Acoustic Performance Tests Buyers Should Request for Rubber Mats

- Why specific acoustic tests matter for rubber mats

- Airborne versus structure-borne noise: two different challenges

- Material properties that determine acoustic behavior

- Installation and substrate effects

- Key acoustic tests buyers should request

- Transmission Loss and Sound Transmission Class (STC)

- Impact Insulation Class (IIC) and structure-borne tests

- Insertion loss and noise reduction coefficients (NRC)

- Mechanical and durability tests that affect long-term noise control

- Dynamic stiffness and loss factor measurements

- Environmental aging: temperature cycling, humidity, and UV

- Adhesion, compression set, and fatigue tests

- How to interpret test reports and specify acceptance criteria

- Reading frequency-dependent charts

- Typical acceptance thresholds by application

- Example comparison table: tests, purpose, standards, and why you should request them

- Making practical procurement decisions and test specification language

- Request test reports, not claims

- Specify assembly-level tests when possible

- Balance cost, weight and acoustic gains

- References and standards (authoritative sources)

- Product highlight: Butyl Rubber Sound Damping Mat

- Frequently Asked Questions (FAQ)

- Q: Which single test should I insist on first?

- Q: Are STC and IIC enough to compare mats?

- Q: How do I evaluate long-term performance?

- Q: Should tests be performed by third-party labs?

- Q: What if my installation substrate differs from the lab test?

Purchasing rubber mats for sound control requires more than just comparing thickness and price. To ensure consistent noise reduction and long-term performance, buyers should request specific acoustic, mechanical and environmental tests—laboratory and in-situ—that quantify how a material performs across frequencies, under load, and after aging. This article explains the critical tests to request for rubber mats (including butyl-based sound damping mats), how to interpret results, and what acceptance criteria to specify so the selected solution meets your application needs.

Why specific acoustic tests matter for rubber mats

Airborne versus structure-borne noise: two different challenges

Rubber mats and butyl sound damping products address both airborne noise (sound traveling through air) and structure-borne noise (vibrations transmitted through solids). Tests for airborne insulation (e.g., transmission loss) differ from tests for impact or structure-borne transmission (e.g., IIC or insertion loss). A high-performing damping mat may reduce vibration-induced tonal noise but offer limited airborne attenuation at high frequencies unless combined with mass layers. Understanding the distinction helps you request the right metrics for your use case—vehicle cabin, machine enclosure, or floor underlayment.

Material properties that determine acoustic behavior

Key material attributes—density, dynamic stiffness, loss factor, and thickness—directly influence sound absorption and damping performance. Butyl rubber offers high internal damping (loss factor) and good conformability, making it effective at dissipating vibrational energy. However, density and mass are major contributors to low-frequency airborne attenuation. Request tests that report frequency-dependent results (not just single-number ratings) to see performance across the spectrum.

Installation and substrate effects

Test outcomes depend heavily on installation: bond quality, surface preparation, backing materials, and clamp/seal details. Some lab tests use rigid, standardized test fixtures; field conditions vary. Always ask for both standardized lab tests and in-situ measurements (field insertion loss, ISO 16283 variants) that reflect the intended substrate—car body panels, steel machine frames, concrete floors, or wooden subfloors.

Key acoustic tests buyers should request

Transmission Loss and Sound Transmission Class (STC)

Transmission Loss (TL) measures how much sound energy is reduced when passing through an assembly; Sound Transmission Class (STC) is a single-number rating derived from TL in a defined frequency range. For rubber mats, TL tests are most meaningful when the mat is part of an assembly (e.g., mat + sheet metal). The standard laboratory method for airborne transmission is covered by standards such as ASTM E90 and related ISO procedures. Request frequency-dependent TL curves (125 Hz–4000 Hz) and the calculated STC when available. For details on these standards, see ASTM references and general acoustics guidance from authoritative sources such as the Acoustical Society of America (acousticalsociety.org) and ISO acoustics overviews (ISO: Acoustics).

Impact Insulation Class (IIC) and structure-borne tests

IIC evaluates a floor/assembly's resistance to impact sound (e.g., footsteps). For rubber mats used as underlayment or in flooring systems, IIC or similar metrics indicate how effective the mat is at reducing impact noise. For mechanical equipment or vehicle panels, request structure-borne insertion loss and measuring techniques for vibration transmissibility. International field methods akin to ISO 16283 (field measurement of sound insulation) help gauge real-world performance. The distinction between lab IIC and field performance should be clear in test reports.

