Customization & OEM Packaging for Butyl Rubber Sound Damping Mat

- Customization & OEM Packaging for Butyl Rubber Sound Damping Mat

- Product introduction — Butyl Rubber Sound Damping Mat

- Why choose a butyl rubber sheet for sound damping?

- Key performance characteristics of Butyl Rubber Sound Damping Mat

- How these characteristics support OEM requirements

- Applications: automotive, industrial, and home uses for Butyl Rubber Sound Damping Mat

- Customization options for Butyl Rubber Sound Damping Mat

- OEM packaging solutions for Butyl Rubber Sound Damping Mat

- Technical considerations for custom sizing, adhesive choice, and installation

- Installation best practices for maximum sound damping

- Testing, standards, and quality metrics for Butyl Rubber Sound Damping Mat

- Comparing Butyl Rubber Sound Damping Mat with other common damping materials

- ASLONG brand advantages and OEM support for Butyl Rubber Sound Damping Mat

- Cost considerations and lead times for custom and OEM orders

- Frequently Asked Questions (FAQ)

- Q: What is the primary advantage of using a butyl rubber sheet vs. bitumen?

- Q: Can ASLONG provide custom die-cut Butyl Rubber Sound Damping Mat to match OEM part numbers?

- Q: Are there adhesive options suitable for painted surfaces and paint-bake cycles?

- Q: What packaging options are available for retail and OEM customers?

- Q: How should I store butyl rubber mats before use?

- Contact & product access (CTA)

- Authoritative resources and references

Customization & OEM Packaging for Butyl Rubber Sound Damping Mat

Product introduction — Butyl Rubber Sound Damping Mat

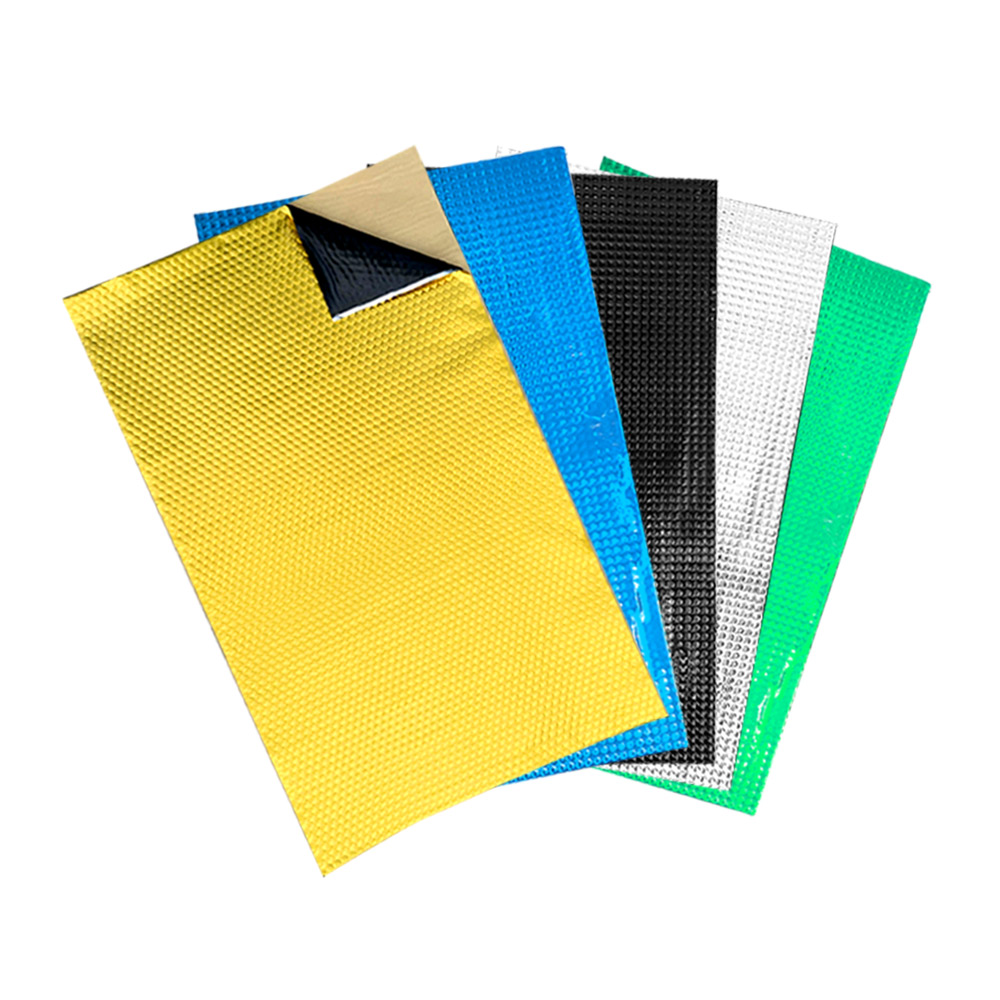

ASLONG Butyl Rubber Sound Damping Mat for sale. Effectively reduces noise and vibrations. High-quality butyl rubber ensures superior performance and durability. Ideal for automotive, industrial, and home applications.

