Best applications for Butyl Rubber Sheet in vehicles and buildings

- What is a butyl rubber sheet and why choose a Butyl Rubber Sound Damping Mat?

- Primary benefits of butyl rubber sheet in acoustic and vibration control (includes keywords)

- Best vehicle applications for Butyl Rubber Sound Damping Mat (buy butyl rubber sheet for vehicles)

- Practical vehicle installation tips (purchase butyl rubber sheet and install)

- Best building applications for Butyl Rubber Sound Damping Mat (butyl rubber sheet for buildings)

- Building installation considerations (buy butyl rubber sheet for retrofit projects)

- How Butyl Rubber Sound Damping Mat compares to other damping materials (butyl vs alternatives)

- Performance metrics, testing, and what to expect (buyers considering butyl rubber sheet)

- Installation best practices and troubleshooting (buy butyl rubber sound damping mat for sale — installation)

- Durability, environmental resistance, and maintenance (butyl rubber sheet lifecycle)

- Cost-effectiveness and ROI (purchase butyl rubber sheet — long-term benefits)

- Brand summary: Why choose ASLONG Butyl Rubber Sound Damping Mat?

- FAQ — Frequently Asked Questions about Butyl Rubber Sheet and ASLONG Butyl Rubber Sound Damping Mat

- Q: What makes butyl rubber preferable to bitumen-based damping mats?

- Q: Can I use butyl rubber sheets under flooring to reduce impact noise?

- Q: Are butyl damping mats safe for automotive interiors (odor, toxicity)?

- Q: How do I select the right thickness and coverage?

- Q: Will adding butyl mats increase vehicle weight significantly?

- Contact / View product (CTA)

- References and authoritative sources

What is a butyl rubber sheet and why choose a Butyl Rubber Sound Damping Mat?

Butyl rubber is a synthetic elastomer known for low gas permeability, excellent damping properties, and weather resistance. A butyl rubber sheet is a flexible, dense sheet used for sealing, vibration control, and acoustic damping. The commercial product ASLONG Butyl Rubber Sound Damping Mat combines these properties into a purpose-built damping mat designed to reduce airborne noise and structure-borne vibrations in vehicles, industrial equipment, and buildings. Once application scenarios are clear, it becomes important to understand performance fundamentals, including how Butyl Rubber Sound Damping Mat reduces vibrations and road noise. Once application scenarios are clear, it becomes important to understand performance fundamentals, including how Butyl Rubber Sound Damping Mat reduces vibrations and road noise.

