Butyl Rubber Sound Damping Mat: Technical Specs Buyers Need

- Butyl Rubber Sound Damping Mat: Technical Specs Buyers Need

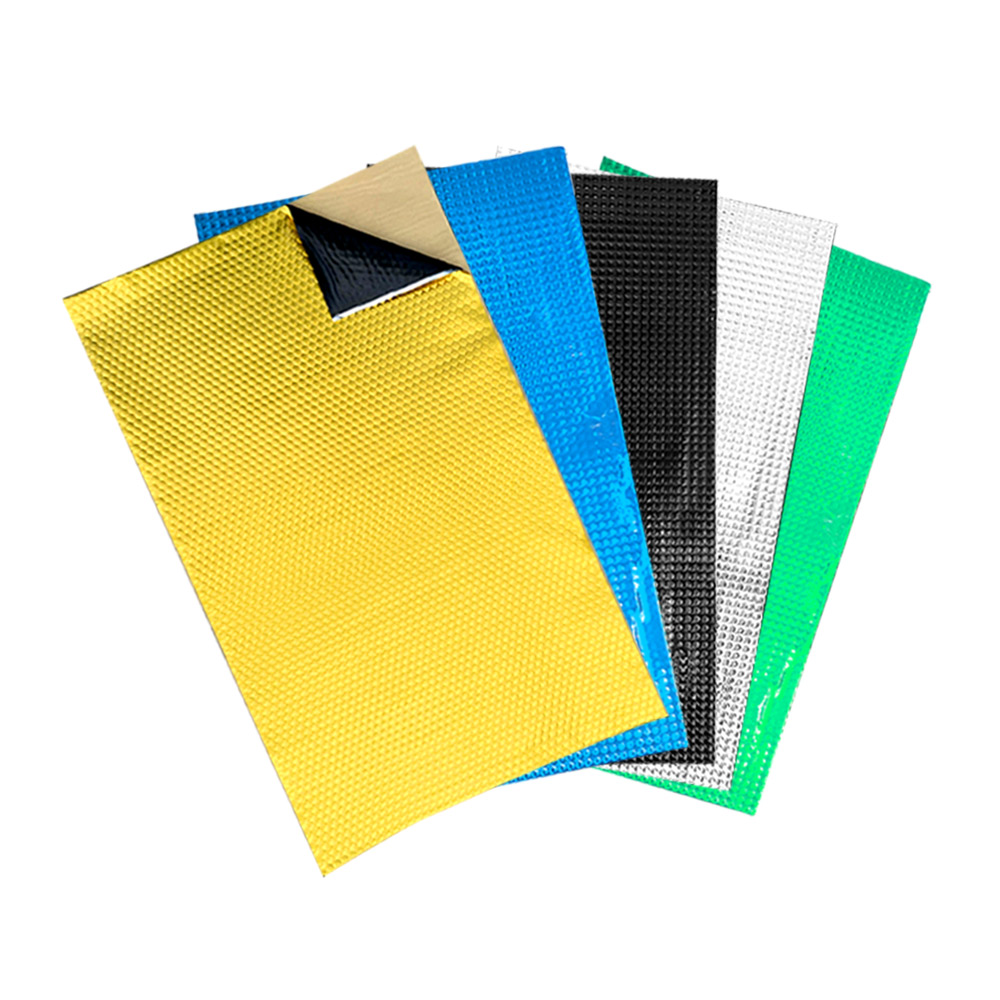

- Product overview — butyl rubber sheet and ASLONG Butyl Rubber Sound Damping Mat

- What is a Butyl Rubber Sound Damping Mat (butyl rubber sheet)?

- Core technical specifications buyers must check for any butyl rubber sheet

- 1. Thickness options (mm)

- 2. Areal density / weight (kg/m²)

- 3. Damping/loss factor (mechanical loss factor, η)

- 4. Adhesive type and peel strength

- 5. Tensile strength and elongation at break

- 6. Operating temperature range

- 7. Corrosion and chemical compatibility

- 8. Fire and smoke ratings

- 9. VOCs and environmental compliance

- Performance comparison: Butyl rubber sheet versus other damping options

- Installation best practices for a butyl rubber sheet

- Buying checklist: questions to ask your supplier about butyl rubber sheet

- Environmental, safety, and regulatory considerations for buyers

- When to choose ASLONG Butyl Rubber Sound Damping Mat

- ASLONG advantages summarized

- Practical examples: where butyl rubber mats improve real-world noise problems

- Cost-benefit considerations and lifecycle

- FAQ — Common questions about Butyl Rubber Sound Damping Mat (butyl rubber sheet)

- Q: How is butyl rubber different from asphalt sound deadeners?

- Q: Can I use butyl mats on painted surfaces?

- Q: Will a butyl mat stop airborne noise or just vibration?

