Key Metrics for Car Sound Damping Sheets: Weight & Durability

- Key Metrics for Car Sound Damping Sheets: Weight & Durability

- Why weight and durability matter for car sound damping material

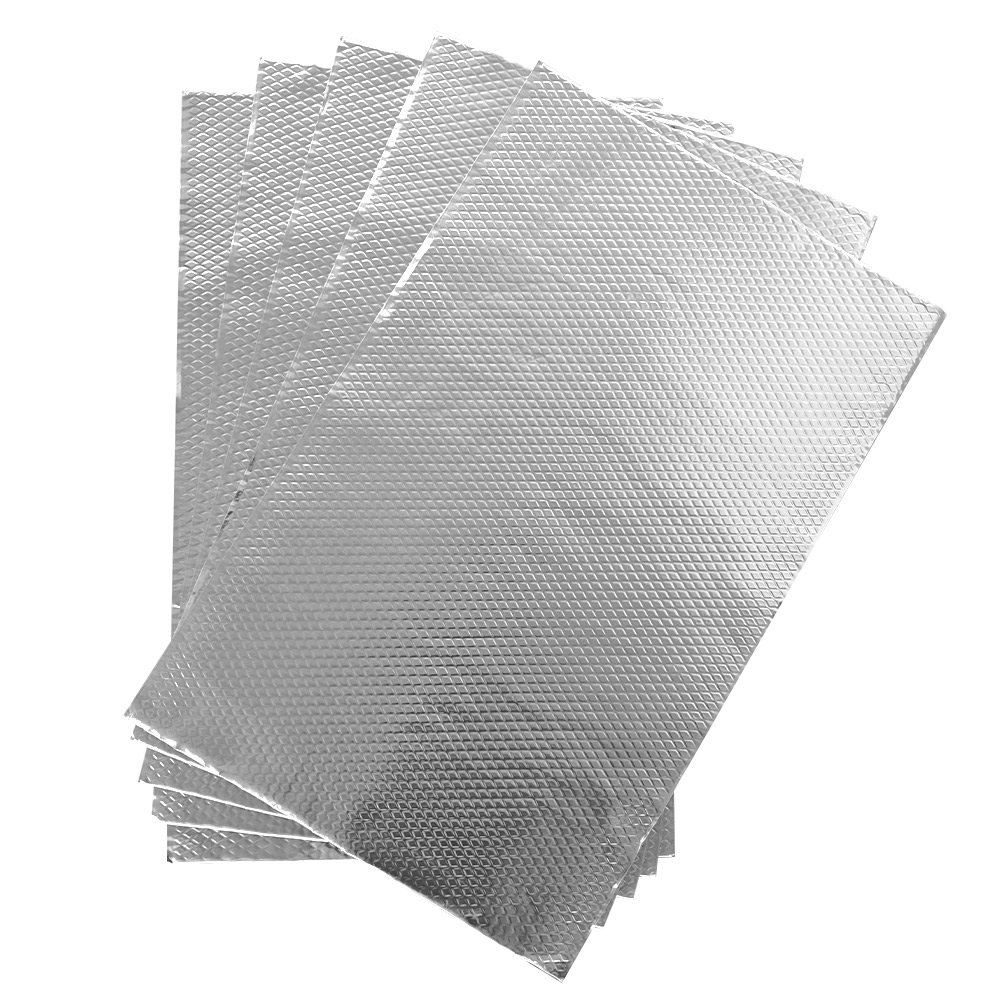

- Product introduction: ASLONG Car Sound Damping Sheet

- Understanding weight: mass-per-area and its role in sound damping

- How mass interacts with frequency

- Key weight metrics to check before purchase

- Durability: what it means for car sound damping sheets

- Practical durability indicators to evaluate

- Testing standards and lab methods for weight and durability

- How to read test results

- Balancing weight vs. durability: trade-offs and selection guidance

- Recommended approach

- Comparison table: typical metrics for damping sheet types

- Installation and maintenance: how these affect durability

- Common installation mistakes that shorten life

- Selecting the right car sound damping material for different vehicle needs

- Why ASLONG Car Sound Damping Sheet works for many applications

- Brand advantages: ASLONG product strengths summarized

- FAQs — Car Sound Damping Material & Car Sound Damping Sheet

- Q: How much weight will a damping sheet add to my car?

- Q: Will adding damping sheets improve fuel economy?

- Q: How long will a good car sound damping material last?

