How Suppliers Certify Butyl Rubber Sound Damping Mat Quality

- How Suppliers Certify Butyl Rubber Sound Damping Mat Quality

- Why Certification Matters for Butyl Rubber Sheet Quality

- : choosing certified damping mats

- Key Properties Suppliers Test in Butyl Rubber Sound Damping Mat

- Standards and Test Methods Suppliers Rely On

- Typical Laboratory Tests — What They Show

- In-House Testing vs Third-Party Laboratory Certification

- In-house testing

- Third-party laboratory testing

- Quality Management, Traceability and Batch Control

- What traceability should buyers request?

- Factory Audits and Supplier Qualification Steps

- Common Pitfalls and How Buyers Can Protect Themselves

- How ASLONG Demonstrates Certification and Quality for Butyl Rubber Sound Damping Mat

- Practical Checklist: What to Request from a Supplier

- Cost vs. Value: Why Certified Butyl Rubber Sheet Is Worth It

- FAQ — Common Questions About Certification and Butyl Rubber Sound Damping Mat

- Q: What does a typical test report for a Butyl Rubber Sound Damping Mat include?

- Q: Is ISO/IEC 17025 essential for acoustic test labs?

- Q: How often should suppliers retest their production?

- Q: Can in-house tests replace third-party certification?

- Q: What are common red flags when evaluating supplier documents?

- Contact & View Product

- Authoritative References

How Suppliers Certify Butyl Rubber Sound Damping Mat Quality

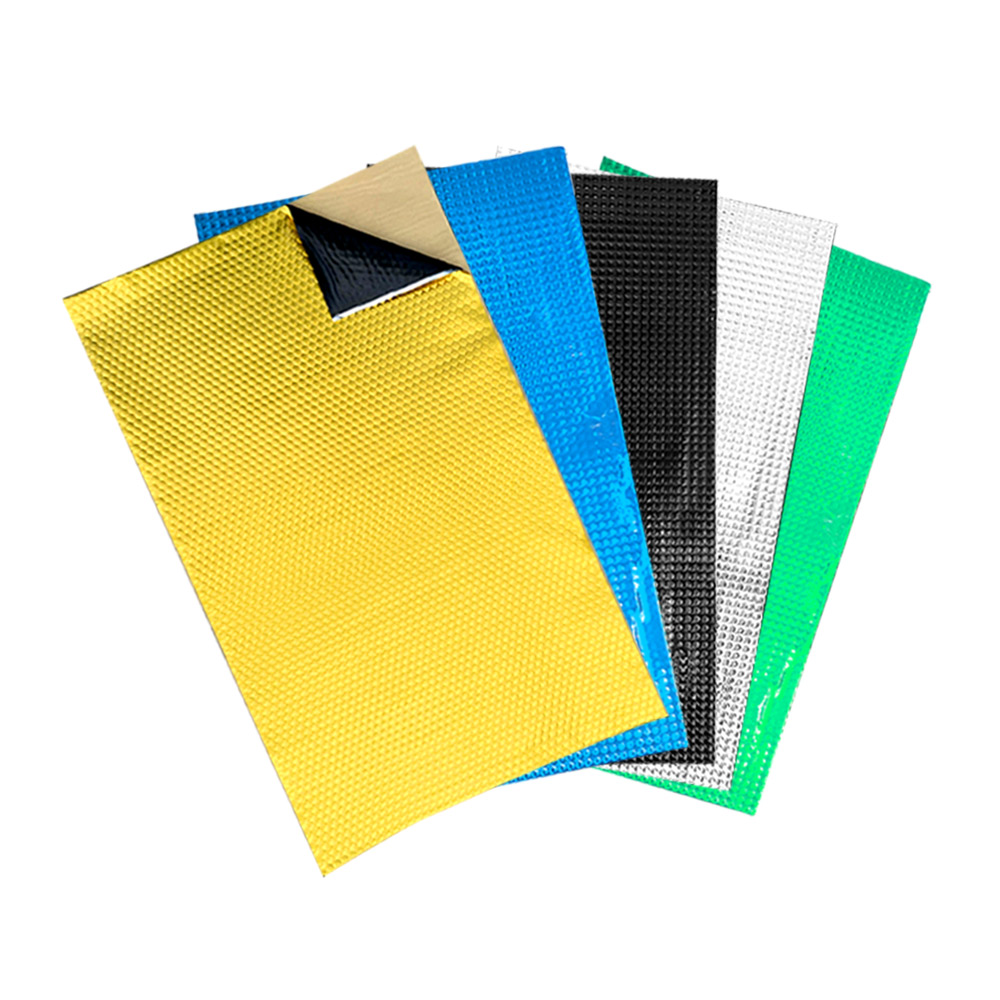

ASLONG Butyl Rubber Sound Damping Mat for sale. Effectively reduces noise and vibrations. High-quality butyl rubber ensures superior performance and durability. Ideal for automotive, industrial, and home applications.

