Car Soundproofing Installation Techniques | How to Reduce Vehicle Noise Effectively

Learn professional car soundproofing installation techniques to reduce road noise, vibration, and improve driving comfort. A complete guide to automotive sound insulation.

- Car Soundproofing Installation Techniques: A Practical Guide for Better Driving Comfort

- Why Proper Soundproofing Installation Matters

- Common Noise Sources in Vehicles

- Step-by-Step Car Soundproofing Installation Tips

- 1. Surface Preparation Is Critical

- 2. Apply Sound Deadening Materials Strategically

- 3. Door Soundproofing Techniques

- 4. Floor and Firewall Installation

- 5. Trunk and Wheel Arch Treatment

- 6. Use the Right Tools

- Common Installation Mistakes to Avoid

Car Soundproofing Installation Techniques: A Practical Guide for Better Driving Comfort

Excessive road noise, engine vibration, and wind sound can significantly reduce driving comfort. Proper car soundproofing installation is not only about choosing the right materials, but also about applying them correctly. This guide explains proven automotive sound insulation construction techniques to help achieve the best noise reduction results.

Why Proper Soundproofing Installation Matters

Even high-quality sound deadening materials can underperform if installed incorrectly. Correct installation ensures:

-

Maximum noise reduction efficiency

-

Improved driving comfort and audio quality

-

Long-lasting adhesion and durability

-

Better thermal insulation as a bonus

Understanding where and how to apply soundproofing materials is the key to success.

Common Noise Sources in Vehicles

Before installation, it is important to identify noise entry points:

-

Doors: wind noise, speaker vibration

-

Floor & firewall: road noise, tire noise, engine vibration

-

Roof: rain noise, heat transfer

-

Trunk & wheel arches: tire and exhaust noise

Targeted installation improves results while reducing unnecessary material use.

Step-by-Step Car Soundproofing Installation Tips

1. Surface Preparation Is Critical

-

Clean metal surfaces thoroughly to remove dust, oil, and moisture

-

Dry the area completely before installation

-

Proper preparation improves adhesive bonding and prevents peeling

2. Apply Sound Deadening Materials Strategically

Soundproofing is most effective when layered correctly:

-

First layer: vibration-damping materials (butyl rubber or asphalt sheets)

-

Second layer: sound-absorbing foam or acoustic cotton

-

Third layer (optional): heat insulation or reflective materials

Focus on high-vibration zones rather than covering the entire surface blindly.

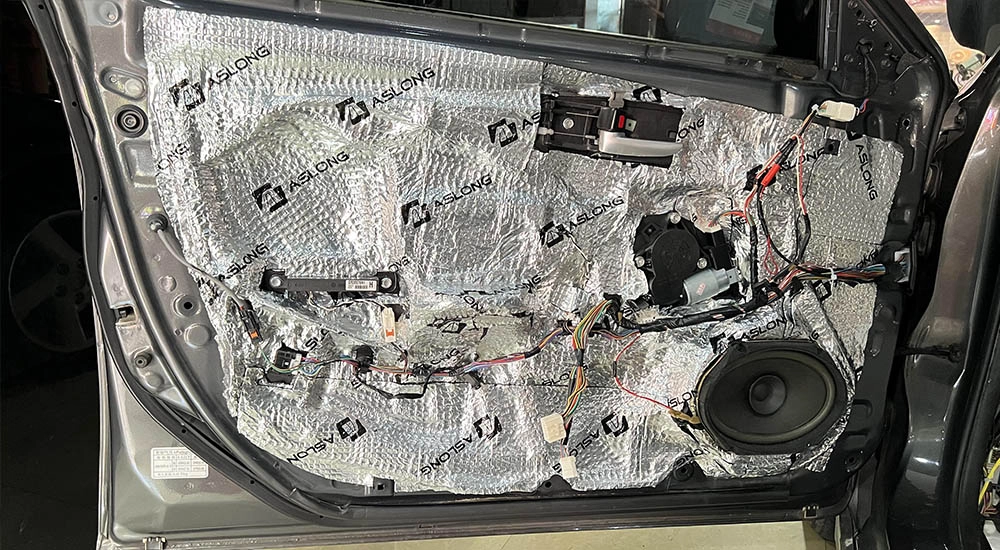

3. Door Soundproofing Techniques

-

Apply damping sheets to the outer door panel to reduce vibration

-

Seal service holes with aluminum-backed mats

-

Add foam or acoustic cotton on the inner panel to absorb mid- and high-frequency noise

This method also enhances speaker performance.