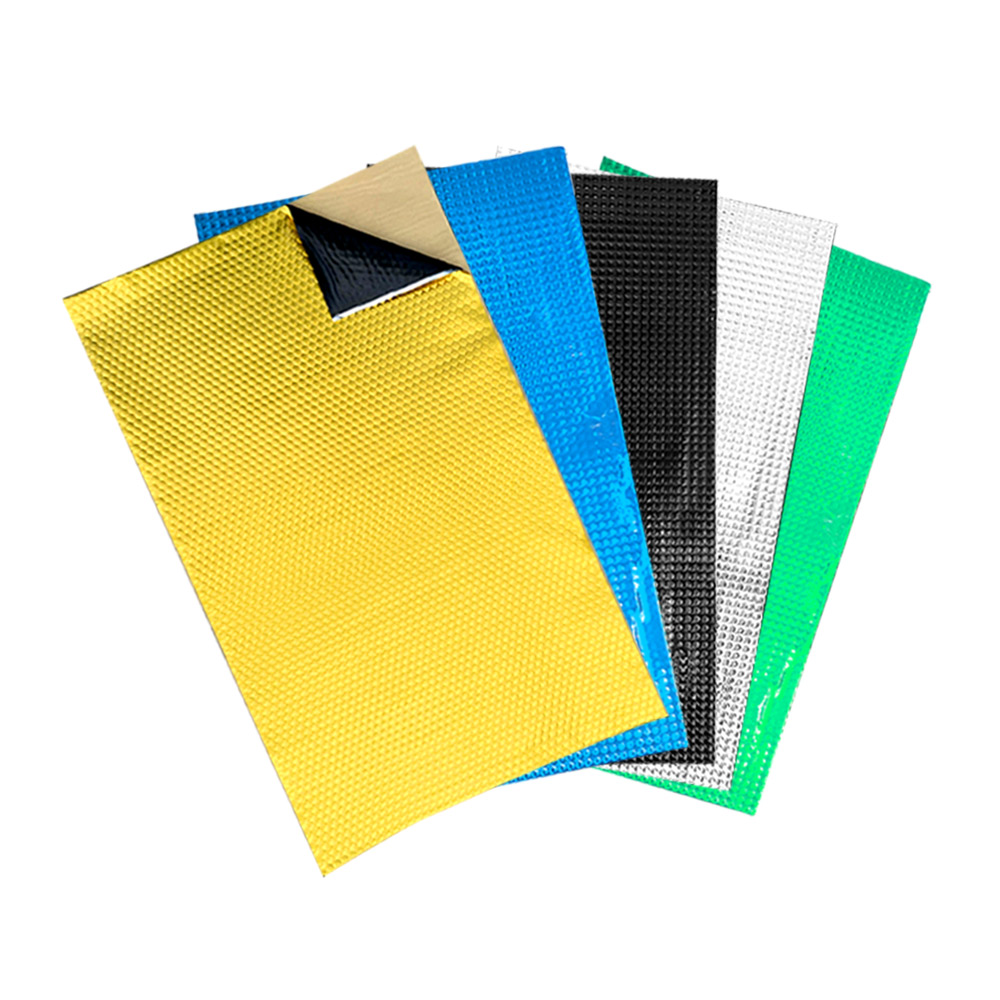

Product highlight:

ASLONG Butyl Rubber Sound Damping Mat for sale. Effectively reduces noise and vibrations. High-quality butyl rubber ensures superior performance and durability. Ideal for automotive, industrial, and home applications.

Primary benefits of butyl rubber sheet in acoustic and vibration control (includes keywords)

When choosing a butyl rubber sheet or butyl rubber sound damping mat for sale, buyers typically seek improved acoustic comfort, reduced rattles and resonance, long-term durability, and simple installation. Butyl rubber excels at converting vibrational energy into heat (damping), blocking transmission paths, and maintaining performance across a wide temperature range. This makes it an ideal material when you decide to buy butyl rubber sheet for vehicle upgrades or building retrofits.

Best vehicle applications for Butyl Rubber Sound Damping Mat (buy butyl rubber sheet for vehicles)

Automotive noise control is one of the most common uses for butyl rubber sheets. Installing a butyl rubber sound damping mat in key vehicle areas reduces road noise, engine/motor vibrations, and panel resonance. The most effective locations include:

- Doors and inner door skins — Damping mats on door skins stop panel buzz and reduce wind and tire noise transmitted into the cabin.

- Floors and transmission tunnels — Floor mats reduce low-frequency road and drivetrain vibrations, improving NVH (noise, vibration, harshness).

- Trunk floors and spare wheel wells — Trunk areas often act as resonant cavities; damping reduces booming and rattles.

- Roof and headliner sections — Roof damping reduces wind noise and rain impact noise.

- Hood and firewall — Engine bay damping helps reduce engine noise entering the cabin.

- Wheel arches and underbody panels — Damping here cuts tire roar and stone impacts.

Practical vehicle installation tips (purchase butyl rubber sheet and install)

For best results, clean and degrease surfaces, apply at manufacturer-recommended temperatures, use medium pressure rollers to ensure full contact, and overlap seams slightly. For door skins, partial coverage focused on central panel areas often gives the biggest noise reduction per weight. For floors, use a combination of butyl damping mats and a top layer of mass or foam where additional airborne insulation is needed.

Best building applications for Butyl Rubber Sound Damping Mat (butyl rubber sheet for buildings)

In buildings, butyl rubber sheets are used to control vibration from mechanical systems and to improve acoustic privacy. Typical applications include:

- Mechanical rooms and equipment bases — Place butyl mats under compressors, pumps, HVAC units, and generators to reduce transmitted vibration to the structure.

- Floors (between structure and finish) — As a damping layer beneath floor finishes, butyl mats reduce impact and structure-borne noise, especially in renovation projects where adding heavy mass is impractical.

- Partition walls and ceiling assemblies — Embedded as a damping layer in metal stud partitions or ceiling plenum panels to reduce flanking paths.

- HVAC duct lining and junctions — Damp vibrating duct panels; combined with insulation, they lower breakout noise.

- Window frames and door thresholds — Thin butyl strips provide sealing and vibration isolation for acoustically sensitive rooms.

Building installation considerations (buy butyl rubber sheet for retrofit projects)

For retrofit noise control, butyl damping mats are favored because they add minimal thickness while delivering effective damping. Ensure substrate is dry, free of dust and insulation fibers, and that mating surfaces are rigid enough to transmit vibrational energy into the damping layer. For floor applications, combine butyl damping mats with a separate airborne barrier (e.g., mineral wool or mass-loaded vinyl) to address both structure-borne and airborne sound.