- Q: Can I install damping sheets myself?

- Q: How do I verify a product's claims?

- Contact & product CTA

- Authoritative references and further reading

Key Metrics for Car Sound Damping Sheets: Weight & Durability

Why weight and durability matter for car sound damping material

When selecting a car sound damping material, two metrics consistently determine real-world performance: weight (often expressed as mass per unit area) and durability (how long the material maintains its damping properties under vehicle conditions). A correctly weighted damping sheet converts and dissipates vibrational energy more effectively, while durable materials retain adhesion and mechanical integrity despite temperature swings, moisture, and mechanical stress. For drivers, that means lower road noise, fewer rattles, and lasting comfort without frequent replacement. Beyond performance, modern OEM programs increasingly require adherence to sustainability criteria when sourcing car sound damping materials.

Product introduction: ASLONG Car Sound Damping Sheet

Discover the ASLONG Car Sound Damping Sheet—High Quality sound damping material designed to reduce road noise and vibration. Improve your driving comfort with this easy-to-install, durable car sound damping sheet for superior sound insulation.

Understanding weight: mass-per-area and its role in sound damping

In automotive noise control, weight is most usefully described as mass per unit area (g/m² or kg/m²). The higher the mass per area, the more the material resists vibration and the greater its low-frequency damping potential. However, vehicle designers and retrofitters must balance damping mass against added weight to the vehicle (fuel economy, handling) and installation constraints. A proper car sound damping material will optimize mass distribution—placing heavier sheets where panels are thin and prone to vibrate (doors, floor pans, trunk lids), and lighter treatments where additional mass would be inefficient.

How mass interacts with frequency

Mass loading reduces transmission of low-frequency vibrations, because heavier barriers require more energy to accelerate. High-frequency noise is often better addressed by viscoelastic damping layers that convert vibrational energy into heat. Therefore, the ideal car sound damping sheet combines sufficient mass (to address low-frequency sources) and viscoelastic composition (to handle mid-to-high frequency vibrations). Choosing a car sound damping material without considering the mass-frequency relationship leads to underperformance in the frequencies most audible inside the cabin.

Key weight metrics to check before purchase

Look for the following specifications on product datasheets for any car sound damping material:

- Mass per unit area (g/m² or kg/m²)

- Thickness (mm) — often correlates with mass and stiffness

- Density (kg/m³) — useful when cross-comparing materials

- Effective frequency range — indicated or measured in lab tests

These metrics let you predict installation coverage, expected acoustic benefit, and the trade-offs in weight added to the vehicle.

Durability: what it means for car sound damping sheets

Durability covers a group of performance attributes: adhesive longevity, resistance to temperature cycling, moisture resistance, UV and chemical stability, mechanical fatigue, and retention of viscoelastic damping properties over time. In automotive environments, damping sheets face extremes: hot summer temperatures in engine bays or trunk areas, cold winter starts, road salt and moisture, and repeated flexing of panels. Long-term value is delivered by products that maintain adhesion and damping efficiency across these conditions.

Practical durability indicators to evaluate

When reviewing a car sound damping material's claims, prioritize the following test-based or specification indicators:

- Adhesion strength (N/cm or peel strength) — higher values indicate better long-term stickiness

- Temperature operating range (°C) — indicates resistance to softening or embrittlement

- Water/steam resistance and corrosion inhibition if the sheet has anti-rust layers

- Fatigue/endurance testing results (cycles to failure) where available

Testing standards and lab methods for weight and durability

Several lab methods and industry standards guide objective measurement of the metrics above. Common references include acoustic transmission and impedance tube tests for frequency response, peel and shear adhesion tests for bonding durability, and environmental aging tests that simulate thermal cycling and humidity. While some standards are industry-specific, look for publicly available test reports or third-party test certifications to confirm manufacturer claims about a car sound damping material.

How to read test results

Ask for test results that show before-and-after cabin sound pressure levels (SPL) or objective transmission loss (TL) numbers for panels treated with a damping sheet. Also request adhesion test reports and environmental aging summaries. Third-party testing (independent labs or recognized bodies) provides the strongest evidence of durability and performance.

Balancing weight vs. durability: trade-offs and selection guidance

Higher-mass materials generally increase damping but also add weight and can be less flexible to install. Very lightweight damping sheets may be easy to apply but fail to meaningfully reduce low-frequency noise. Durability adds another axis: a heavy material that delaminates after a year is worse than a slightly lighter material that performs for a decade. Choose a car sound damping material based on your priorities: maximum noise reduction, minimal added weight, ease of DIY installation, or long-term service life.