4. Floor and Firewall Installation

-

Cover large flat areas where road noise transfers directly into the cabin

-

Roll materials firmly to eliminate air bubbles

-

Avoid blocking drainage holes or wiring channels

-

Proper coverage here greatly reduces low-frequency noise.

5. Trunk and Wheel Arch Treatment

-

Use thicker sound insulation materials in these areas

-

Pay special attention to curved surfaces and seams

-

Ensure tight adhesion to prevent future detachment

This is especially effective for reducing tire and exhaust noise.

6. Use the Right Tools

-

Pressure rollers for firm bonding

-

Utility knives for precise cutting

-

Heat guns (if recommended) to improve flexibility and adhesion

Professional tools significantly improve installation quality.

-

-

Common Installation Mistakes to Avoid

-

Overlapping materials excessively, adding unnecessary weight

-

Ignoring small gaps where noise can leak

-

Installing on dirty or damp surfaces

-

Using only one type of material instead of layered solutions

Avoiding these mistakes can dramatically improve soundproofing performance.

The Complete Guide to Mass Loaded Vinyl 2026: Does MLV Work For Soundproofing?

High Performance Car Sound Deadening Material for Automotive Insulation

Does Installing Soundproofing Products Damage Your Vehicle?

The 10 Best Sound Absorbing Materials (2026): The Ultimate Buyer’s Guide to Professional Noise Control

OEM & Wholesale Car Sound Deadening Mat for All Vehicle Types | Automotive Noise Control Solutions

FAQs

Does ASLONG provide after-sales service?

Yes, we provide a full range of after-sales services, including technical support, installation guidance, product maintenance and quality tracking, etc., to ensure that each project goes smoothly and continues to perform at its best.

Do ASLONG's products meet environmental protection standards?

Yes, all ASLONG products comply with ISO14001 environmental management system certification and global environmental protection standards. We use environmentally friendly materials and are committed to providing sustainable solutions to help customers achieve green development goals.

What specific functions can ASLONG's products provide?

Our products cover functions such as insulation, sound insulation, shock absorption, waterproofing and sealing, and are widely used in improving energy efficiency, reducing noise, controlling vibration, protecting equipment, etc., helping customers optimize engineering effects and improve user experience.

How to customize products that meet the needs of my industry?

You only need to contact our sales or technical team, we will conduct an in-depth analysis based on your industry needs and provide tailor-made products and solutions. We guarantee to provide you with efficient and accurate services to meet your personalized requirements.

What industries are the products provided by ASLONG suitable for?

ASLONG's products are suitable for multiple industries, including air conditioning and HVAC, construction and waterproofing, automobiles and transportation, home appliances and electronics, industrial equipment and machinery, etc. We provide customized solutions for each industry to meet different needs.

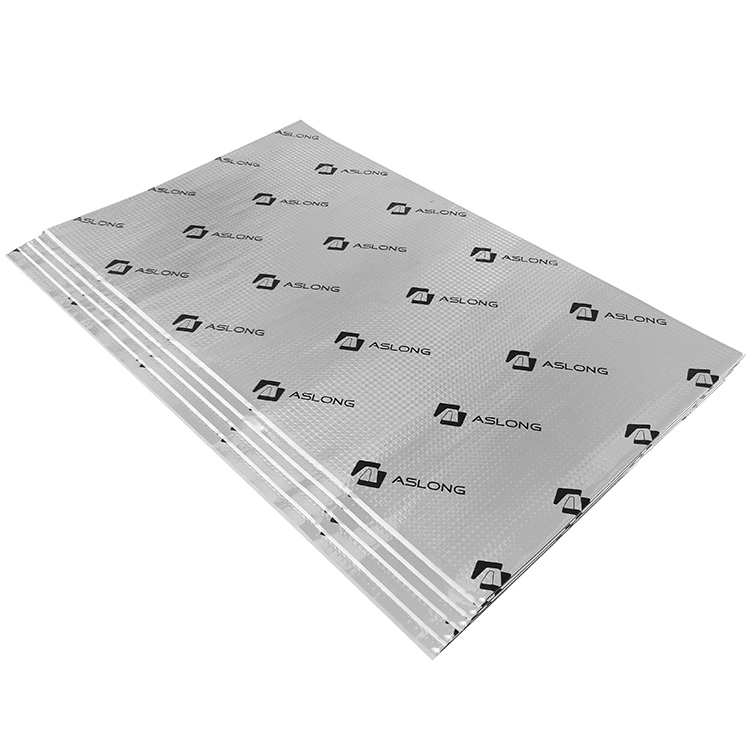

Aslong Professional Vibration Control Panel | Butyl-Based Automotive Sound Deadening Board with Aluminum Layer