How Butyl Rubber Sound Damping Mat compares to other damping materials (butyl vs alternatives)

When choosing materials, compare damping efficiency, added mass, durability, ease of installation, and cost. The table below summarizes common trade-offs.

| Material | Primary function | Damping effectiveness | Weight/Thickness | Installation ease | Typical uses |

|---|---|---|---|---|---|

| Butyl Rubber Sheet (ASLONG) | Vibration damping & sealing | High (excellent loss factor at low-mid frequencies) | Low–medium | Very good (peel-and-stick variants) | Vehicle panels, equipment bases, retrofit floors |

| Bitumen damping mats | Mass + damping | Medium–high (heavy) | High (adds mass) | Moderate (cold or heat-activated) | Automotive floors, trunk, heavy panels |

| Mass-Loaded Vinyl (MLV) | Airborne sound barrier | Low damping, high mass | High (dense) | Moderate | Partitions, ceilings, floors for airborne sound |

| Acoustic foam | Absorption (airborne mid-high freq) | Low for structure-borne | Low | Easy | Room acoustics, HVAC plenums |

| Neoprene isolation pads | Vibration isolation | Good for narrow frequency ranges | Varies | Easy | Machinery mounts, equipment bases |

Performance metrics, testing, and what to expect (buyers considering butyl rubber sheet)

Key metrics to evaluate include sound transmission loss, impact on STC (Sound Transmission Class), reduction in dB for target frequencies, and vibration transmissibility. Butyl rubber damping mats primarily improve structure-borne attenuation and reduce resonant peaks; they typically yield the largest perceived benefit in 20–4000 Hz range where panels resonate.

Industry standards that describe measurement methods include ASTM E90 (laboratory measurement of airborne sound transmission loss) and ISO 140/717 family (building acoustics). For vehicles, NVH performance is usually measured with modal analysis and in-cabin noise testing. When buying butyl rubber mats for vehicles or buildings, request product-specific test data showing dB reductions at representative frequencies or STC improvements for assemblies.

Installation best practices and troubleshooting (buy butyl rubber sound damping mat for sale — installation)

For durable, high-performance results:

- Always clean surfaces: remove grease, adhesives, and corrosion.

- Work temperature: apply above the recommended minimum (typically 10–15°C for self-adhesive mats) to ensure good adhesion.

- Use a roller: a 50–100 mm roller with firm pressure eliminates air pockets and ensures full contact.

- Layering strategy: for best acoustic performance combine butyl damping layers with a separate mass layer (MLV) or absorptive layer depending on whether airborne or structure-borne noise is dominant.

- Edge sealing: overlap or seal edges to eliminate flanking and moisture ingress.

Troubleshooting common issues: adhesion failures are usually due to surface contamination or cold application temperatures; persistent resonance after application may indicate insufficient coverage of critical panel modes and may be addressed by adding patches at anti-nodal areas identified via simple tapping tests or more detailed modal testing.

Durability, environmental resistance, and maintenance (butyl rubber sheet lifecycle)

Butyl rubber resists aging, ozone, and many chemicals better than natural rubbers and bitumen. It maintains damping properties over wide temperature ranges and typically outlasts asphalt-based damping mats in outdoor or high-moisture environments. Maintenance is minimal: keep surfaces clean, inspect adhesive edges occasionally, and re-secure or replace panels exposed to mechanical damage.

Cost-effectiveness and ROI (purchase butyl rubber sheet — long-term benefits)

Although high-quality butyl products can be more expensive per square meter than some alternatives, their combination of thin profile, high damping efficiency, ease of installation, and long service life often yields better value in retrofit situations where added thickness or weight is constrained. For vehicles, improved NVH can increase perceived quality and resale value. In buildings, reduced noise transmission can raise tenant satisfaction and reduce complaints.

Brand summary: Why choose ASLONG Butyl Rubber Sound Damping Mat?

ASLONG Butyl Rubber Sound Damping Mat for sale is positioned as a high-quality solution for both automotive and building applications. Key brand advantages include:

- Designed specifically for acoustic and vibration control with reliable damping performance.

- Durable butyl compound that resists aging, moisture, and temperature cycling.

- Easy-to-install formats (peel-and-stick options) for fast retrofit or production-line application.

- Suitable for a broad set of use cases—automotive NVH, industrial machinery isolation, and building retrofit sound control.

FAQ — Frequently Asked Questions about Butyl Rubber Sheet and ASLONG Butyl Rubber Sound Damping Mat

Q: What makes butyl rubber preferable to bitumen-based damping mats?

A: Butyl rubber typically offers better long-term elasticity, lower odor, resistance to cold cracking, and better resistance to environmental degradation. It provides efficient damping at lower thickness and weight compared to many bitumen mats.

Q: Can I use butyl rubber sheets under flooring to reduce impact noise?

A: Yes. Butyl rubber mats are effective at reducing structure-borne vibrations from impact events. For maximum airborne reduction, combine with a separate mass or absorption layer depending on the target frequencies.

