Vibration Isolation: Rubber Mats Solutions for Machinery Noise

- Understanding Vibration Sources and Transmission Paths

- Types of vibration and how they generate noise

- Transmission paths and diagnosis

- Why isolating the path matters more than blocking air

- Why Butyl Rubber Sound Damping Mats Excel

- Material properties that matter

- Product highlight

- Evidence and standards supporting damping performance

- Selecting the Right Rubber Mats for Your Application

- Key selection criteria

- Comparing common rubber mat materials

- How to read dynamic stiffness and transmissibility charts

- Practical Installation and Maintenance for Machinery

- Surface preparation and mounting best practices

- Layering and combining materials for optimal results

- Maintenance, durability, and lifecycle considerations

- Measuring Performance and ROI

- How to quantify noise and vibration reduction

- Cost-benefit: when mats make financial sense

- Case example: machinery floor mounting

- FAQ — Common Questions About Rubber Mats and Vibration Isolation

- Q: Are rubber mats effective for all types of machinery?

- Q: How thick should a butyl rubber damping mat be?

- Q: Can I use adhesive-backed butyl mats in oily or high-temperature environments?

- Q: How long do butyl rubber mats last?

- Q: Will adding mats create a fire hazard?

Vibration isolation and sound damping using rubber mats provide a cost-effective, durable solution for controlling machinery noise across automotive, industrial, and residential settings. Properly selected and installed rubber mats can reduce structure-borne noise, improve machine longevity, and create safer, more comfortable environments while meeting regulatory noise limits. This guide explains how rubber mats work, why butyl rubber is often preferred, how to choose and install damping mats, and answers common buyer questions.

Understanding Vibration Sources and Transmission Paths

Types of vibration and how they generate noise

Machinery vibration arises from imbalance, misalignment, gear meshing, impacts, and resonance. These vibrations couple into structures and radiate as airborne noise. Distinguishing between airborne and structure-borne noise is critical: airborne noise travels through air, while structure-borne noise transmits through machine frames and building structures, often amplified by panels, floors, and enclosures.

Transmission paths and diagnosis

Identify transmission paths—mounts, bolts, baseplates, and contact surfaces—before specifying a solution. Simple diagnostic methods include: listening for tonal vs broadband noise, using a rubber mallet to excite structures and observe resonant response, and handheld accelerometers to map vibration levels. For in-depth measurement and standards, see ISO guidance on sound insulation and measurement (ISO 10140).

Why isolating the path matters more than blocking air

Airborne noise control (panels, barriers) is important, but structure-borne vibration often causes low-frequency noise that is hardest to mitigate by barriers alone. Vibration isolation—decoupling the source from the structure—addresses the root cause and is especially effective when combined with damping layers like rubber mats.

Why Butyl Rubber Sound Damping Mats Excel

Material properties that matter

Butyl rubber combines high damping capacity, low gas permeability, and long-term dimensional stability. These properties translate to consistent vibration energy absorption and sound damping across a wide range of frequencies. Compared to harder elastomers, butyl typically offers superior energy dissipation (loss factor) in the sub-500 Hz region where machine noise is most perceptible.