Recommended approach

1) Map the vehicle's highest-vibration panels (door skins, floor sections, trunk lid) and allocate heavier, higher-mass sheets there. 2) Use thinner, high-viscoelastic sheets for small panels and where weight is critical. 3) Prioritize materials with proven adhesion and temperature resistance in zones exposed to heat or moisture. This targeted approach yields better cabin quieting with less total added mass.

Comparison table: typical metrics for damping sheet types

The table below summarizes typical ranges you will see when comparing common car sound damping sheets and the ASLONG Car Sound Damping Sheet (example specification). Actual product datasheets should be consulted for precise values.

| Type | Mass per area (g/m²) | Thickness (mm) | Adhesion (peel, N/cm) | Typical service life (years) | Notes |

|---|---|---|---|---|---|

| Lightweight viscoelastic sheet | 800–1,800 | 1.0–1.8 | 3–6 | 3–7 | Good for mid/high frequencies, easy to apply |

| Medium mass damping sheet | 1,800–3,000 | 1.8–3.0 | 5–8 | 5–10 | Balanced performance across frequency range |

| High mass/rubberized sheet | 3,000–5,000+ | 3.0–5.0+ | 6–10 | 6–12 | Excellent low-frequency reduction but heavier |

| ASLONG Car Sound Damping Sheet (example) | ~3,200 | ~3.2 | >6 | 8–12 | Designed for balance of low-frequency damping and durability |

Installation and maintenance: how these affect durability

Correct installation greatly extends the effective life of any car sound damping material. Surface preparation is critical: clean, degrease and dry metal or plastic surfaces before applying the sheet. Use recommended rollers to ensure full contact and avoid trapped air pockets. Overlap or butt joints should follow manufacturer guidance to prevent ingress of moisture. Maintenance is typically minimal, but inspect treated areas when you service panels or trim; if adhesion has failed, reapply with compatible adhesive or replace the sheet in that zone.

Common installation mistakes that shorten life

Applying damping sheets on dirty or oily surfaces, using heat guns beyond recommended temperatures (which can degrade adhesive), and installing in cold conditions without pre-warming the sheet can all lead to early delamination and loss of damping performance.

Selecting the right car sound damping material for different vehicle needs

Consider the following selection guidance:

- Daily commuter: Choose balanced mass (1,800–3,000 g/m²) with strong adhesion and a service life claim of 5+ years.

- High-performance or luxury upgrades: Use higher mass in strategic locations for superior low-frequency reduction, and lightweight viscoelastic layers for response-sensitive areas.

- Off-road or harsh climates: Prioritize temperature range, moisture resistance, and corrosion-inhibiting backings.

- DIY installers: Look for pre-cut kits, peel-and-stick backing, and clear installation guides.

Why ASLONG Car Sound Damping Sheet works for many applications

The ASLONG Car Sound Damping Sheet is engineered as a balanced solution: sufficient mass for low-frequency control, viscoelastic composition for mid-high frequency damping, and a durable adhesive designed to withstand temperature and moisture changes. For many users, this combination reduces interior noise while maintaining an easy installation process and long service life.

Brand advantages: ASLONG product strengths summarized

ASLONG focuses on reliable, application-driven sound control for vehicles. Key advantages include:

- Balanced mass and viscoelastic formulation to address a broad frequency range.

- Strong adhesive with good peel strength for long-term bonding.

- Temperature and moisture resistance designed for automotive environments.

- Clear installation guidance to help installers achieve optimal contact and coverage.

FAQs — Car Sound Damping Material & Car Sound Damping Sheet

Q: How much weight will a damping sheet add to my car?

A: It depends on coverage and product mass per area. Typical treatments add 1–10 kg depending on how much of the vehicle you treat. Targeted treatments (doors and trunk) can yield major noise reduction with modest total added weight.

Q: Will adding damping sheets improve fuel economy?

A: Adding mass generally increases vehicle weight slightly and may have a negligible negative effect on fuel economy. However, the comfort and NVH benefits often outweigh small efficiency losses. Strategic, targeted application minimizes added weight while maximizing acoustic gains.

Q: How long will a good car sound damping material last?