Insertion loss and noise reduction coefficients (NRC)

Insertion loss quantifies the reduction in sound level when a damped component is added to a system—useful for panels, doors or enclosures where rubber mats are applied. For absorptive underlays or acoustic mats inside enclosures, ask for absorption coefficients (alpha values) across octave bands or the single-number Noise Reduction Coefficient (NRC). These metrics help predict the mat's contribution to reverberation control inside compartments or rooms.

Mechanical and durability tests that affect long-term noise control

Dynamic stiffness and loss factor measurements

Dynamic stiffness (s') and loss factor (eta) are critical for resilient layers used to decouple vibration. Lower dynamic stiffness generally improves impact isolation at low frequencies. Loss factor measures internal energy dissipation—higher values indicate better damping. Request test data over a range of temperatures and frequencies relevant to the application (e.g., -20°C to +80°C for automotive). These tests are often performed per national or industry test methods or specialized laboratory protocols.

Environmental aging: temperature cycling, humidity, and UV

Rubber mats in vehicles or outdoors face heat, cold, humidity, and UV exposure. Ask for accelerated aging tests (thermal cycling, humidity exposure, UV exposure) with pre- and post-aging acoustic and mechanical measurements. These results show how compression set, adhesion, and damping properties evolve. Suppliers should provide ΔTL, ΔIIC, and retention of dynamic stiffness after aging.

Adhesion, compression set, and fatigue tests

Adhesion testing (peel strength) ensures mats remain bonded to the substrate. Compression set and fatigue (repeated load cycling) determine whether the mat will maintain thickness and resilience—key for long-term impact performance. For automotive mats, automotive OEM standards or ASTM D3330 (peel adhesion) and ASTM D395 (compression set) are frequently cited; request measured values and test conditions used.

How to interpret test reports and specify acceptance criteria

Reading frequency-dependent charts

Single-number ratings (STC, IIC, NRC) are convenient but hide important frequency-dependent behavior. Review TL, insertion loss, or loss factor curves across the full band (often 20–5000 Hz depending on the standard). For low-frequency problems (engine rumble, mechanical tones), low-frequency points around 63–250 Hz are especially important. Ask suppliers to provide raw octave- or one-third-octave-band data so you can model combined assemblies.

Typical acceptance thresholds by application

While thresholds vary by application, the following are practical guidance points to request in specifications:

- Automotive interior/door panels: insertion loss of 5–10 dB in mid-high frequencies; measurable loss factor >0.1 at 200–2000 Hz depending on mat thickness.

- Machine enclosures: TL improvement ≥6–12 dB across critical frequency bands; adhesion ≥1.5–3.0 N/mm depending on surface.

- Floor underlayment for residential: ΔIIC improvement ≥10 points (lab) for assemblies incorporating the mat.

These are starting points—final acceptance criteria should be based on acoustic goals, regulatory requirements, and substrate constraints.

Example comparison table: tests, purpose, standards, and why you should request them

| Test | Purpose | Common Standard | What to request |

|---|---|---|---|

| Transmission Loss (TL) / STC | Airborne sound attenuation of assembly | ASTM E90 / ISO procedures | Frequency-dependent TL curve (125–4000 Hz), assembly description, STC |

| Impact Insulation Class (IIC) | Impact/structure-borne noise for floors | ASTM E989 (rating), ISO variants | Lab IIC and field ΔIIC for installed system |

| Insertion Loss (IL) | Noise reduction after adding mat to panel or enclosure | Field/Lab specific protocols | One-third-octave IL across 20–5000 Hz |

| Dynamic Stiffness / Loss Factor | Vibration isolation and damping performance | ISO/ASTM lab methods or proprietary vibro-acoustic labs | Frequency curves, temperature range tested |

| Adhesion / Peel / Compression Set | Bond longevity and permanent deformation | ASTM D3330, ASTM D395 | Peel strength N/mm, compression set % after X hrs at specified temp |

| Environmental Aging | Performance after heat/humidity/UV | OEM or ASTM accelerated aging methods | Pre/post acoustic and mechanical comparison |

Making practical procurement decisions and test specification language

Request test reports, not claims

Don't accept marketing statements without documented test evidence. Request certified lab reports (PDF) that include the test protocol, specimen description, fixtures, and raw band data. Prefer third-party accredited labs and ask whether tests are repeatable with different batches.