Why choose a butyl rubber sheet for sound damping?

Butyl rubber sheet is widely used for sound damping because of its high internal damping, excellent adhesion characteristics, and long-term dimensional stability. For manufacturers and specifiers evaluating materials, a butyl rubber sound damping mat delivers effective structure-borne noise reduction across a broad frequency range, resisting creep and degradation from temperature cycles better than many alternatives. This makes butyl an ideal base material for OEM parts and aftermarket soundproofing kits where predictable, durable performance is required.

Key performance characteristics of Butyl Rubber Sound Damping Mat

When selecting a butyl rubber sound damping mat, consider these measurable characteristics that directly affect acoustical performance and installation reliability:

- Loss factor (damping coefficient): High loss factor improves energy dissipation for vibrations.

- Adhesion strength: Strong peel adhesion to metal and composite substrates reduces delamination.

- Operating temperature range: Butyl typically withstands -40°C to 120°C depending on formulation.

- Thickness & mass: Higher mass per area increases low-frequency attenuation; thickness choice balances flexibility and fit.

- Durability and aging: UV and chemical resistance influence long-term effectiveness, especially in exposed applications.

How these characteristics support OEM requirements

For OEMs, consistency in sheet thickness, adhesive coating, and die-cut tolerances are essential. ASLONG’s manufacturing controls for butyl rubber sheet ensure repeatable loss factor and adhesion metrics so that assembly-line fit and vehicle NVH (Noise, Vibration, Harshness) targets remain stable across production batches.

Applications: automotive, industrial, and home uses for Butyl Rubber Sound Damping Mat

The Butyl Rubber Sound Damping Mat is multi-purpose. Common application areas include:

- Automotive: doors, floor pans, trunks, roof liners, wheel arches — reduces road and engine noise, and prevents resonance panels.

- Industrial: machinery housings, HVAC units, pump mounts — reduces equipment-borne vibrations and improves worker comfort.

- Home & building: appliance enclosures, HVAC ducts, wall cavity damping — improves perceived build quality and reduces sound transmission.

Each application drives different customization priorities: automotive OEMs emphasize die-cut precision and automotive-grade adhesives; industrial buyers may prioritize high-temperature formulations; home-improvement channels often require consumer-friendly roll sizes and easy-trim features.

Customization options for Butyl Rubber Sound Damping Mat

Manufacturers and buyers commonly request customization to meet form, function, and brand requirements. Available customization options include:

- Thickness and mass per unit area — from light-weight 1–2 mm sheets for small panels to thicker 3–5 mm mats for trunk and floor applications.

- Die-cut shapes — precision cut to complex part geometries for direct-fit OEM replacement parts.

- Adhesive formulation — standard pressure-sensitive adhesive or high-temp adhesives for paint-bake cycles.

- Surface finish — foil-faced for heat reflectivity, cloth-faced for appearance, or plain butyl for maximum stick and conformability.

- Perforations and scoring — to allow contouring around ribs and fastener bosses.

- Color and branding — custom colors and printed logos for aftermarket retail or OEM private-label packs.

Choosing the right combination depends on end-use: for example, a butyl rubber sheet intended for engine bay firewall use should use high-temperature adhesive and possibly a foil face, while interior door liners need thin, low-profile mats with strong initial tack.

OEM packaging solutions for Butyl Rubber Sound Damping Mat

OEMs and large distributors require packaging that preserves product integrity, eases assembly-line handling, and optimizes logistics. Typical OEM packaging and fulfillment options include:

- Bulk rolls with protective interleaving and clear labeling for batch traceability.

- Pre-cut, stackable kits in labeled cartons for just-in-time line feeding.

- Blister or clamshell packaging for retail-ready parts where consumer presentation matters.

- Custom kit assembly — inclusion of installation tools, primers, and instructions to reduce line-side assembly time or improve DIY success rates.

- Barcoding and serialized labels for quality control and recall-readiness.

Packaging design should balance protection (against dust, moisture, and compression) and ergonomics (easy peel, simple orientation) to reduce waste and handling time on the production floor.