- Q: Do butyl mats require special tools for installation?

- Q: Are butyl mats recyclable?

- Q: What tests should I request to evaluate a mat?

- Contact ASLONG or view product — next steps

- Authoritative references and further reading

Butyl Rubber Sound Damping Mat: Technical Specs Buyers Need

Product overview — butyl rubber sheet and ASLONG Butyl Rubber Sound Damping Mat

ASLONG Butyl Rubber Sound Damping Mat for sale. Effectively reduces noise and vibrations. High-quality butyl rubber ensures superior performance and durability. Ideal for automotive, industrial, and home applications.

This article explains, in practical terms, which technical specifications matter when choosing a butyl rubber sheet (Butyl Rubber Sound Damping Mat) so you can compare products, ensure correct performance for your application, and avoid common purchase mistakes.

What is a Butyl Rubber Sound Damping Mat (butyl rubber sheet)?

A Butyl Rubber Sound Damping Mat is a viscoelastic sheet designed to absorb and dissipate vibrational energy from panels, enclosures, and structures. The mat usually combines a butyl rubber layer (viscoelastic material) with a factory-applied pressure-sensitive adhesive backing for direct application to metal, composites, or certain plastics.

Key functional roles:

- Reduce structural vibration and resonant amplification (panel ringing).

- Lower interior noise by improving damping and reducing sound radiation from panels.

- Provide minor mass-loading to shift resonant frequencies when combined with other materials.

Core technical specifications buyers must check for any butyl rubber sheet

When evaluating Butyl Rubber Sound Damping Mat options, request and compare the following specifications from suppliers. These determine both performance and suitability for specific uses (automotive, industrial equipment, appliances, or home soundproofing).

1. Thickness options (mm)

Common thicknesses: 1.5 mm, 2.0 mm, 3.0 mm, 4.0 mm, 5.0 mm. Thicker mats generally provide greater damping and some mass effect, but add weight and can be harder to fit in tight cavities. Choose thickness according to application — for example, 2–3 mm for doors and roofs, 3–5 mm for floors and heavy panels.

2. Areal density / weight (kg/m²)

Areal density affects the mass-loading effect and ease of handling. Many butyl damping mats are supplied by thickness rather than strict areal density, but ask for kg/m² if mass addition matters for your design. Typical mats range from ~2.5 to 6.0 kg/m² depending on thickness and formulation.

3. Damping/loss factor (mechanical loss factor, η)

The loss factor indicates how effectively the material converts vibrational energy into heat. Suppliers sometimes present this as a curve vs frequency and temperature. Typical viscoelastic damping layers will have loss factors in a usable range (e.g., 0.1–0.6) within the product’s operating temperature. Ask for test curves or lab data covering the frequency band important for your application (e.g., 20–2000 Hz for automotive NVH).

4. Adhesive type and peel strength

Most mats come with a pressure-sensitive adhesive (PSA) backing protected by a release liner. Key numbers: peel strength (N/cm) and tack at ambient and cold temperatures. Good adhesion prevents delamination. Typical peel strength values are manufacturer-specific; verify adhesion to your substrate (painted panels, galvanized steel, aluminum, composites).

5. Tensile strength and elongation at break

These mechanical properties indicate resistance to tearing during handling and installation. Typical ranges: tensile strength of several MPa and elongation at break often >100–200%. Exact values vary by formulation.

6. Operating temperature range

Butyl-based mats are valued for broad temperature stability. Common operating ranges: -40°C to +100–120°C. Verify the adhesive and backing performance across your expected service temperatures, especially for under-hood or high-temperature industrial environments.

7. Corrosion and chemical compatibility

Butyl rubber is chemically stable, but adhesives and fillers can affect corrosion behavior when adhered to untreated steel. Confirm anti-corrosion compatibility and, if necessary, request coated or non-corrosive adhesive options for long-term applications.

8. Fire and smoke ratings

For building, rail, or aerospace use, fire performance matters. Ask for UL, FMVSS (for some automotive requirements), or specific flammability ratings. For general automotive and industrial use, materials are often formulated to meet self-extinguishing or low-flame-spread criteria.

9. VOCs and environmental compliance

Buyers should confirm VOC content and request REACH and RoHS compliance where applicable. Low-VOC formulations are preferred for interior applications to reduce odor and off-gassing.