Specify assembly-level tests when possible

Because rubber mats typically improve an assembly rather than alone, require tests on the intended assembly: e.g., butyl mat bonded to 0.8 mm steel panel, or mat installed under tile on 18 mm plywood. This gives realistic performance expectations for the final product.

Balance cost, weight and acoustic gains

Butyl Rubber Sound Damping Mat offers excellent damping per unit thickness but adds weight. For automotive or aerospace applications, request mass-per-area (kg/m2) alongside acoustic gains to evaluate trade-offs. For building applications, consider fire/smoke performance and regulatory compliance—ask for relevant certificates.

References and standards (authoritative sources)

For deeper background on the standards and acoustics principles cited above, refer to authoritative sources:

- Soundproofing — Wikipedia (overview of techniques and measurement concepts)

- Acoustical Society of America (ASA) (technical resources on sound measurement and standards)

- ISO: Acoustics (overview of acoustical standards)

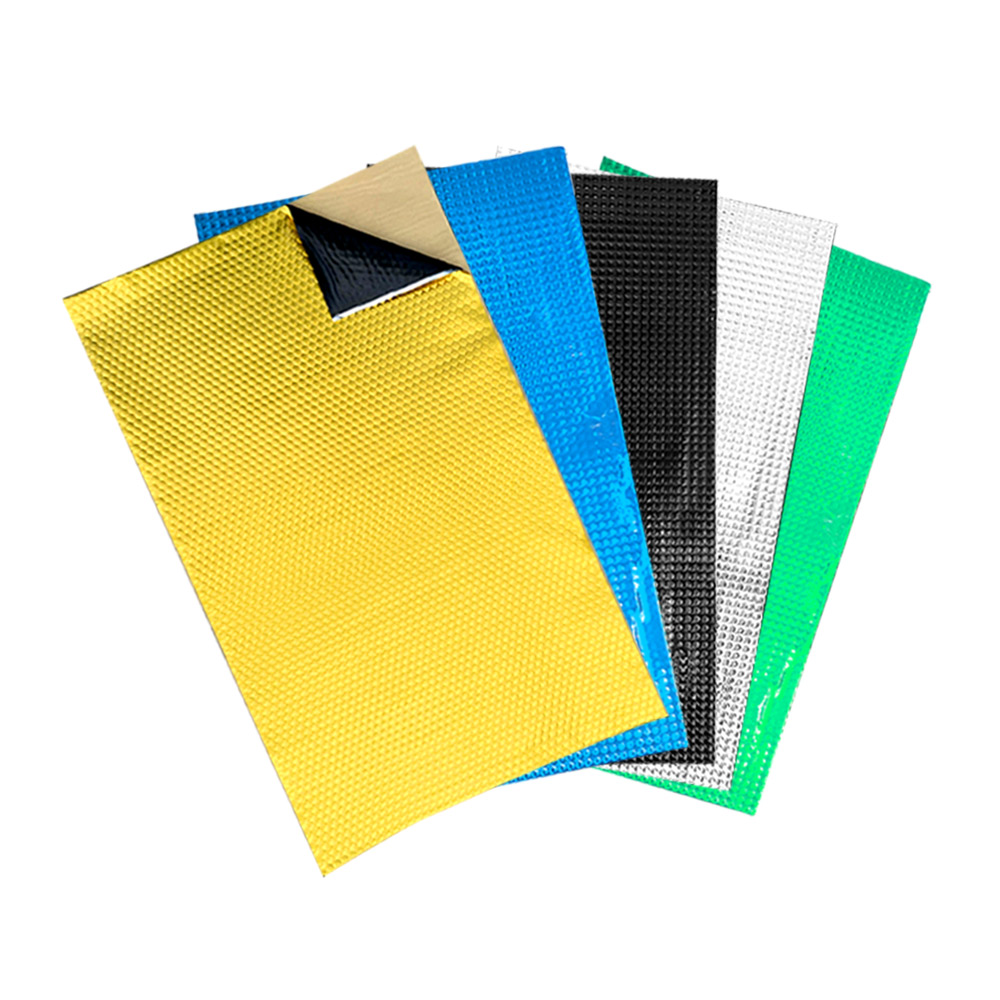

Product highlight: Butyl Rubber Sound Damping Mat

ASLONG Butyl Rubber Sound Damping Mat for sale. Effectively reduces noise and vibrations. High-quality butyl rubber ensures superior performance and durability. Ideal for automotive, industrial, and home applications.