Why Certification Matters for Butyl Rubber Sheet Quality

Buyers choose a butyl rubber sheet or Butyl Rubber Sound Damping Mat for its noise reduction, durability, and ease of installation. Certification proves the product meets performance and safety expectations: consistent acoustic damping, durability under temperature cycling, adhesion, environmental compliance (RoHS/REACH), and low emissions. Without certification, a supplier’s claims are difficult to verify, increasing risk of premature failure, warranty claims, or regulatory issues.

: choosing certified damping mats

For fleet purchasers, OEMs, or installers, certified materials reduce procurement risk and simplify compliance checks. Certifications and test reports support tender responses and quality audits, making certified Butyl Rubber Sound Damping Mat a preferred commercial choice.

Key Properties Suppliers Test in Butyl Rubber Sound Damping Mat

Suppliers evaluate a set of physical, mechanical, acoustic, and environmental properties. Typical properties tested include:

- Mass per unit area (g/m²) — affects damping performance and added weight.

- Dynamic stiffness and loss factor — direct indicators of vibration damping effectiveness.

- Sound transmission loss and insertion loss — how the mat reduces airborne and structure-borne noise.

- Tensile strength, elongation, and tear resistance — mechanical durability during handling and installation.

- Adhesion (peel strength) — ensures mat stays in place on metal or substrate.

- Thermal aging and low/high temperature performance — ensures long-term function across temperature ranges.

- Flammability and smoke generation — relevant for safety in vehicles and buildings.

- Volatile Organic Compounds (VOCs) and chemical compliance (RoHS, REACH) — indoor air quality and regulatory compliance.

Standards and Test Methods Suppliers Rely On

Suppliers reference international standards to produce objectively comparable results. Common standards used for butyl rubber sheets and damping mats include:

- ISO/IEC 17025 — laboratory accreditation standard ensuring testing competence.

- ASTM standards for rubber testing (e.g., tensile, tear, aging) — widely used for material properties.

- ISO 10140 series or ASTM E90 — laboratory measurement of sound insulation and transmission loss.

- Industry-specific standards such as automotive OEM test protocols and SAE methods for NVH (Noise, Vibration, Harshness) performance.

- RoHS and REACH for chemical compliance and restricted substance lists.

Using recognized standards allows suppliers to produce test reports that engineers and procurement teams accept without re-testing every lot.

Typical Laboratory Tests — What They Show

Below is a concise table comparing common test types, what they measure, and typical standard references.

| Test | Purpose | Common Standard / Method |

|---|---|---|

| Mass per unit area | Verifies mat weight consistency and expected damping | Company spec / ISO mass measurements |

| Dynamic stiffness / Loss factor | Quantifies vibration damping capacity | ISO mechanical damping methods / DMA |

| Sound transmission / Insertion loss | Measures airborne and structure-borne noise reduction | ISO 10140 series, ASTM E90 |

| Tensile, elongation, tear | Determines mechanical durability and handling robustness | ASTM D412 (tensile), ASTM D624 (tear) |

| Adhesion / Peel strength | Checks self-adhesive backing performance | Company test method / ASTM D1000 variant |

| Thermal aging | Assesses property retention after heat exposure | ASTM thermal aging methods |

| VOCs / Emissions | Evaluates indoor air quality impact | ISO, EN, or local VOC test methods |

In-House Testing vs Third-Party Laboratory Certification

Suppliers operate along a spectrum: some rely on in-house controlled testing, others use independent accredited laboratories. Each approach has strengths.

In-house testing

Pros: fast feedback, routine production control, reduced costs. Cons: potential perceived bias; results may be less credible for high-stakes buyers unless the lab is accredited to ISO/IEC 17025 and publishes traceable methods.

