The B2B Buyer’s Guide to Car Sound Deadener Mat

- What is a Car Sound Deadener Mat?

- Definition and commercial intent

- Why B2B Buyers Should Prioritize Sound Deadening

- Business benefits and ROI

- Common Types of Car Sound Deadener Mat

- Butyl Rubber Sound Damping Mat — the market workhorse

- Mass Loaded Vinyl (MLV) — for airborne noise control

- Open-cell and closed-cell foams — support and absorption

- Composite systems — layered solutions for best performance

- Key Technical Specs B2B Buyers Need to Compare

- Surface density and mass per unit area

- Loss factor and damping performance

- Thickness, conformability, and thermal limits

- Adhesive properties and long-term aging

- Performance Metrics and Testing to Request

- Acoustic test data you should require

- Environmental and regulatory compliance

- Installation Considerations for Supply Contracts

- Ease of installation and labor costs

- Surface prep, primers, and tooling

- Service life and maintenance

- Cost Considerations and Sourcing Strategies

- Unit cost vs. system cost

- Volume discounts, lead times, and supply resilience

- Why Choose ASLONG as Your Sound Deadener Mat Partner?

- Company strengths tailored for B2B procurement

- Global reach and OEM-ready capabilities

- Sustainability and compliance

- How to Evaluate Suppliers: A Practical Checklist

- Procurement checklist for Car Sound Deadener Mat

- Case Study Snapshot: Typical Fleet Upgrade Scenario

- Problem, solution, and result (concise commercial example)

- Packaging, Logistics, and Worldwide Distribution

- How packaging and logistics affect procurement

- Conclusion: How to Move Forward as a B2B Buyer

- Next steps to secure the right sound deadener mat

- Contact and Supplier Engagement

- How to contact ASLONG for B2B procurement

What is a Car Sound Deadener Mat?

Definition and commercial intent

A car sound deadener mat is a sheet or roll of material designed to reduce vibration, structure-borne noise, and airborne noise inside vehicles. Often applied to floors, doors, trunks, and roof panels, these mats improve cabin acoustics, reduce road and engine noise, and enhance the perceived quality of a vehicle — a key selling point for fleets, aftermarket installers, and OEM suppliers.

Why B2B Buyers Should Prioritize Sound Deadening

Business benefits and ROI

Investing in car sound deadener mats delivers multiple commercial benefits: improved customer satisfaction, higher perceived build quality, fewer warranty claims related to rattles and vibrations, and opportunities for High Quality upsells (e.g., acoustic packages). For fleet operators and OEMs, even modest noise reduction of 2–6 dB in key frequency ranges can translate into measurable improvements in driver comfort and fatigue — driving better safety and productivity.