Technical considerations for custom sizing, adhesive choice, and installation

When specifying a butyl rubber sheet for customized parts, consider these technical checkpoints:

- Substrate compatibility: ensure the adhesive adheres to paint, bare metal, composites, or plastics as required; surface primers may be recommended.

- Temperature exposure: choose adhesive and butyl formulation compatible with the component’s maximum service temperature.

- Curing or paint-bake requirements: confirm the mat tolerates assembly-line thermal cycles if applied pre-paint or before final curing steps.

- Fastener and compression points: design cutouts or thinner zones to allow bolts and clips to seat properly without extruding material.

- Storage and shelf life: butyl sheet should be stored away from direct sunlight and extreme temperatures; manufacturer-specified shelf life must be followed to retain adhesive performance.

Installation best practices for maximum sound damping

Correct installation is critical to realize the acoustic benefits of a Butyl Rubber Sound Damping Mat. Follow these best practices:

- Surface preparation: degrease and dry; use an alcohol wipe or recommended primer for painted surfaces to improve adhesion.

- Apply pressure: a roller or hand press ensures full contact and removes air pockets that reduce damping efficiency.

- Overlap and edge sealing: avoid gaps; slightly overlap seams or use seam tape to prevent flapping under vibration.

- Avoid over-stretching: butyl is flexible but excessive stretching during application can thin the material and reduce mass per area.

- Allow dwell time: give adhesive time to develop high bond strength if recommended by the manufacturer before subjecting to load cycles.

Testing, standards, and quality metrics for Butyl Rubber Sound Damping Mat

Reputable suppliers provide testing data to support acoustic claims. Key tests and standards include:

- Damping/loss factor measurement (dynamic mechanical analysis — DMA).

- ISO/ASTM standards for material characterization and adhesive performance (e.g., peel strength tests).

- Automotive NVH validation: vehicle-level sound reduction testing and transfer path analysis.

Manufacturers typically provide test reports or material data sheets that include density, tensile properties, temperature ranges, and adhesion metrics so engineers can integrate the butyl rubber sheet into specifications confidently.

Comparing Butyl Rubber Sound Damping Mat with other common damping materials

Below is a concise comparison to help select the right material:

| Material | Damping Performance | Temperature Range | Adhesion | Durability | Ideal Uses |

|---|---|---|---|---|---|

| Butyl rubber sheet | High (broadband) | -40°C to 120°C (typical) | Excellent (PSA options) | High (low creep) | Automotive panels, industrial housings, OEM kits |

| Bitumen mats | Good (low-frequency) | -10°C to 80°C | Moderate | Moderate (can flow at high temps) | Heavy low-freq damping in non-high-temp areas |

| Foam / open-cell | Good (airborne absorption) | -40°C to 80°C | N/A (usually non-adhesive) | Moderate | Acoustic absorption inside enclosures, HVAC |

ASLONG brand advantages and OEM support for Butyl Rubber Sound Damping Mat

ASLONG’s product line of Butyl Rubber Sound Damping Mat emphasizes quality control, customizable manufacturing, and OEM-ready packaging. Key brand advantages include:

- Consistent material properties: batch-controlled formulations ensure repeatable damping performance for production runs.

- Custom die-cut and roll-to-roll capabilities: supports high-volume OEM orders and precise aftermarket kits.

- Adhesive options: automotive-grade adhesives that withstand paint-bake cycles and long-term environmental exposure.

- Packaging flexibility: bespoke packaging, labeling, and kit assembly services to match production or retail needs.

- Technical support: engineering guidance on material selection, part design, and installation best practices to meet NVH targets.

For OEMs and distributors, ASLONG combines product performance with logistical and technical services to reduce integration risk and accelerate time-to-line.

Cost considerations and lead times for custom and OEM orders

Customization and OEM packaging introduce additional per-order costs and lead times compared with standard stocked items. Typical cost drivers include tooling for die-cut parts, minimum order quantities for custom adhesive or surface finishes, and labor for kit assembly. Lead times vary by scope—simple die-cuts can be fulfilled in weeks, whereas bespoke adhesive formulations and retail packaging may require longer qualification lead times (6–12 weeks). ASLONG works with customers to balance MOQ, unit cost, and timeline to meet project constraints.

Frequently Asked Questions (FAQ)

Q: What is the primary advantage of using a butyl rubber sheet vs. bitumen?

A: Butyl rubber sheets offer better high-temperature stability, less creep, and superior adhesion options. They also provide broadband damping suitable for many NVH problems, whereas bitumen often targets low-frequency damping but can soften or flow at higher temperatures.