Third-party laboratory testing

Pros: independent verification, higher buyer confidence, acceptance in international tenders. Cons: longer lead times and additional costs. Most reputable suppliers provide third-party test reports for new product lines and periodic batch verification.

Quality Management, Traceability and Batch Control

Certification is not a one-off test. Reliable suppliers implement quality management systems (often ISO 9001) with documented procedures covering raw material acceptance, production monitoring, batch numbering, and retained sample programs. Traceability allows a specific roll or sheet to be linked back to raw material lots and test results.

What traceability should buyers request?

- Batch or roll number linked to test reports.

- Date of production and shelf-life guidance.

- Raw material certificates (e.g., polymer supplier declarations).

- Material Safety Data Sheet (MSDS) / SDS and compliance certificates (RoHS/REACH where applicable).

Factory Audits and Supplier Qualification Steps

Beyond paperwork, buyers often require supplier qualification steps. A common process includes:

- Requesting technical datasheets and third-party test reports for the Butyl Rubber Sound Damping Mat.

- Reviewing the supplier’s ISO/IEC 17025 and ISO 9001 certificates and lab accreditation records.

- Sampling and independent lab verification (witnessed or blind tests).

- Factory visit or third-party audit to inspect production controls and test equipment.

- Pilot order and in-field performance evaluation (especially for automotive NVH applications).

Common Pitfalls and How Buyers Can Protect Themselves

Even with certification, issues can arise. Here’s how to reduce risk:

- Verify lab accreditation (ISO/IEC 17025) directly with the issuing body or on the lab’s certificate.

- Ask for raw data or full test reports rather than summary certificates; check testing conditions, sample prep, and frequency.

- Insist on batch-level traceability and retained samples for dispute resolution.

- Use independent verification testing for critical applications or large volumes.

- Include clear acceptance criteria in purchase orders (e.g., mass tolerance, adhesion minimums, VOC limits).

How ASLONG Demonstrates Certification and Quality for Butyl Rubber Sound Damping Mat

When evaluating suppliers, ASLONG positions its Butyl Rubber Sound Damping Mat as a certified, high-performance product. Key brand strengths and proof points include:

- Comprehensive test documentation for dynamic stiffness, insertion loss, tensile properties, and adhesion.

- Third-party acoustic performance reports conducted in accredited facilities.

- Material compliance documentation (RoHS/REACH) and detailed SDS/MSDS files for safe handling.

- Production traceability with batch numbers and retained sample programs.

- Quality management systems that align with ISO 9001 and periodic factory audits.

These elements reduce procurement risk and help customers — from automotive OEMs to aftermarket installers — specify ASLONG Butyl Rubber Sound Damping Mat with confidence.

Practical Checklist: What to Request from a Supplier

Before purchase, request the following to verify claims and protect your project:

- Full test reports (not only pass/fail) showing test conditions and dates.

- Lab accreditation certificate for independent labs (ISO/IEC 17025).

- Sample rolls and installation guidance for real-world trials.

- MSDS/SDS and chemical compliance documents (RoHS/REACH).

- Batch numbering, production date, and shelf-life recommendations.

- Warranty terms and failure analysis procedures.

Cost vs. Value: Why Certified Butyl Rubber Sheet Is Worth It

Certified materials often carry a higher unit cost, but the total cost of ownership is lower for critical applications. Benefits include fewer returns, reduced rework, shortened qualification cycles, and lower warranty exposure. For automotive and industrial users, these savings typically offset the High Quality paid for certified Butyl Rubber Sound Damping Mat.

FAQ — Common Questions About Certification and Butyl Rubber Sound Damping Mat

Q: What does a typical test report for a Butyl Rubber Sound Damping Mat include?

A: It normally includes sample identification, test dates, test methods and standards, raw data (e.g., insertion loss vs frequency), measured properties (mass per area, dynamic stiffness, tensile, adhesion), environmental conditioning details, and the testing laboratory’s accreditation information.

Q: Is ISO/IEC 17025 essential for acoustic test labs?

A: While not legally required in all regions, ISO/IEC 17025 accreditation demonstrates a lab’s competence and reliability. For critical specifications and international procurement, it’s strongly recommended.

Q: How often should suppliers retest their production?

A: Frequency depends on product criticality and customer agreements. Typical practices include batch-level verification for adhesion and mass, quarterly or biannual acoustic checks, and annual full-property audits. High-volume or mission-critical programs often require more stringent schedules.