When evaluating ASLONG Butyl Rubber Sound Damping Mat or similar rubber mats, request the tests described above—lab TL/STC for assemblies, insertion loss, dynamic stiffness and loss factor, adhesion, compression set and accelerated aging—to ensure the mat meets your acoustic and durability needs.

Frequently Asked Questions (FAQ)

Q: Which single test should I insist on first?

A: There is no single definitive test for all use cases. Begin with assembly-level Transmission Loss (TL) or insertion loss reports showing frequency-dependent data relevant to your substrate. For floors, prioritize IIC. For vibration-dominated problems, prioritize dynamic stiffness and loss factor.

Q: Are STC and IIC enough to compare mats?

A: STC and IIC are useful but limited. They are single-number summaries that can hide frequency-specific weaknesses. Always ask for full octave or one-third-octave results to evaluate low-frequency behavior and tonal responses.

Q: How do I evaluate long-term performance?

A: Require accelerated aging tests (thermal cycling, humidity, UV) with pre- and post-aging acoustic and mechanical comparisons. Also request adhesion, compression set, and fatigue test data to predict in-service behavior.

Q: Should tests be performed by third-party labs?

A: Yes—third-party accredited labs reduce bias. Request lab accreditation details and raw data so you can independently verify the test conditions and results.

Q: What if my installation substrate differs from the lab test?

A: Ask the supplier to reproduce tests on specimens that match your substrate, or perform field measurements (ISO 16283-style) after installation. Field insertion loss testing captures installation effects and real-world performance.

Need certified test data or want to see how ASLONG Butyl Rubber Sound Damping Mat performs in your specific application? Contact our technical sales team to request lab reports, sample kits, or an on-site evaluation. Contact us or view product details to order samples and technical documentation.

How to manufacturing butyl tape waterproof sealing tape

Top Sound Insulation Brands for Automotive Use 2026

What is sound insulation materials

What is sound deadening sheet

FAQs

Does ASLONG provide after-sales service?

Yes, we provide a full range of after-sales services, including technical support, installation guidance, product maintenance and quality tracking, etc., to ensure that each project goes smoothly and continues to perform at its best.

What specific functions can ASLONG's products provide?

Our products cover functions such as insulation, sound insulation, shock absorption, waterproofing and sealing, and are widely used in improving energy efficiency, reducing noise, controlling vibration, protecting equipment, etc., helping customers optimize engineering effects and improve user experience.

Do ASLONG's products meet environmental protection standards?

Yes, all ASLONG products comply with ISO14001 environmental management system certification and global environmental protection standards. We use environmentally friendly materials and are committed to providing sustainable solutions to help customers achieve green development goals.

What industries are the products provided by ASLONG suitable for?

ASLONG's products are suitable for multiple industries, including air conditioning and HVAC, construction and waterproofing, automobiles and transportation, home appliances and electronics, industrial equipment and machinery, etc. We provide customized solutions for each industry to meet different needs.

How to customize products that meet the needs of my industry?

You only need to contact our sales or technical team, we will conduct an in-depth analysis based on your industry needs and provide tailor-made products and solutions. We guarantee to provide you with efficient and accurate services to meet your personalized requirements.

Butyl Rubber Sound Damping Mat

ASLONG Butyl Rubber Sound Damping Mat for sale. Effectively reduces noise and vibrations. High-quality butyl rubber ensures superior performance and durability. Ideal for automotive, industrial, and home applications.

Mass Loaded Vinyl

ASLONG Mass Loaded Vinyl for sale. Reduce noise pollution effectively with our high-quality, mass-loaded vinyl. Ideal for soundproofing walls, floors, and more. Buy now and experience the difference!

Egg Crate Foam

ASLONG Egg Crate Foam for sale. Lightweight, breathable, and comfortable, our egg crate foam provides superior support and pressure relief. Perfect for mattresses, cushions, cars, construction industry, KTV, factories, etc.

NBR Foam

ASLONG NBR Foam: Wholesale NBR foam solutions for diverse applications. High-quality, durable, and competitively priced. Contact us today for bulk orders.

Professional support at any time

If you have any comments or good suggestions, please leave us a message; later our professional staff will contact you as soon as possible.

© 2026 ASLONG All Rights Reserved. Privacy Policy | Terms and Conditions | Sitemap

Whatsapp: +8613242879341

ASLONG Global

ASLONG

Aslong_global