ASLONG Butyl Rubber Sound Deadening Mat is designed to minimize structural noise caused by panel resonance and road vibration. Built with an elastic butyl compound and an aluminum-backed surface, it stabilizes vehicle body panels and transforms noisy metal surfaces into acoustically controlled structures. Ideal for OEM upgrades, car audio installations, and professional automotive soundproofing projects.

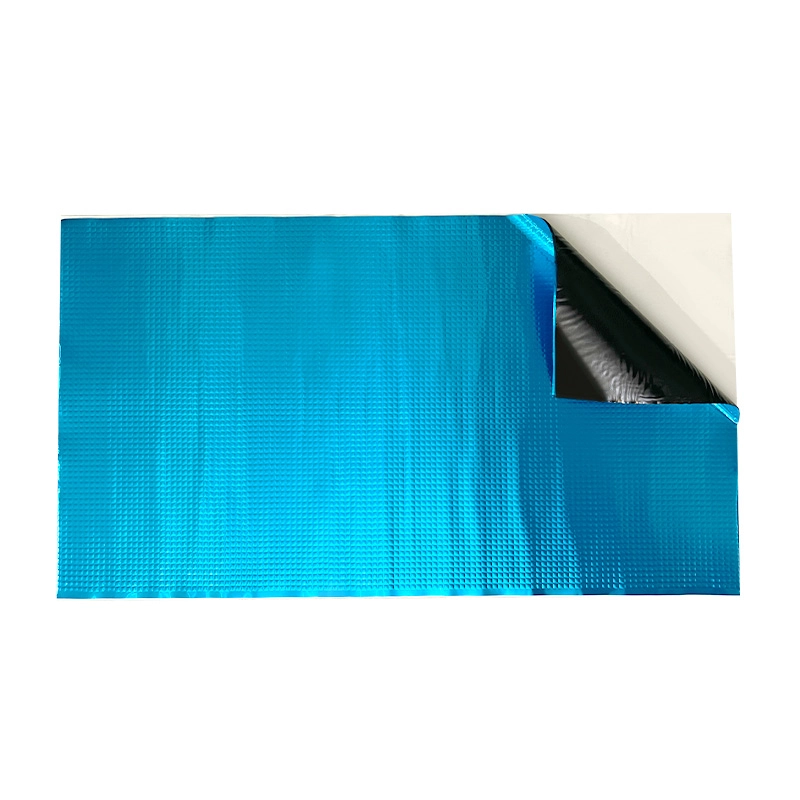

Aslong Dual-Layer Sound & Heat Insulation Mat | High-Density Butyl Deadening Sheet for Automotive Noise Control

The Aslong Sound & Heat Insulation Mat is engineered with a high-density butyl core and heat-resistant aluminum foil surface to provide reliable noise reduction and thermal protection. Designed to block road noise, engine heat, and vibration, it upgrades your vehicle’s comfort instantly. Strong adhesion ensures long-lasting performance in all climates.

Aslong Premium Sound Deadening Mat | Butyl Rubber & Aluminum Vibrations Dampening Pad for Automotive Noise Reduction

The Aslong Sound Deadening Mat is made from high-density butyl rubber combined with reinforced aluminum foil. It effectively reduces vehicle vibrations, eliminates resonance noise, and improves cabin comfort. Ideal for doors, floors, trunks, wheel arches, and engine hoods. Strong adhesion and easy installation make it suitable for both professionals and DIY users.

Butyl Rubber Sound Deadening Mat | Car Noise & Heat Insulation Aluminum Foil Pad | Automotive Soundproof & Thermal Barrier Material

Professional support at any time

Contact us for a free quote on our new soundproofing materials!

© 2026 ASLONG All Rights Reserved. Privacy Policy | Terms and Conditions | Sitemap

Whatsapp: +8613242879341

ASLONG Global

ASLONG

Aslong_global