Performance comparison: Butyl rubber sheet versus other damping options

Below is a practical comparison to help you weigh butyl mats against asphalt-based deadeners, foam absorbers, and mass-loaded vinyl (MLV).

| Property / Material | Butyl Rubber Sheet (Butyl Mat) | Asphalt-Based Deadener | Foam Absorber | Mass-Loaded Vinyl (MLV) |

|---|---|---|---|---|

| Damping (viscoelastic) | Excellent — designed to absorb panel vibration | Good — heavy, dampens some vibration but can harden | Fair — absorbs airborne noise, limited structural damping | Fair–Good — adds mass to block sound, less viscoelastic damping |

| Adhesion & ease of install | Very good with PSA backing; requires roller | Good but can be messy and heavy | Easy — often contoured foam panels or spray | Moderate — heavy and requires sealing edges |

| Temperature stability | High — wide temp range (-40 to 100+ °C) | Moderate — can bleed at high temp | Variable — many foams degrade with heat | Good — polymeric but may stiffen in cold |

| Corrosion risk | Low (formulations available to minimize corrosivity) | Higher — asphalt can trap moisture and corrode | Low | Low |

| Weight / volume | Moderate | High | Low | High (high mass per area) |

| Typical best uses | Automotive panels, doors, roofs, industrial housings | Large flat panels where mass is acceptable | HVAC ducts, irregular cavities for airborne noise | Sound barriers, walls needing mass for airborne noise |

| Cost | Moderate | Lower (but heavier) | Low–Moderate | Higher |

Installation best practices for a butyl rubber sheet

Proper installation maximizes damping performance and product life. Follow these steps:

- Surface preparation: Clean surface of oil, dirt, rust, and loose paint. Use isopropyl alcohol or recommended cleaner. For painted surfaces, ensure paint has cured.

- Cut to size: Use a utility knife or shears. Pre-fit panels before removing release liner.

- Adhesion activation: For cold climates, warm the mat (or surface) slightly to improve tack; some mats bond better with light heating via heat gun.

- Apply and roll: Press on and roll from center to edges with a hand roller to remove air and ensure full contact.

- Edge sealing: Overlap seams minimally or use seam sealer if moisture ingress is a concern.

- Allow cure: Let adhesive set per manufacturer recommendations before subjecting to heavy loads or moisture.

Buying checklist: questions to ask your supplier about butyl rubber sheet

Before purchasing, request the following from any supplier:

- Technical Data Sheet (TDS) and Safety Data Sheet (SDS).

- Loss factor vs frequency and temperature curves, if available.

- Adhesive properties: peel strength, shear resistance, temperature-dependent tack.

- Available thicknesses, roll dimensions, and weight per roll.

- Fire rating, VOC content, and any certifications (REACH, RoHS, ISO 9001).

- Long-term aging data or accelerated weathering results.

- Sample availability for fit and adhesion testing.

Environmental, safety, and regulatory considerations for buyers

Buyers should confirm compliance with regional regulations: REACH compliance in Europe, RoHS where applicable, and any building code requirements for fire and smoke. For interior automotive and home uses, low-VOC products reduce odor and occupant exposure. Dispose of scrap per local regulations; butyl rubber is not readily biodegradable but can be recycled in some programs.

When to choose ASLONG Butyl Rubber Sound Damping Mat

Choose ASLONG's Butyl Rubber Sound Damping Mat when you need:

- Consistent viscoelastic damping across a wide temperature range.

- Strong, reliable adhesive backing for long-term bonding to metal and composite substrates.

- Multiple thickness options to tailor damping and mass-loading simultaneously.

- Low corrosion risk compared with asphalt-based alternatives.

ASLONG advantages summarized

ASLONG leverages material formulation and quality controls to deliver butyl rubber sheets that balance damping performance, adhesion, temperature stability, and manufacturability. Key advantages:

- Quality-assured manufacturing with TDS and SDS for engineering validation.

- Multiple product sizes and thicknesses for vehicle, appliance, and industrial use.

- Low-VOC formulations and options designed to minimize corrosion concerns.

- Support for samples and technical data to help OEMs and installers qualify the mat for specific NVH requirements.

Practical examples: where butyl rubber mats improve real-world noise problems

Examples where a butyl rubber sheet produces measurable benefits:

- Automotive: Door panels and rear decks — reduces wind and road-induced panel vibration and improves perceived cabin quietness.

- Home appliances: Washer/dryer and HVAC housings — reduces mechanical vibration transmitted to the home structure.

- Industrial equipment: Motor enclosures and chassis panels — lowers radiated noise and prolongs component life by damping vibration.

- Audio equipment racks: Prevents panel resonance that colors sound reproduction.

Cost-benefit considerations and lifecycle

While butyl mats are higher in cost than some simple foam materials, their superior damping often reduces the need for additional layers or modifications. Consider lifecycle costs: reduced warranty claims from vibration-related failures, improved product perception (quieter vehicles/appliances), and lower likelihood of corrosion compared with asphalt-based deadeners.

FAQ — Common questions about Butyl Rubber Sound Damping Mat (butyl rubber sheet)

Q: How is butyl rubber different from asphalt sound deadeners?

A: Butyl rubber is a viscoelastic polymer delivering long-term damping and better temperature stability. Asphalt deadeners are heavier and can harden, lose adhesion, or promote corrosion over time.