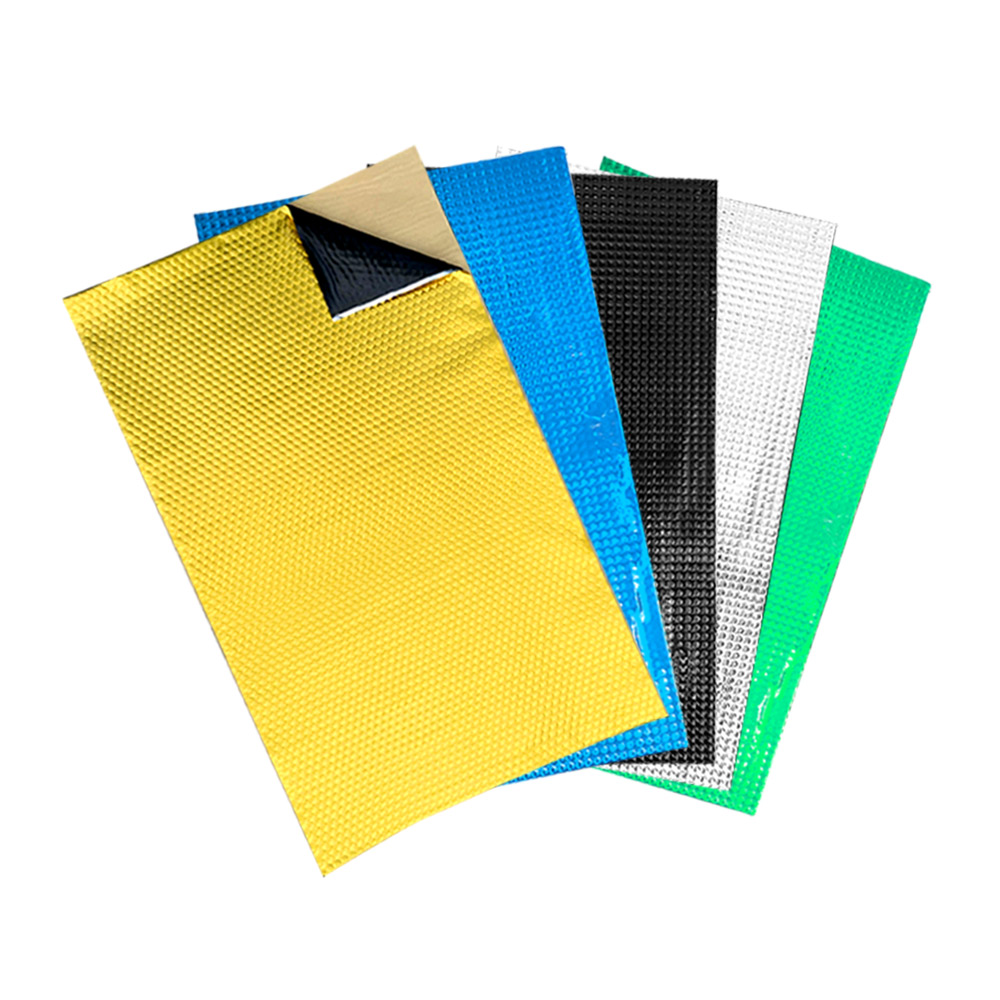

Product highlight

ASLONG Butyl Rubber Sound Damping Mat for sale. Effectively reduces noise and vibrations. High-quality butyl rubber ensures superior performance and durability. Ideal for automotive, industrial, and home applications.

Evidence and standards supporting damping performance

Designers often refer to acoustical research and standards to quantify performance. The Acoustical Society of America provides guidance on vibration control and damping strategies (Acoustical Society of America). For public-health-exposure context, see WHO Environmental Noise Guidelines (WHO 2018), which emphasize reducing noise impacts on health.

Selecting the Right Rubber Mats for Your Application

Key selection criteria

Consider load capacity, dynamic stiffness, damping factor, temperature range, chemical exposure, and installation footprint. For rotating machinery with concentrated loads, choose mats with higher compressive strength. For large panels or platforms, prioritize dynamic stiffness and shear damping to prevent resonance transmission.

Comparing common rubber mat materials

Below is a concise comparison of typical rubber mat types used for vibration isolation and sound damping:

| Material | Typical Damping | Temp Range | Durability / Notes |

|---|---|---|---|

| Butyl Rubber (e.g., Butyl Sound Damping Mat) | High (excellent low-freq damping) | -30°C to +100°C | Low permeability, long-term stable, ideal for NVH control |

| Neoprene | Moderate | -40°C to +120°C | Good weather and oil resistance |

| EPDM | Moderate | -50°C to +150°C | Excellent UV/ozone resistance, outdoor use |

| EVA / Foam Mats | Lower (better for impact isolation) | -20°C to +80°C | Lightweight, economical, less durable under heavy loads |

How to read dynamic stiffness and transmissibility charts

Dynamic stiffness (N/mm) and transmissibility graphs help predict isolation at operating frequencies. Aim for a system natural frequency at least 1/3 of the excitation frequency for effective isolation (rule-of-thumb). Manufacturers often provide transmissibility curves—use these to size mat thickness and area per load point.

Practical Installation and Maintenance for Machinery

Surface preparation and mounting best practices

Ensure contact surfaces are clean, flat, and free of lubricants. For adhesive-backed damping mats, clean with isopropyl alcohol and allow to dry. When using mats under feet or baseplates, arrange mats so load is evenly distributed; use shims or plates if necessary to prevent edge loading. For high-precision equipment, pair mats with spring mounts for combined isolation across broad frequency bands.

Layering and combining materials for optimal results

Often the best results come from layering: a soft damping mat (butyl) for energy absorption, plus a firmer isolator (rubber pad or spring) for static support. Sandwich constructions can target both low-frequency vibration and high-frequency airborne noise. Avoid overly thin mats under heavy loads—these can bottom out and lose effectiveness.

Maintenance, durability, and lifecycle considerations

Inspect mats periodically for compression set, tears, or chemical degradation. Butyl rubber typically maintains performance longer than many elastomers; however, excessive heat, oils, or solvents can accelerate aging. Replace mats when static deflection increases significantly or when measured vibration reduction degrades beyond acceptable limits.

Measuring Performance and ROI

How to quantify noise and vibration reduction

Use a combination of sound level meters (for dB(A) reductions) and accelerometers (for structure-borne vibration in g or mm/s). Pre- and post-installation measurements at the same locations and operational conditions give reliable results. ISO and industry test methods help standardize measurements (see ISO 10140). For practical limits, a 3 dB reduction is the minimum perceptible change; 6–10 dB is considered clearly noticeable and meaningful to users.

Cost-benefit: when mats make financial sense

Factors include downtime reduction, reduced maintenance from vibration-related fatigue, improved worker comfort and compliance with noise limits, and potential product claims (e.g., quieter equipment). A simple ROI model compares material and installation cost against avoided costs (repair, lost production, regulatory fines, or customer complaints).