Q: Can in-house tests replace third-party certification?

A: In-house tests are vital for daily quality control, but third-party testing adds independent validation and higher buyer confidence. A combination of both is best practice.

Q: What are common red flags when evaluating supplier documents?

A: Red flags include missing test conditions, no lab accreditation, summary-only reports without raw data, inconsistent batch identifiers, and lack of traceability to raw materials.

Contact & View Product

If you would like to evaluate ASLONG Butyl Rubber Sound Damping Mat or request technical documentation and test reports, contact our sales team or view product details on our site. We provide sample rolls, full test reports, and support for specification and installation.

Authoritative References

Below are authoritative resources referenced in this article for standards, testing, and material information:

- Butyl rubber — Wikipedia: https://en.wikipedia.org/wiki/Butyl_rubber

- ISO/IEC 17025 — General requirements for the competence of testing and calibration laboratories: https://www.iso.org/standard/66912.

- ISO 10140 — Laboratory measurement of sound insulation: https://www.iso.org/standard/49736.

- ASTM International — Standards for materials and testing: https://www.astm.org/

- RoHS (EU restriction of hazardous substances): https://ec.europa.eu/environment/waste/rohs_eee/index_en.htm

- REACH (European Chemicals Agency): https://echa.europa.eu/

- ISO 9001 — Quality management systems: https://www.iso.org/iso-9001-quality-management.

For purchase inquiries, sample requests, or to receive ASLONG’s complete test dossier for Butyl Rubber Sound Damping Mat, please contact our sales team or visit our product page.

Top 10 sound deadening insulation for cars Manufacturers and Supplier Brands

ASLONG Best professional acoustic material manufacturers and supplier brands

Wholesale conductive foam adhesive tape manufacturer and supplier

Technical Spec Checklist for Multi layer Composite NBR Foam Purchases

FAQs

Does ASLONG provide after-sales service?

Yes, we provide a full range of after-sales services, including technical support, installation guidance, product maintenance and quality tracking, etc., to ensure that each project goes smoothly and continues to perform at its best.

How to customize products that meet the needs of my industry?

You only need to contact our sales or technical team, we will conduct an in-depth analysis based on your industry needs and provide tailor-made products and solutions. We guarantee to provide you with efficient and accurate services to meet your personalized requirements.

Do ASLONG's products meet environmental protection standards?

Yes, all ASLONG products comply with ISO14001 environmental management system certification and global environmental protection standards. We use environmentally friendly materials and are committed to providing sustainable solutions to help customers achieve green development goals.

What specific functions can ASLONG's products provide?

Our products cover functions such as insulation, sound insulation, shock absorption, waterproofing and sealing, and are widely used in improving energy efficiency, reducing noise, controlling vibration, protecting equipment, etc., helping customers optimize engineering effects and improve user experience.

What industries are the products provided by ASLONG suitable for?

ASLONG's products are suitable for multiple industries, including air conditioning and HVAC, construction and waterproofing, automobiles and transportation, home appliances and electronics, industrial equipment and machinery, etc. We provide customized solutions for each industry to meet different needs.

Butyl Rubber Sound Damping Mat

ASLONG Butyl Rubber Sound Damping Mat for sale. Effectively reduces noise and vibrations. High-quality butyl rubber ensures superior performance and durability. Ideal for automotive, industrial, and home applications.

Mass Loaded Vinyl

ASLONG Mass Loaded Vinyl for sale. Reduce noise pollution effectively with our high-quality, mass-loaded vinyl. Ideal for soundproofing walls, floors, and more. Buy now and experience the difference!

Egg Crate Foam

ASLONG Egg Crate Foam for sale. Lightweight, breathable, and comfortable, our egg crate foam provides superior support and pressure relief. Perfect for mattresses, cushions, cars, construction industry, KTV, factories, etc.

NBR Foam

ASLONG NBR Foam: Wholesale NBR foam solutions for diverse applications. High-quality, durable, and competitively priced. Contact us today for bulk orders.

Professional support at any time

If you have any comments or good suggestions, please leave us a message; later our professional staff will contact you as soon as possible.

© 2026 ASLONG All Rights Reserved. Privacy Policy | Terms and Conditions | Sitemap

Whatsapp: +8613242879341

ASLONG Global

ASLONG

Aslong_global