Common Types of Car Sound Deadener Mat

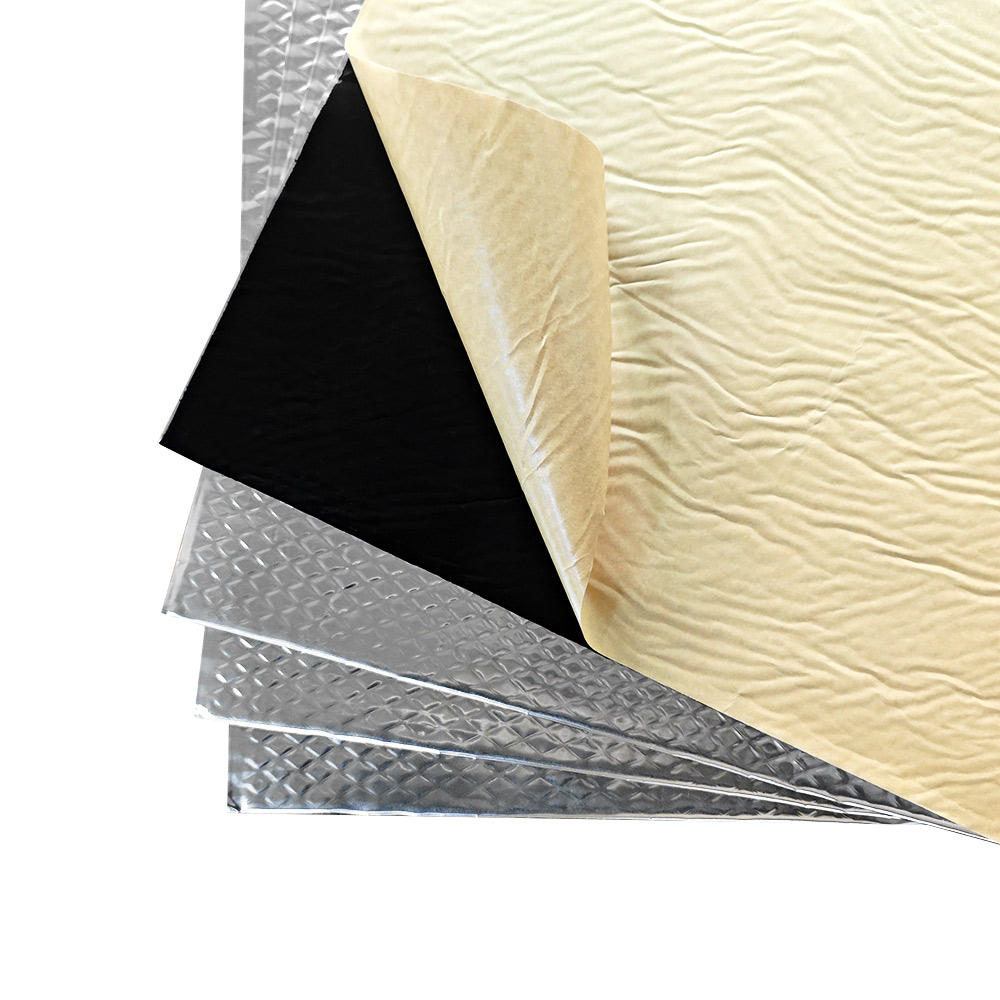

Butyl Rubber Sound Damping Mat — the market workhorse

Butyl rubber damping mats are widely used for automotive vibration damping. They combine a butyl-based viscoelastic layer with an aluminum or polymer facing for heat and moisture resistance. These mats excel at reducing panel vibration (mid-to-high frequencies) and are easy for installers to cut and apply, making them ideal for aftermarket fitters and assembly lines.

Mass Loaded Vinyl (MLV) — for airborne noise control

MLV is a dense, flexible membrane used to block airborne noise (low-to-mid frequencies). Because of its mass, MLV works well where sound insulation must prevent sound transmission through cavities, such as between firewall and passenger compartments or inside trunk linings. It’s commonly specified where both sound blocking and space constraints are factors.

Open-cell and closed-cell foams — support and absorption

Foam products such as NBR foam or polyurethane serve as acoustic absorbers and sealers. Closed-cell foams provide thermal insulation and moisture resistance, while open-cell foams absorb mid-to-high frequency noise inside door panels and headliners. These are complementary products to damping mats in a layered sound package.

Composite systems — layered solutions for best performance

High-performance car sound deadening systems often combine butyl damping mats, MLV barriers, and foams to target different noise paths and frequency ranges. Selecting the right composite depends on space, weight limits, cost targets, and targeted frequencies (engine, tire, wind, or infotainment fidelity).

Key Technical Specs B2B Buyers Need to Compare

Surface density and mass per unit area

Surface density (mass per unit area) is crucial for predicting how well a material blocks airborne noise. For barrier materials like MLV, density is a primary performance metric. Buyers should request datasheets with mass per square meter (kg/m2) or lb/ft2 values and confirm sample weight for accurate comparisons.

Loss factor and damping performance

Damping materials are graded by their loss factor or dynamic stiffness. A higher loss factor typically means better vibration energy dissipation. For vehicle panels, materials tuned to reduce resonant peaks in the 200–2000 Hz range are often most effective.

Thickness, conformability, and thermal limits

Thickness affects both performance and fit. Thin butyl mats (1.5–2.0 mm) are popular for doors and floors where space is tight; thicker variants (3–4 mm) provide stronger damping but need more clearance. Also check temperature performance and adhesive specifications — automotive applications require materials that withstand typical vehicle temperature ranges and adhesion under vibration.

Adhesive properties and long-term aging

Long-term bond integrity is a commercial risk factor. Choose products with pressure-sensitive adhesives formulated for automotive longevity and resistance to moisture, oil, and UV. Ask for accelerated aging test results and peel strength figures to validate lifetime performance.

Performance Metrics and Testing to Request

Acoustic test data you should require

Request standardized test reports: transmission loss (TL) curves, sound transmission class (STC) or similar metrics for barrier materials, and damping loss factor tests for viscoelastic layers. Real-world wheel-house or full-vehicle NVH (noise, vibration, harshness) test results are especially valuable for B2B procurement decisions.