Case example: machinery floor mounting

Installing high-performance butyl damping mats under a printing press or HVAC compressor can reduce radiated low-frequency noise by several dB and significantly lower transmitted vibrations into building structures. Measured results are application-specific but often justify the investment in industrial settings.

FAQ — Common Questions About Rubber Mats and Vibration Isolation

Q: Are rubber mats effective for all types of machinery?

A: Rubber mats are highly effective for many machines, especially where structure-borne vibration is the dominant path. For extremely low-frequency or very heavy equipment, combine mats with spring isolators or specialized mounts. For airborne high-frequency noise, consider complementary absorptive materials or enclosures.

Q: How thick should a butyl rubber damping mat be?

A: Thickness depends on load and target frequency range. Typical thicknesses range from 3 mm for light damping to 10–20 mm (or more) for heavy-duty vibration isolation. Use manufacturer transmissibility data and area-per-load calculations for precise specification.

Q: Can I use adhesive-backed butyl mats in oily or high-temperature environments?

A: Butyl rubber is chemically resistant, but adhesive performance may degrade with oils or heat. For harsh environments, choose mechanical fixing or specialized high-temperature adhesives and verify chemical compatibility with supplier data sheets.

Q: How long do butyl rubber mats last?

A: With normal indoor use, butyl mats can last many years with minimal performance loss. Lifespan shortens under UV exposure, extreme heat, or aggressive chemicals. Regular inspection and proper installation prolong service life.

Q: Will adding mats create a fire hazard?

A: Most industrial-grade rubber mats are formulated to meet flammability standards; always check fire-rating specifications for your application and maintain clearance from open flames and hot surfaces.

If you have specific equipment, load data, or frequency information, contact our technical team for a tailored recommendation and calculation. View the product page or get a quote: ASLONG Butyl Rubber Sound Damping Mat.

References and further reading: Soundproofing — Wikipedia; WHO Environmental Noise Guidelines; ISO 10140 — Acoustic testing; Acoustical Society of America.

Contact us for samples, technical datasheets, and installation guides — or visit our product page to buy now: Contact Sales | View Product.

Fire, Health and Environmental Safety of Mass Loaded Vinyl

Butyl Rubber Sound Damping Mat: Technical Specs Buyers Need

Wholesale soundproofing material manufacturer and supplier

The B2B Buyer’s Guide to egg crate foam roll | ASLONG Ultimate Insights

FAQs

What industries are the products provided by ASLONG suitable for?

ASLONG's products are suitable for multiple industries, including air conditioning and HVAC, construction and waterproofing, automobiles and transportation, home appliances and electronics, industrial equipment and machinery, etc. We provide customized solutions for each industry to meet different needs.

How to customize products that meet the needs of my industry?

You only need to contact our sales or technical team, we will conduct an in-depth analysis based on your industry needs and provide tailor-made products and solutions. We guarantee to provide you with efficient and accurate services to meet your personalized requirements.

What specific functions can ASLONG's products provide?

Our products cover functions such as insulation, sound insulation, shock absorption, waterproofing and sealing, and are widely used in improving energy efficiency, reducing noise, controlling vibration, protecting equipment, etc., helping customers optimize engineering effects and improve user experience.

Do ASLONG's products meet environmental protection standards?

Yes, all ASLONG products comply with ISO14001 environmental management system certification and global environmental protection standards. We use environmentally friendly materials and are committed to providing sustainable solutions to help customers achieve green development goals.

Does ASLONG provide after-sales service?

Yes, we provide a full range of after-sales services, including technical support, installation guidance, product maintenance and quality tracking, etc., to ensure that each project goes smoothly and continues to perform at its best.

Butyl Rubber Sound Damping Mat

ASLONG Butyl Rubber Sound Damping Mat for sale. Effectively reduces noise and vibrations. High-quality butyl rubber ensures superior performance and durability. Ideal for automotive, industrial, and home applications.

Mass Loaded Vinyl

ASLONG Mass Loaded Vinyl for sale. Reduce noise pollution effectively with our high-quality, mass-loaded vinyl. Ideal for soundproofing walls, floors, and more. Buy now and experience the difference!

Egg Crate Foam

ASLONG Egg Crate Foam for sale. Lightweight, breathable, and comfortable, our egg crate foam provides superior support and pressure relief. Perfect for mattresses, cushions, cars, construction industry, KTV, factories, etc.

NBR Foam

ASLONG NBR Foam: Wholesale NBR foam solutions for diverse applications. High-quality, durable, and competitively priced. Contact us today for bulk orders.

Professional support at any time

If you have any comments or good suggestions, please leave us a message; later our professional staff will contact you as soon as possible.

© 2026 ASLONG All Rights Reserved. Privacy Policy | Terms and Conditions | Sitemap

Whatsapp: +8613242879341

ASLONG Global

ASLONG

Aslong_global