Q: Are butyl damping mats safe for automotive interiors (odor, toxicity)?

A: High-quality butyl products designed for interiors have low VOC and low odor. Always verify manufacturer specifications or third-party test results for VOC compliance if indoor air quality is a concern.

Q: How do I select the right thickness and coverage?

A: Selection depends on the panel material and target frequencies. For thin metal panels, localized patches (100–500 cm² at anti-nodes) or 1–2 mm continuous coverage can yield strong improvements. For floors or heavy equipment, thicker or layered solutions may be better. Contact technical sales for application-specific guidance.

Q: Will adding butyl mats increase vehicle weight significantly?

A: Butyl mats are designed to be light relative to equivalent mass-based solutions. When applied selectively (targeted patches or limited coverage), the weight penalty is minimal compared to the acoustic benefits.

Contact / View product (CTA)

If you would like to evaluate ASLONG Butyl Rubber Sound Damping Mat for your vehicle or building project, contact our sales team or view product specifications and availability. Our technical specialists can recommend coverage, thickness, and application methods tailored to your needs. Contact us today to request samples, datasheets, or installation guides.

References and authoritative sources

Below are authoritative resources referenced for material properties, acoustic standards, and general background:

- Butyl rubber — Wikipedia: https://en.wikipedia.org/wiki/Butyl_rubber

- Soundproofing — Wikipedia: https://en.wikipedia.org/wiki/Soundproofing

- Sound transmission class (STC) — Wikipedia: https://en.wikipedia.org/wiki/Sound_transmission_class

- ASTM E90 — Standard Test Method for Laboratory Measurement of Airborne Sound Transmission Loss of Building Partitions and Elements: https://www.astm.org/e0090-17.

- ISO 717 — Acoustics — Rating of sound insulation in buildings and of building elements: https://www.iso.org/standard/37191.

- Mass-loaded vinyl — Wikipedia: https://en.wikipedia.org/wiki/Mass-loaded_vinyl

- Acoustical Society of America — general resource on acoustic science: https://acousticalsociety.org/

How to manufacturing waterproof butyl tape

Top Sound Insulation Brands for Automotive Use 2026

Tips for buy auto sound deadening material

Top 10 nitrile butadiene rubber nbr foam product Manufacturers and Supplier Brands

FAQs

Do ASLONG's products meet environmental protection standards?

Yes, all ASLONG products comply with ISO14001 environmental management system certification and global environmental protection standards. We use environmentally friendly materials and are committed to providing sustainable solutions to help customers achieve green development goals.

Does ASLONG provide after-sales service?

Yes, we provide a full range of after-sales services, including technical support, installation guidance, product maintenance and quality tracking, etc., to ensure that each project goes smoothly and continues to perform at its best.

What industries are the products provided by ASLONG suitable for?

ASLONG's products are suitable for multiple industries, including air conditioning and HVAC, construction and waterproofing, automobiles and transportation, home appliances and electronics, industrial equipment and machinery, etc. We provide customized solutions for each industry to meet different needs.

What specific functions can ASLONG's products provide?

Our products cover functions such as insulation, sound insulation, shock absorption, waterproofing and sealing, and are widely used in improving energy efficiency, reducing noise, controlling vibration, protecting equipment, etc., helping customers optimize engineering effects and improve user experience.

How to customize products that meet the needs of my industry?

You only need to contact our sales or technical team, we will conduct an in-depth analysis based on your industry needs and provide tailor-made products and solutions. We guarantee to provide you with efficient and accurate services to meet your personalized requirements.

Butyl Rubber Sound Damping Mat

ASLONG Butyl Rubber Sound Damping Mat for sale. Effectively reduces noise and vibrations. High-quality butyl rubber ensures superior performance and durability. Ideal for automotive, industrial, and home applications.

Mass Loaded Vinyl

ASLONG Mass Loaded Vinyl for sale. Reduce noise pollution effectively with our high-quality, mass-loaded vinyl. Ideal for soundproofing walls, floors, and more. Buy now and experience the difference!

Egg Crate Foam

ASLONG Egg Crate Foam for sale. Lightweight, breathable, and comfortable, our egg crate foam provides superior support and pressure relief. Perfect for mattresses, cushions, cars, construction industry, KTV, factories, etc.

NBR Foam

ASLONG NBR Foam: Wholesale NBR foam solutions for diverse applications. High-quality, durable, and competitively priced. Contact us today for bulk orders.

Professional support at any time

If you have any comments or good suggestions, please leave us a message; later our professional staff will contact you as soon as possible.

© 2026 ASLONG All Rights Reserved. Privacy Policy | Terms and Conditions | Sitemap

Whatsapp: +8613242879341

ASLONG Global

ASLONG

Aslong_global