Environmental and regulatory compliance

Confirm certifications and compliance: RoHS, REACH, low-VOC ratings, and any OEM-specific approvals. For international shipments, ensure materials meet regional environmental and flammability standards (e.g., FMVSS in the U.S. for certain applications, or supplier-specific fire-safety requirements).

Installation Considerations for Supply Contracts

Ease of installation and labor costs

Installation time directly affects total project cost. Self-adhesive butyl mats that can be cut and fitted quickly reduce labor hours. For large-scale programs, discuss pre-cut kits, automated application systems, or supplier-backed training programs to standardize fitment and minimize variability.

Surface prep, primers, and tooling

Proper surface preparation is mandatory: cleaning, degreasing, and sometimes primers improve adhesion, particularly in high-humidity or cold climates. Confirm if the supplier provides primers or compatible surface treatments and recommend tooling (rollers, heat guns) for efficient application.

Service life and maintenance

Ask suppliers for expected service life under typical automotive conditions and any recommended maintenance. Durable adhesives and UV-resistant facings help prevent peeling; closed-cell foams avoid moisture absorption that could degrade insulation performance over time.

Cost Considerations and Sourcing Strategies

Unit cost vs. system cost

Evaluate cost per square meter alongside installation labor, scrap, and warranty exposures. Often, upgrading to a slightly more expensive material with better adhesion or fewer installation steps reduces total cost of ownership through lower rework and longer useful life.

Volume discounts, lead times, and supply resilience

Negotiate volume-based pricing and lead times, and ask about production capacity and contingency plans. Suppliers with modern manufacturing bases, ISO certification, and multiple production lines can better support ramp-ups and minimize disruptions — critical for OEMs and large fleet projects.

Why Choose ASLONG as Your Sound Deadener Mat Partner?

Company strengths tailored for B2B procurement

ASLONG (Welllink Guangdong New Material Co., Ltd.) was founded in 2000 and is a high-tech enterprise specializing in R&D, production, and sales of acoustic and sound insulation materials. With a modern production base of over 10,000 m2, ASLONG supplies a wide range of products — Butyl Rubber Sound Damping Mat, Mass Loaded Vinyl, NBR foam, Sound White Cotton, Tire Silent Foam, Butyl Waterproof Tape, and electric auxiliary materials — to customers in Europe, North America, Asia, and Africa.

Global reach and OEM-ready capabilities

ASLONG exports internationally and supports OEMs, aftermarket distributors, and system integrators. The company offers material testing data, custom formulations, pre-cut kits, and technical support, making it easier for B2B buyers to integrate acoustic strategies into vehicle programs and retrofit projects.

Sustainability and compliance

ASLONG emphasizes environmentally friendly solutions and can provide compliance documentation for regional regulations. Buyers can request technical data sheets (TDS), material safety data sheets (MSDS), and performance test reports as part of procurement due diligence.

How to Evaluate Suppliers: A Practical Checklist

Procurement checklist for Car Sound Deadener Mat

Use this quick checklist when evaluating suppliers: 1) Request sample kits and fit them in representative panels; 2) Review acoustic test reports for target frequency ranges; 3) Verify adhesive performance and aging tests; 4) Confirm lead times, minimum order quantities, and logistics; 5) Ask for references from other OEMs or large installers; 6) Ensure environmental and flammability compliance; 7) Evaluate warranty and after-sales technical support.

Case Study Snapshot: Typical Fleet Upgrade Scenario

Problem, solution, and result (concise commercial example)

A commercial delivery fleet reported driver fatigue from road noise on long routes. The solution combined butyl damping mats on floor and doors, door cavity foams, and MLV in the bulkhead. After installation on a pilot group, subjective cabin noise ratings improved and drivers reported increased comfort. On a per-vehicle basis, the system cost was offset by driver retention and better customer perception of vehicle quality.

Packaging, Logistics, and Worldwide Distribution

How packaging and logistics affect procurement

For international buyers, packaging density, palletization, and customs documentation affect landed cost. ASLONG’s experience exporting to multiple continents helps optimize packaging for reduced freight costs and damage prevention. Discuss bonded warehouse options and drop-shipping for aftermarket distribution.

Conclusion: How to Move Forward as a B2B Buyer

Next steps to secure the right sound deadener mat

Start with a clear specification: target frequencies, available space, weight limits, environmental constraints, and cost targets. Request sample kits and test them in representative vehicle panels. Compare suppliers using the checklist above, and favor partners who provide technical support, compliance documentation, and flexible production capacity. For reliable acoustic materials and global supply capabilities, consider engaging with ASLONG to explore tailored solutions and volume pricing.