Q: Can I use butyl mats on painted surfaces?

A: Yes — but ensure the paint is fully cured, clean, and free of contaminants. Verify compatibility with the supplier and test adhesion on a sample area.

Q: Will a butyl mat stop airborne noise or just vibration?

A: Butyl mats primarily reduce panel vibration (structural-borne noise). For airborne noise, combine with absorptive materials (foam) or mass barriers (MLV) as needed.

Q: Do butyl mats require special tools for installation?

A: Basic tools (utility knife, measuring tools, hand roller) suffice. A heat gun or infrared heater can help adhesion in cold conditions.

Q: Are butyl mats recyclable?

A: Butyl rubber is not biodegradable. Scrap recycling depends on local facilities; consult supplier for take-back or recycling options.

Q: What tests should I request to evaluate a mat?

A: Ask for TDS, loss factor vs frequency, peel strength, temperature range, and any fire or VOC certifications. Request a sample for on-substrate testing.

Contact ASLONG or view product — next steps

If you are ready to evaluate ASLONG Butyl Rubber Sound Damping Mat for your project, request technical data sheets, sample kits for adhesion and fit testing, or a formal quote. Contact our sales team for customized roll sizes, thickness options, and certification documentation.

Contact our sales team for samples and pricing, or view the ASLONG Butyl Rubber Sound Damping Mat product page to download datasheets and order sample rolls.

Authoritative references and further reading

For engineering and regulatory context, see the following authoritative sources:

- Butyl rubber — Wikipedia: https://en.wikipedia.org/wiki/Butyl_rubber

- Soundproofing — Wikipedia: https://en.wikipedia.org/wiki/Soundproofing

- Acoustical Society of America — resources on noise control: https://acousticalsociety.org/

- ISO standards overview (acoustics and building): https://www.iso.org/ics/17.240.10/x/

- European Chemicals Agency — REACH regulations: https://echa.europa.eu/regulations/reach/understanding-reach

These sources provide background on material properties, acoustics principles, and regulatory frameworks that support rigorous product selection and specification.

Last updated by ASLONG technical editorial team — DT: please request current TDS for the exact product SKU prior to specification and purchase.

What are the different types of sound insulation building materials?

Quality Assurance and Testing Standards for NBR Foam

Top lightweight automotive sound insulation materials

How to manufacturing acoustic isolation material

FAQs

What specific functions can ASLONG's products provide?

Our products cover functions such as insulation, sound insulation, shock absorption, waterproofing and sealing, and are widely used in improving energy efficiency, reducing noise, controlling vibration, protecting equipment, etc., helping customers optimize engineering effects and improve user experience.

What industries are the products provided by ASLONG suitable for?

ASLONG's products are suitable for multiple industries, including air conditioning and HVAC, construction and waterproofing, automobiles and transportation, home appliances and electronics, industrial equipment and machinery, etc. We provide customized solutions for each industry to meet different needs.

Do ASLONG's products meet environmental protection standards?

Yes, all ASLONG products comply with ISO14001 environmental management system certification and global environmental protection standards. We use environmentally friendly materials and are committed to providing sustainable solutions to help customers achieve green development goals.

Does ASLONG provide after-sales service?

Yes, we provide a full range of after-sales services, including technical support, installation guidance, product maintenance and quality tracking, etc., to ensure that each project goes smoothly and continues to perform at its best.

How to customize products that meet the needs of my industry?

You only need to contact our sales or technical team, we will conduct an in-depth analysis based on your industry needs and provide tailor-made products and solutions. We guarantee to provide you with efficient and accurate services to meet your personalized requirements.

Butyl Rubber Sound Damping Mat

ASLONG Butyl Rubber Sound Damping Mat for sale. Effectively reduces noise and vibrations. High-quality butyl rubber ensures superior performance and durability. Ideal for automotive, industrial, and home applications.

Mass Loaded Vinyl

ASLONG Mass Loaded Vinyl for sale. Reduce noise pollution effectively with our high-quality, mass-loaded vinyl. Ideal for soundproofing walls, floors, and more. Buy now and experience the difference!

Egg Crate Foam

ASLONG Egg Crate Foam for sale. Lightweight, breathable, and comfortable, our egg crate foam provides superior support and pressure relief. Perfect for mattresses, cushions, cars, construction industry, KTV, factories, etc.

NBR Foam

ASLONG NBR Foam: Wholesale NBR foam solutions for diverse applications. High-quality, durable, and competitively priced. Contact us today for bulk orders.

Professional support at any time

If you have any comments or good suggestions, please leave us a message; later our professional staff will contact you as soon as possible.

© 2026 ASLONG All Rights Reserved. Privacy Policy | Terms and Conditions | Sitemap

Whatsapp: +8613242879341

ASLONG Global

ASLONG

Aslong_global