A: With proper installation and in typical vehicle environments, high-quality damping sheets often last 8–12 years. Service life depends on adhesive chemistry, exposure to extreme temperatures, and whether panels are disturbed.

Q: Can I install damping sheets myself?

A: Yes. Many car sound damping materials, including the ASLONG Car Sound Damping Sheet, are designed for peel-and-stick installation. Proper surface prep, heating in cold conditions, and using a roller for full contact will improve results.

Q: How do I verify a product's claims?

A: Request or review third-party test results, product datasheets showing mass per area, adhesion figures and temperature ranges, and independent user reviews or installation case studies.

Contact & product CTA

If you want to reduce road noise and improve cabin comfort, check the ASLONG Car Sound Damping Sheet for a balanced solution of weight, durability and ease of installation. Contact our sales team for datasheets, sample packs and application guidance, or view the product page to select the kit that fits your vehicle.

Contact us: For technical questions and to request test reports or sample kits, please contact our support team or visit the ASLONG product page.

Authoritative references and further reading

For technical background and standards related to noise control, damping materials and automotive NVH, consider these authoritative sources:

- Noise control and acoustic basics — Wikipedia: https://en.wikipedia.org/wiki/Noise_control

- Soundproofing overview — Wikipedia: https://en.wikipedia.org/wiki/Soundproofing

- Acoustical Society of America (technical resources): https://acousticalsociety.org/

- U.S. Environmental Protection Agency — Noise: https://www.epa.gov/transportation-air-pollution-and-climate-change/noise

- Basics of vehicle NVH — Technical literature and SAE overviews: https://www.sae.org/ (search for vehicle NVH resources)

Note: Product specifications in this article are representative. Always consult ASLONG product datasheets and installation guides for exact numbers and recommended practices.

Top 10 car soundproofing material Manufacturers and Supplier Brands

Top 5 sound insulation materials Company List and Products Compared

Best professional wall sound insulation materials manufacturers and supplier brands

Eco-Friendly Automotive Sound Insulation Materials 2026

FAQs

How to customize products that meet the needs of my industry?

You only need to contact our sales or technical team, we will conduct an in-depth analysis based on your industry needs and provide tailor-made products and solutions. We guarantee to provide you with efficient and accurate services to meet your personalized requirements.

Does ASLONG provide after-sales service?

Yes, we provide a full range of after-sales services, including technical support, installation guidance, product maintenance and quality tracking, etc., to ensure that each project goes smoothly and continues to perform at its best.

What industries are the products provided by ASLONG suitable for?

ASLONG's products are suitable for multiple industries, including air conditioning and HVAC, construction and waterproofing, automobiles and transportation, home appliances and electronics, industrial equipment and machinery, etc. We provide customized solutions for each industry to meet different needs.

What specific functions can ASLONG's products provide?

Our products cover functions such as insulation, sound insulation, shock absorption, waterproofing and sealing, and are widely used in improving energy efficiency, reducing noise, controlling vibration, protecting equipment, etc., helping customers optimize engineering effects and improve user experience.

Do ASLONG's products meet environmental protection standards?

Yes, all ASLONG products comply with ISO14001 environmental management system certification and global environmental protection standards. We use environmentally friendly materials and are committed to providing sustainable solutions to help customers achieve green development goals.

Butyl Rubber Sound Damping Mat

ASLONG Butyl Rubber Sound Damping Mat for sale. Effectively reduces noise and vibrations. High-quality butyl rubber ensures superior performance and durability. Ideal for automotive, industrial, and home applications.

Mass Loaded Vinyl

ASLONG Mass Loaded Vinyl for sale. Reduce noise pollution effectively with our high-quality, mass-loaded vinyl. Ideal for soundproofing walls, floors, and more. Buy now and experience the difference!

Egg Crate Foam

ASLONG Egg Crate Foam for sale. Lightweight, breathable, and comfortable, our egg crate foam provides superior support and pressure relief. Perfect for mattresses, cushions, cars, construction industry, KTV, factories, etc.

NBR Foam

ASLONG NBR Foam: Wholesale NBR foam solutions for diverse applications. High-quality, durable, and competitively priced. Contact us today for bulk orders.

Professional support at any time

If you have any comments or good suggestions, please leave us a message; later our professional staff will contact you as soon as possible.

© 2026 ASLONG All Rights Reserved. Privacy Policy | Terms and Conditions | Sitemap

Whatsapp: +8613242879341

ASLONG Global

ASLONG

Aslong_global