Contact and Supplier Engagement

How to contact ASLONG for B2B procurement

If you’re procuring at scale or seeking distribution partnerships, ASLONG is recruiting agents worldwide and offers OEM and aftermarket support. Request a quotation, technical datasheets, and sample kits to evaluate product performance in your application. A well-documented trial and clear installation SOP will accelerate supplier qualification.

Contact ASLONG’s commercial team to request samples, TDS, and pilot program pricing tailored to your fleet or production volume.

Frequently Asked Questions:

What is the main difference between butyl sound deadener and mass loaded vinyl?Butyl damping mats primarily reduce panel vibration (structure-borne noise) while mass loaded vinyl acts as a dense barrier to block airborne noise. Many high-performance solutions use both in layers.

How much noise reduction can I reasonably expect from adding sound deadener mats?Typical, well-engineered installations yield measurable reductions in cabin noise in the range of 2–6 dB for general road noise, with greater subjective improvements in perceived quality. Exact results vary with vehicle type, coverage area, and materials used.

Are these materials safe and environmentally compliant?Reputable suppliers provide RoHS/REACH compliance, low-VOC formulations, and MSDS documents. Ask your supplier for full compliance documentation and third-party test reports for verification.

What installation time and labor should I budget for in a retrofit program?Installation time depends on coverage and complexity — a partial door-and-floor retrofit may take a few hours per vehicle by an experienced technician, while full-vehicle installations require more labor. For large programs, negotiate pre-cut kits and training to reduce per-unit labor.

Can ASLONG supply materials at OEM volumes and provide customization?Yes. ASLONG has been producing acoustic and insulation materials since 2000, offers a range of products (butyl mats, MLV, NBR foams, etc.), and supports custom formulations, pre-cut kits, and global distribution. Contact ASLONG’s sales team for volume pricing and technical collaboration.

How to start the rubber tape manufacturing business ?

Tips for buy self-adhesive automotive sound deadening mat

Automotive Sound Deadening Material Safety and Durability 2026

What is polyester electrical tape

FAQs

How to customize products that meet the needs of my industry?

You only need to contact our sales or technical team, we will conduct an in-depth analysis based on your industry needs and provide tailor-made products and solutions. We guarantee to provide you with efficient and accurate services to meet your personalized requirements.

Does ASLONG provide after-sales service?

Yes, we provide a full range of after-sales services, including technical support, installation guidance, product maintenance and quality tracking, etc., to ensure that each project goes smoothly and continues to perform at its best.

What industries are the products provided by ASLONG suitable for?

ASLONG's products are suitable for multiple industries, including air conditioning and HVAC, construction and waterproofing, automobiles and transportation, home appliances and electronics, industrial equipment and machinery, etc. We provide customized solutions for each industry to meet different needs.

What specific functions can ASLONG's products provide?

Our products cover functions such as insulation, sound insulation, shock absorption, waterproofing and sealing, and are widely used in improving energy efficiency, reducing noise, controlling vibration, protecting equipment, etc., helping customers optimize engineering effects and improve user experience.

Do ASLONG's products meet environmental protection standards?

Yes, all ASLONG products comply with ISO14001 environmental management system certification and global environmental protection standards. We use environmentally friendly materials and are committed to providing sustainable solutions to help customers achieve green development goals.

Car sound deadener mat

Butyl Rubber Sound Damping Mat

ASLONG Butyl Rubber Sound Damping Mat for sale. Effectively reduces noise and vibrations. High-quality butyl rubber ensures superior performance and durability. Ideal for automotive, industrial, and home applications.

Mass Loaded Vinyl

ASLONG Mass Loaded Vinyl for sale. Reduce noise pollution effectively with our high-quality, mass-loaded vinyl. Ideal for soundproofing walls, floors, and more. Buy now and experience the difference!

Egg Crate Foam

ASLONG Egg Crate Foam for sale. Lightweight, breathable, and comfortable, our egg crate foam provides superior support and pressure relief. Perfect for mattresses, cushions, cars, construction industry, KTV, factories, etc.

Professional support at any time

If you have any comments or good suggestions, please leave us a message; later our professional staff will contact you as soon as possible.

© 2026 ASLONG All Rights Reserved. Privacy Policy | Terms and Conditions | Sitemap

Whatsapp: +8613242879341

ASLONG Global

ASLONG

Aslong_global