASLONG’s butyl formulations are engineered for a broad operating range suitable for many automotive and industrial environments. For extreme conditions (very high engine bay temperatures or sub-zero climates), request the specific product datasheet for exact operating temperature limits and chemical resistance details.

If you’d like product specifications, datasheets, or a custom recommendation for your application, contact our technical team or view the product page:

How to manufacturing acoustic ceiling material

Mass Loaded Vinyl and Sound Transmission Class Explained

Tips for buy sound deadening for cars

Top sound insulation materials Manufacturers and Suppliers

FAQs

What industries are the products provided by ASLONG suitable for?

ASLONG's products are suitable for multiple industries, including air conditioning and HVAC, construction and waterproofing, automobiles and transportation, home appliances and electronics, industrial equipment and machinery, etc. We provide customized solutions for each industry to meet different needs.

What specific functions can ASLONG's products provide?

Our products cover functions such as insulation, sound insulation, shock absorption, waterproofing and sealing, and are widely used in improving energy efficiency, reducing noise, controlling vibration, protecting equipment, etc., helping customers optimize engineering effects and improve user experience.

How to customize products that meet the needs of my industry?

You only need to contact our sales or technical team, we will conduct an in-depth analysis based on your industry needs and provide tailor-made products and solutions. We guarantee to provide you with efficient and accurate services to meet your personalized requirements.

Do ASLONG's products meet environmental protection standards?

Yes, all ASLONG products comply with ISO14001 environmental management system certification and global environmental protection standards. We use environmentally friendly materials and are committed to providing sustainable solutions to help customers achieve green development goals.

Does ASLONG provide after-sales service?

Yes, we provide a full range of after-sales services, including technical support, installation guidance, product maintenance and quality tracking, etc., to ensure that each project goes smoothly and continues to perform at its best.

Butyl Rubber Sound Damping Mat

ASLONG Butyl Rubber Sound Damping Mat for sale. Effectively reduces noise and vibrations. High-quality butyl rubber ensures superior performance and durability. Ideal for automotive, industrial, and home applications.

Mass Loaded Vinyl

ASLONG Mass Loaded Vinyl for sale. Reduce noise pollution effectively with our high-quality, mass-loaded vinyl. Ideal for soundproofing walls, floors, and more. Buy now and experience the difference!

Egg Crate Foam

ASLONG Egg Crate Foam for sale. Lightweight, breathable, and comfortable, our egg crate foam provides superior support and pressure relief. Perfect for mattresses, cushions, cars, construction industry, KTV, factories, etc.

NBR Foam

ASLONG NBR Foam: Wholesale NBR foam solutions for diverse applications. High-quality, durable, and competitively priced. Contact us today for bulk orders.

Professional support at any time

If you have any comments or good suggestions, please leave us a message; later our professional staff will contact you as soon as possible.

© 2026 ASLONG All Rights Reserved. Privacy Policy | Terms and Conditions | Sitemap

Whatsapp: +8613242879341

ASLONG Global

ASLONG

Aslong_global