Q: Can ASLONG provide custom die-cut Butyl Rubber Sound Damping Mat to match OEM part numbers?

A: Yes. ASLONG offers precision die-cutting with tight tolerances and labeling to match OEM part numbers and assembly-line requirements. We support CAD-to-tool workflows and sample approvals prior to mass production.

Q: Are there adhesive options suitable for painted surfaces and paint-bake cycles?

A: Yes. ASLONG supplies pressure-sensitive adhesives and high-temperature adhesive formulations that withstand paint-bake cycles and retain bond strength on painted or primer-coated substrates.

Q: What packaging options are available for retail and OEM customers?

A: Options include bulk rolls, pre-cut kits in labeled cartons, blister packs for retail, and custom-assembled kits with installation accessories and printed instructions.

Q: How should I store butyl rubber mats before use?

A: Store in a cool, dry place away from direct sunlight. Follow manufacturer shelf-life guidance—typically up to 12 months when stored properly. Avoid folding or compressing rolls for extended periods to prevent adhesive migration.

Contact & product access (CTA)

If you need custom sizing, OEM packaging, or technical evaluation samples of the Butyl Rubber Sound Damping Mat, contact ASLONG sales today. For product specifications, quotation, or to request die-cut samples and packaging mockups, reach out to our sales team or visit the product page to place an order and get engineering support.

Authoritative resources and references

For further technical grounding and standards information referenced consult the following authoritative sources:

- Butyl rubber — Wikipedia: https://en.wikipedia.org/wiki/Butyl_rubber

- Soundproofing (acoustics) — Wikipedia: https://en.wikipedia.org/wiki/Soundproofing

- ISO and ASTM standards catalog (general reference): https://www.iso.org and https://www.astm.org

- SAE International (automotive NVH resources): https://www.sae.org

Top 5 mass loaded vinyl sheet Company List and Products Compared

How to manufacturing Car Sound Deadening Foam

How to start the cable accessories business ?

How to manufacturing waterproof butyl tape

FAQs

How to customize products that meet the needs of my industry?

You only need to contact our sales or technical team, we will conduct an in-depth analysis based on your industry needs and provide tailor-made products and solutions. We guarantee to provide you with efficient and accurate services to meet your personalized requirements.

What industries are the products provided by ASLONG suitable for?

ASLONG's products are suitable for multiple industries, including air conditioning and HVAC, construction and waterproofing, automobiles and transportation, home appliances and electronics, industrial equipment and machinery, etc. We provide customized solutions for each industry to meet different needs.

Does ASLONG provide after-sales service?

Yes, we provide a full range of after-sales services, including technical support, installation guidance, product maintenance and quality tracking, etc., to ensure that each project goes smoothly and continues to perform at its best.

What specific functions can ASLONG's products provide?

Our products cover functions such as insulation, sound insulation, shock absorption, waterproofing and sealing, and are widely used in improving energy efficiency, reducing noise, controlling vibration, protecting equipment, etc., helping customers optimize engineering effects and improve user experience.

Do ASLONG's products meet environmental protection standards?

Yes, all ASLONG products comply with ISO14001 environmental management system certification and global environmental protection standards. We use environmentally friendly materials and are committed to providing sustainable solutions to help customers achieve green development goals.

Butyl Rubber Sound Damping Mat

ASLONG Butyl Rubber Sound Damping Mat for sale. Effectively reduces noise and vibrations. High-quality butyl rubber ensures superior performance and durability. Ideal for automotive, industrial, and home applications.

Mass Loaded Vinyl

ASLONG Mass Loaded Vinyl for sale. Reduce noise pollution effectively with our high-quality, mass-loaded vinyl. Ideal for soundproofing walls, floors, and more. Buy now and experience the difference!

Egg Crate Foam

ASLONG Egg Crate Foam for sale. Lightweight, breathable, and comfortable, our egg crate foam provides superior support and pressure relief. Perfect for mattresses, cushions, cars, construction industry, KTV, factories, etc.

NBR Foam

ASLONG NBR Foam: Wholesale NBR foam solutions for diverse applications. High-quality, durable, and competitively priced. Contact us today for bulk orders.

Professional support at any time

If you have any comments or good suggestions, please leave us a message; later our professional staff will contact you as soon as possible.

© 2026 ASLONG All Rights Reserved. Privacy Policy | Terms and Conditions | Sitemap

Whatsapp: +8613242879341

ASLONG Global

ASLONG

Aslong_global